Split-type wireless liquid level detection system and its electro-corrosion suppression method

A liquid level detection, split-type technology, applied in signal transmission systems, liquid level indicators and instruments for physical variable measurement, etc. The effect of electro-corrosion, expanding the range of applications, simplifying the trouble of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

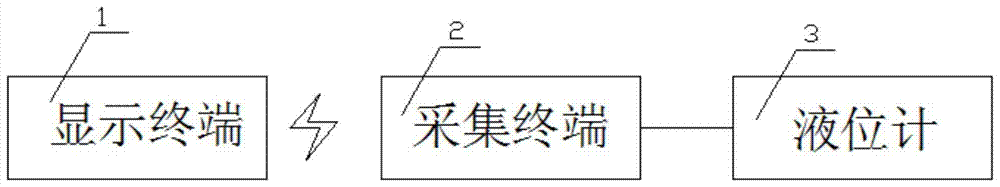

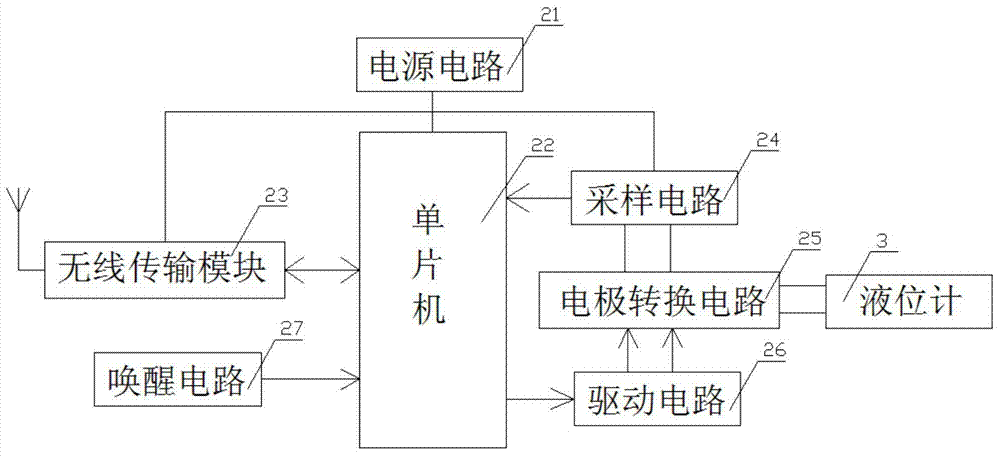

[0030] Such as figure 1 — image 3 As shown, a split-type wireless liquid level detection system is composed of a display terminal 1, an acquisition terminal 2 and a liquid level gauge 3. The liquid level gauge 3 is installed on the water supply tank of the automobile sprinkler for detecting the water supply tank The liquid level height in the liquid level meter 3 converts the liquid level state into a resistance state and is connected to the collection terminal 2 through two signal lines. A wireless transmission module 23 is arranged in the collection terminal 2. The collection terminal 2. The collected liquid level status information is uploaded to the display terminal 1 through the wireless transmission module 23.

[0031] combine image 3 It can be seen that the acquisition terminal 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com