Automatic tool anchor plate

An automatic tool and anchor plate technology, applied in structural elements, building components, building reinforcements, etc., can solve problems such as reducing work efficiency, and achieve the effects of saving installation time, simple and practical structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

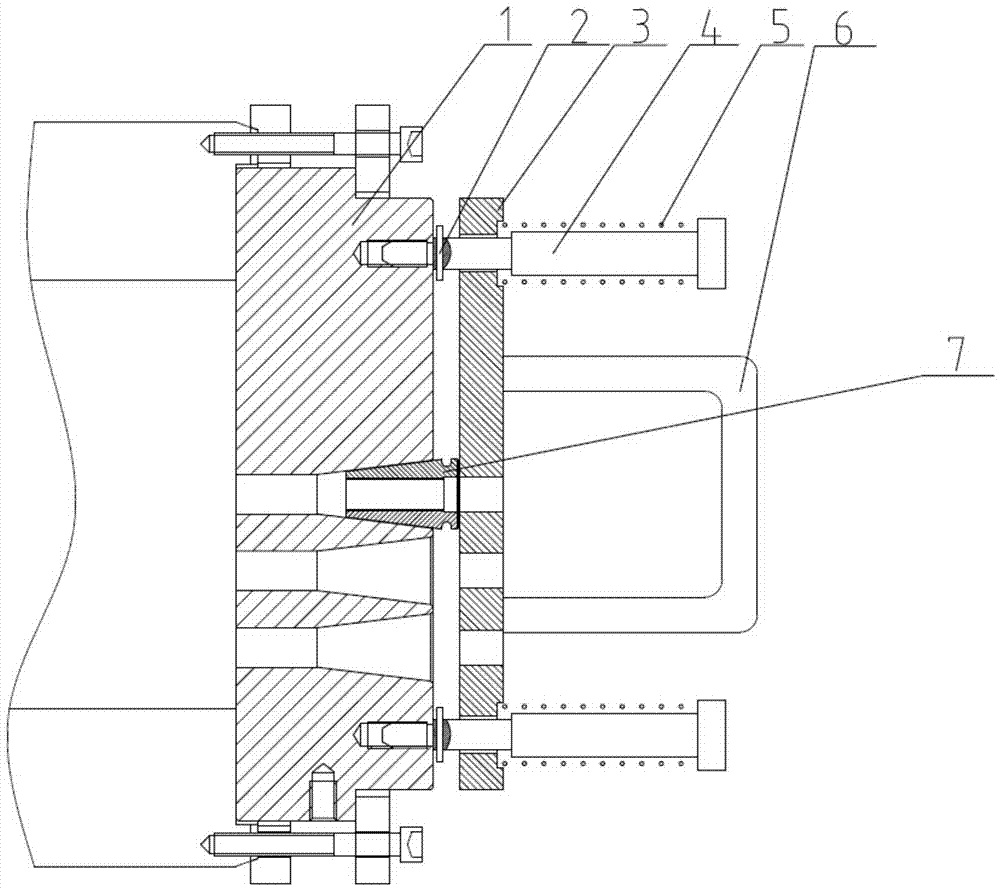

[0007] Examples of the present invention are figure 1 An automatic tool anchor plate is shown, including a tool anchor plate 1, and the automatic tool anchor plate also includes a baffle plate 3, a pin 2 connecting the tool anchor plate 1 and the baffle plate 3, and fastening the pin The fastening bolt 4 of the sub 2 and the baffle plate 3, the spring 5 sleeved on the outside of the fastening bolt 4, the tool anchor plate also includes a through hole, and the baffle plate 3 corresponds to the through hole on the tool anchor plate 1 The position is also provided with a second through hole.

[0008] The automatic tool anchor plate also includes a handle 6 connected to the baffle plate 3 .

[0009] The installation process of the present invention: firstly, the working clip is loaded into the predetermined position of the tool anchor plate 1, then the pin 2 is fixed on the tool anchor plate 1, and then the baffle plate 3 is engaged On the pin 2 , at last, the fastening bolt 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com