Method for constructing enamelled storage tanks and silos

A technology for storage tanks and structures, applied in chemical instruments and methods, botanical equipment and methods, packaging, etc., can solve the problems of high-cost batch process, weak tolerance, limited storage tank height and diameter, etc., to achieve low The effect of cost production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

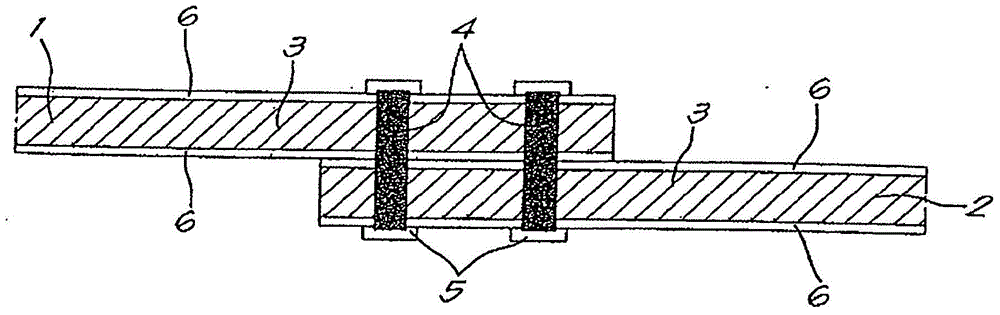

[0034] Figure 1 shows the gap between two overlapping parts of double-sided porcelain-clad steel plate sections 1, 2 of a thick-walled steel plate 3 held together by two screws 4 with bolts 5, as applied in the current state of the art. Sectional view, the two steel sheet segments have an enamel coating 6 on both sides.

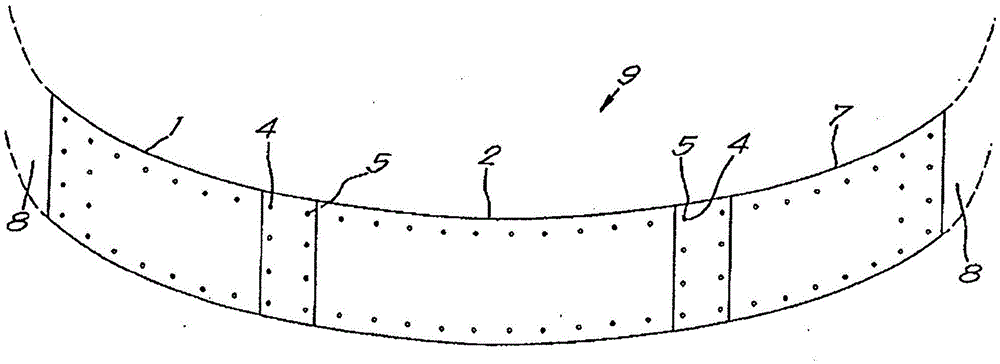

[0035] As known in the prior art, Fig. 2 shows three arc-shaped steel plate segments 1, 2, 7 screwed together with screws 4 and bolts 5, and said three arc-shaped steel plate segments form a storage The annular portion 8 is part of the tank 9 .

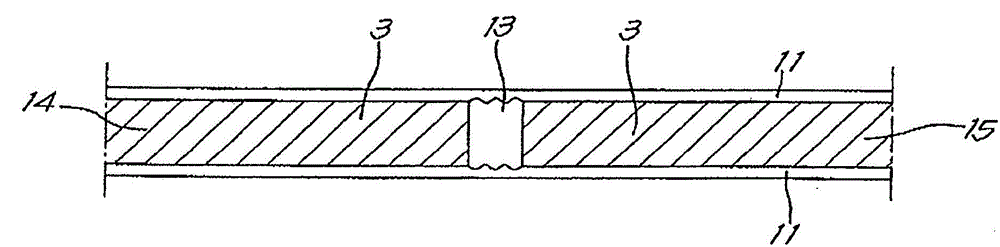

[0036] image 3 Shows a cross-sectional view of two non-ceramic steel plate sections 14, 15 of a thick-walled steel plate 3 welded together by a welded joint 13, said two non-ceramic steel plate sections being made of flexible thin-walled steel plates clad on both sides 11 is coated on the inner side and the outer side, and the double-sided ceramic-clad flexible thin-walled steel plate is glued to the thick-walled s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com