Method for determining a physical and/or chemical, temperature dependent, process variable

A technology for determining process and process variables, applied in the field of process variables, to solve problems such as unpredictable drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

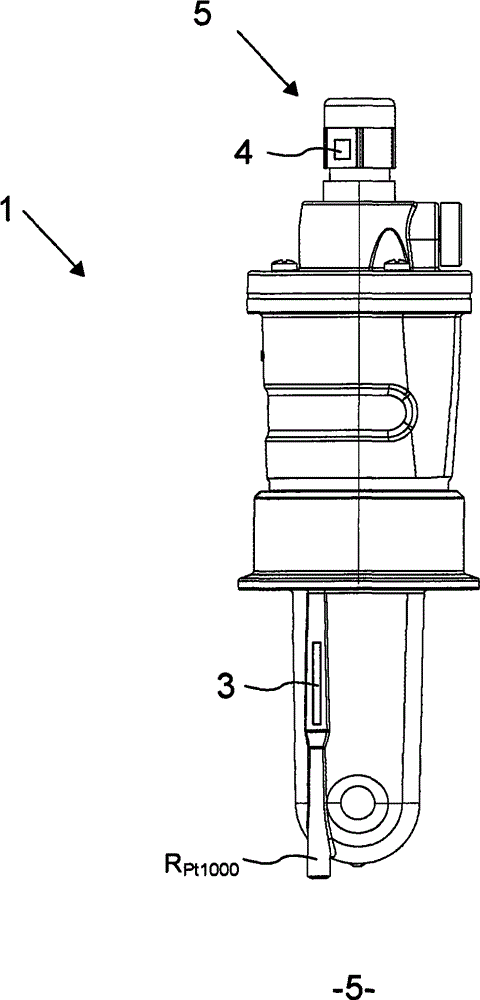

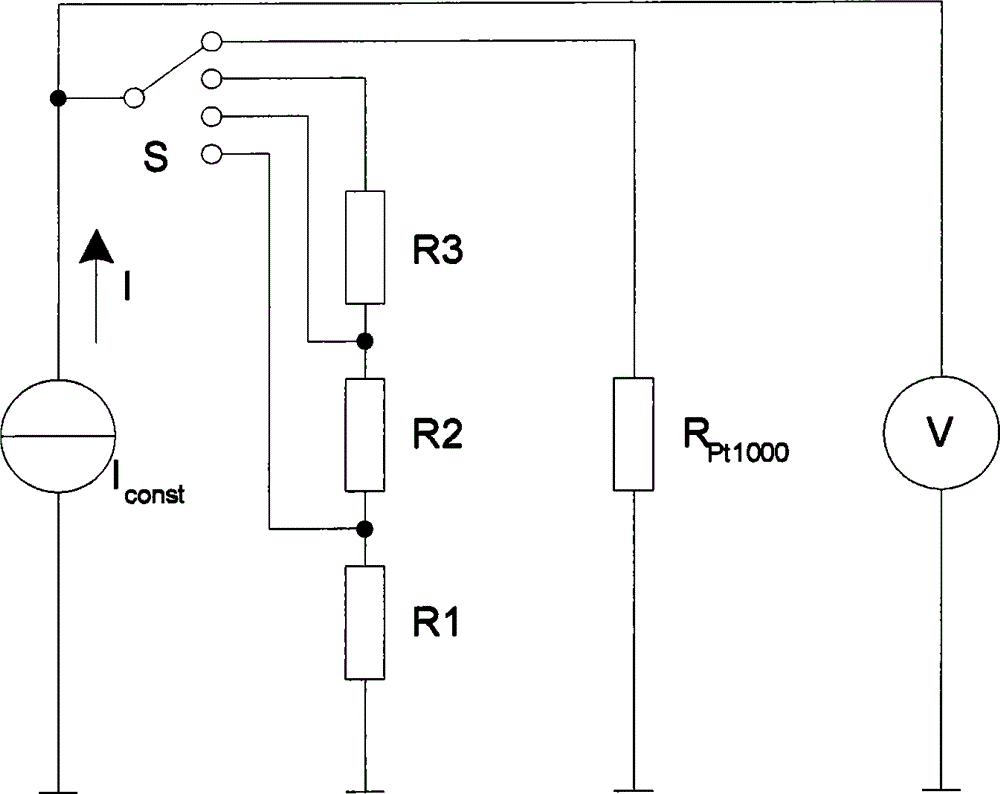

[0037] The following will be based on figure 1 The conductivity sensor 1 shown is used to explain the invention. However, the basic idea is equally applicable to other types of sensors for measuring physical or chemical process variables. These sensors are mainly used in the field of process automation. A wide variety of sensors are therefore available for measuring various parameters of the medium 5 , these parameters being generally temperature-dependent. In this regard, the sensor is positioned, or partially positioned, in the medium 5 to be measured or at least in contact with the medium 5 to be measured. Traditional sensors include, in this case, pH-, oxidation-, turbidity-, amino-, chloride- and conductivity sensors, among others. The basic principles of conductivity sensors are known. The measurement of conductivity is highly temperature dependent, therefore, each conductivity sensor also includes a resistance thermometer R Pt1000 Used to determine the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com