Low compression deformation fluororubber premix and preparation method thereof

A fluorine rubber raw rubber and fluorine rubber technology, applied in the field of fluorine chemical industry, can solve the problems that the compression deformation rate has not reached the ideal level, the compression deformation has not been effectively improved, and the raw rubber preparation process is cumbersome, etc., and achieve good hot tear performance, low The effect of compression set rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

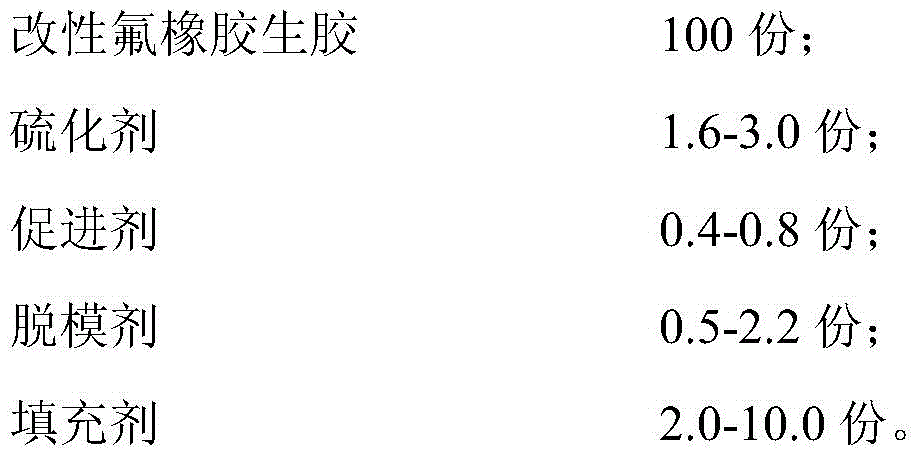

[0039] The low compression deformation fluororubber premix described in this embodiment is made of the following raw materials in parts by weight:

[0040]

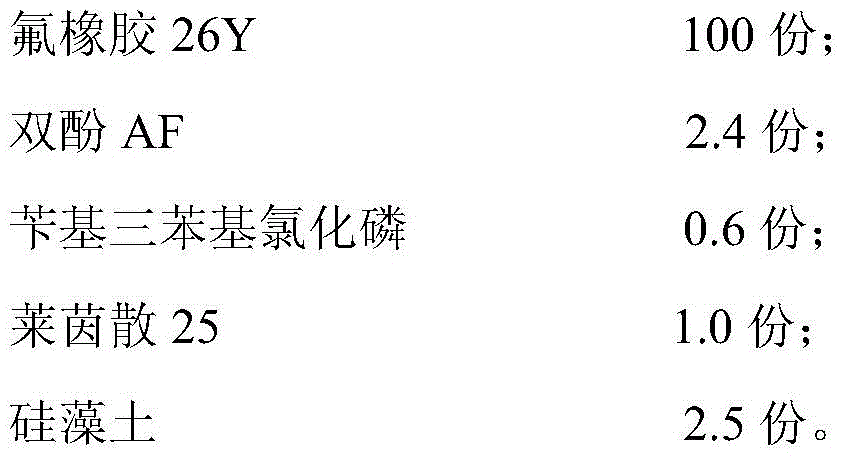

[0041] The preparation method is as follows: thinly pass the fluororubber 26Y in the internal mixer for 10 times, and the roller temperature is 25°C; then add bisphenol AF, benzyl triphenylphosphine chloride, Rhine powder 25 and diatomaceous earth for pre-mixing 3 minutes, the temperature is controlled at 35°C; the triangular bag is thinned and passed 10 times on the open mill, the temperature of the roller is 35°C, and the sheet is discharged to obtain a low compression deformation fluororubber premixed rubber.

Embodiment 2

[0043] The low compression deformation fluororubber premix described in this embodiment is made of the following raw materials in parts by weight:

[0044]

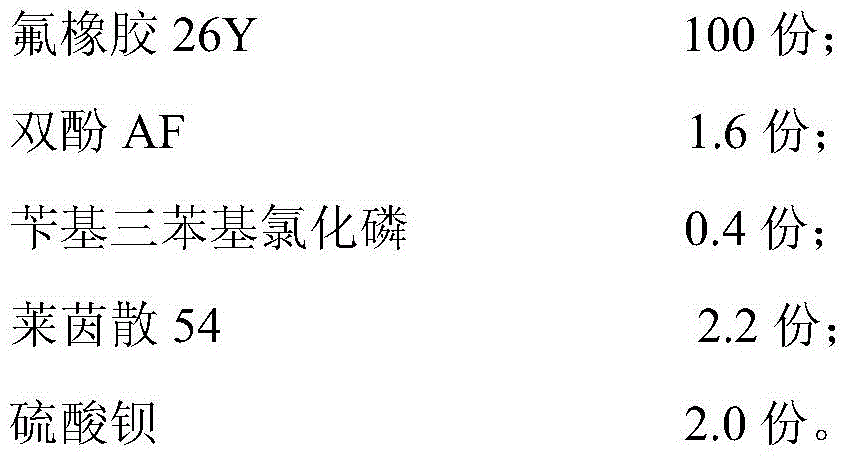

[0045] The preparation method is as follows: thinly pass fluororubber 26Y in the internal mixer for 12 times, and the roller temperature is 30°C; then add bisphenol AF, benzyl triphenylphosphine chloride, Rhine powder 54 and barium sulfate for pre-mixing for 5 minutes , the temperature is controlled at 35°C; the triangular bag is thinned and passed 15 times on the open mill, the temperature of the roller is 50°C, and the sheet is discharged to obtain a low compression deformation fluororubber premixed rubber.

Embodiment 3

[0047] The low compression deformation fluororubber premix described in this embodiment is made of the following raw materials in parts by weight:

[0048]

[0049] The preparation method is as follows: thinly pass fluorine rubber 246K in the internal mixer for 15 times, and the roller temperature is 50°C; then add bisphenol AF, benzyl triphenylphosphine chloride, Rhine powder 25 and calcium silicate for pre-mixing For 4 minutes, the temperature was controlled at 50°C; the triangular bag was beaten on the open mill for 12 times, the temperature of the roller was 55°C, and the sheet was discharged to obtain a low compression deformation fluororubber premixed rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com