A five-axis tool length compensation method based on post-processing

A tool length compensation and post-processing technology, applied in instruments, computer control, simulators, etc., can solve problems such as tool length compensation without five-axis tool length compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiment of the five-axis tool length compensation method based on post-processing of the present invention includes:

[0024] A. Analyze the structure of the five-axis CNC machine tool of the designated swing head turntable;

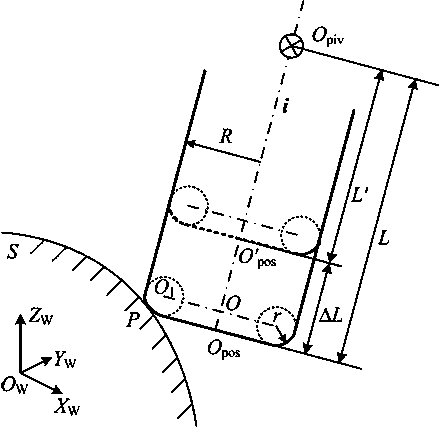

[0025] By analyzing the specific structure of the machine tool (see figure 2 ), to obtain the kinematic relationship between the coordinate axes of the machine tool, that is, the kinematic chain of the machine tool. It is composed of rotary table, translational table, bed, spindle and tool in series, such as image 3 shown.

[0026] B. According to the structure of the five-axis CNC machine tool of the swing head turntable type, the kinematics model of the five-axis CNC machine tool is established, and the corresponding inverse kinematics calculation is performed;

[0027] In order to describe the movement between the coordinate axes of the machine tool, establish Figure 4 The machine coordinate system shown. in O m X m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com