Mobile factory building

A plant and support column technology, applied in industrial buildings, buildings, building structures, etc., can solve the problems of poor plant performance and easy to be blown down by strong winds, and achieve the effect of saving construction materials, simple structure, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

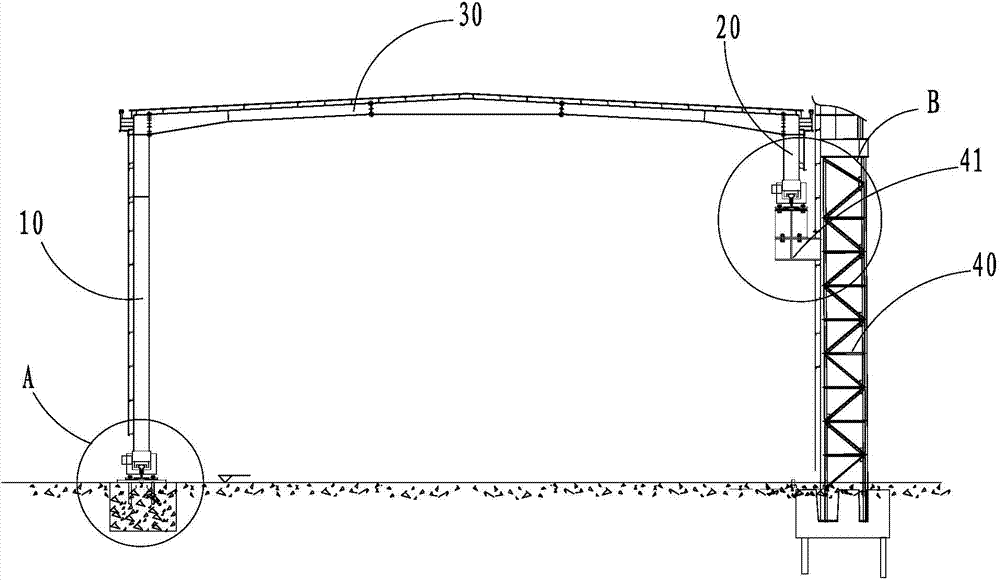

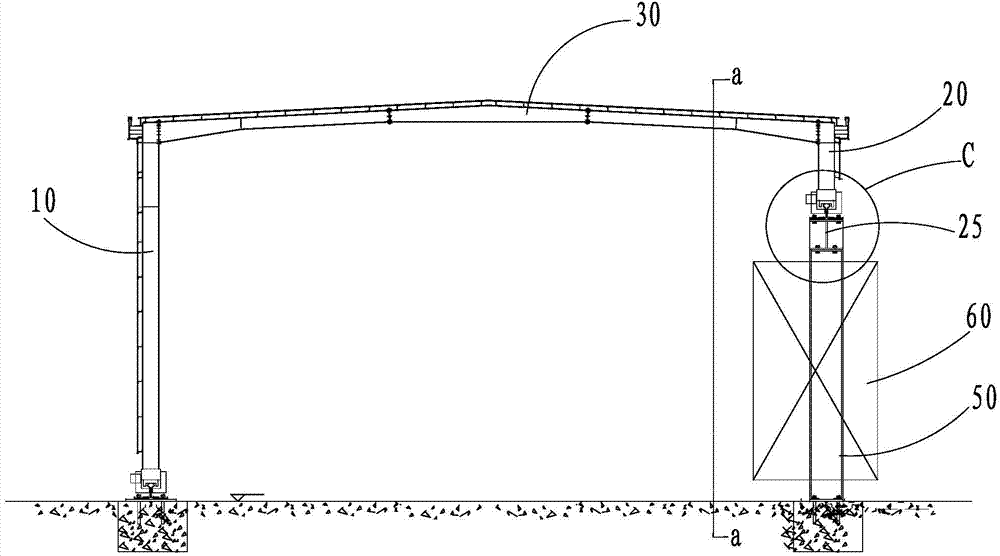

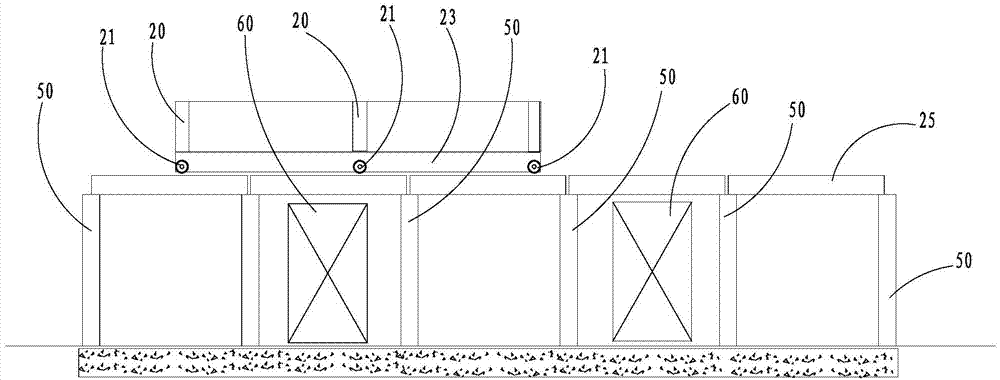

[0030] see Figure 1-6 , The mobile workshop of the present invention includes a roof beam 30 , a first support column 10 and a second support column 20 respectively located on both sides of the roof beam 30 . The first support column 10 and the second support column 20 are two or more, the first support column 10 is arranged on the guide rail 12, the second support column 20 is arranged on the guide rail 22, and the first support column Both the column 10 and the second support column 20 can move along the guide rails (12, 22). The first support column 10 is longer than the second support column 20, the guide rail 12 below the first support column 10 is fixedly installed on the foundation 15, and the guide rail 22 below the second support column 20 is fixedly installed on the auxiliary supporting structure (not shown in the figure).

[0031] In the mobile workshop of the present invention, the lengths of the first support column 10 and the second support column 20 on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com