Firework cylinder assembling device

A technology for assembling devices and fireworks tubes, which is applied in the field of machinery, can solve problems such as low production efficiency, high labor intensity of workers, and unstable pass rate, and achieve the effects of high production efficiency, high pass rate, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

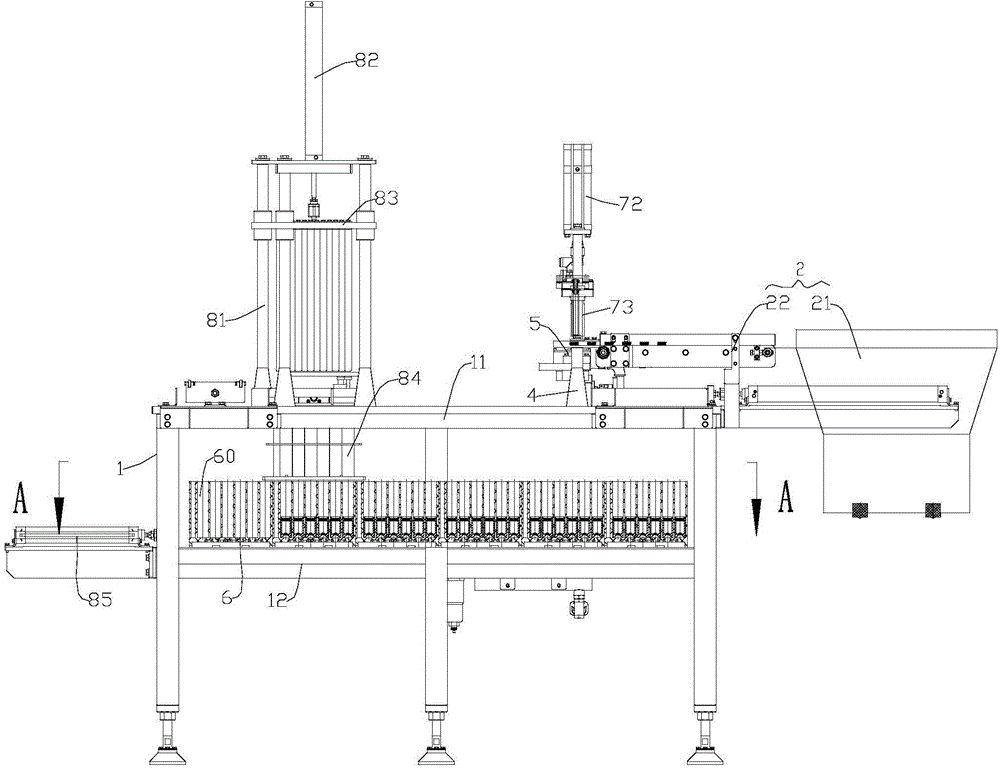

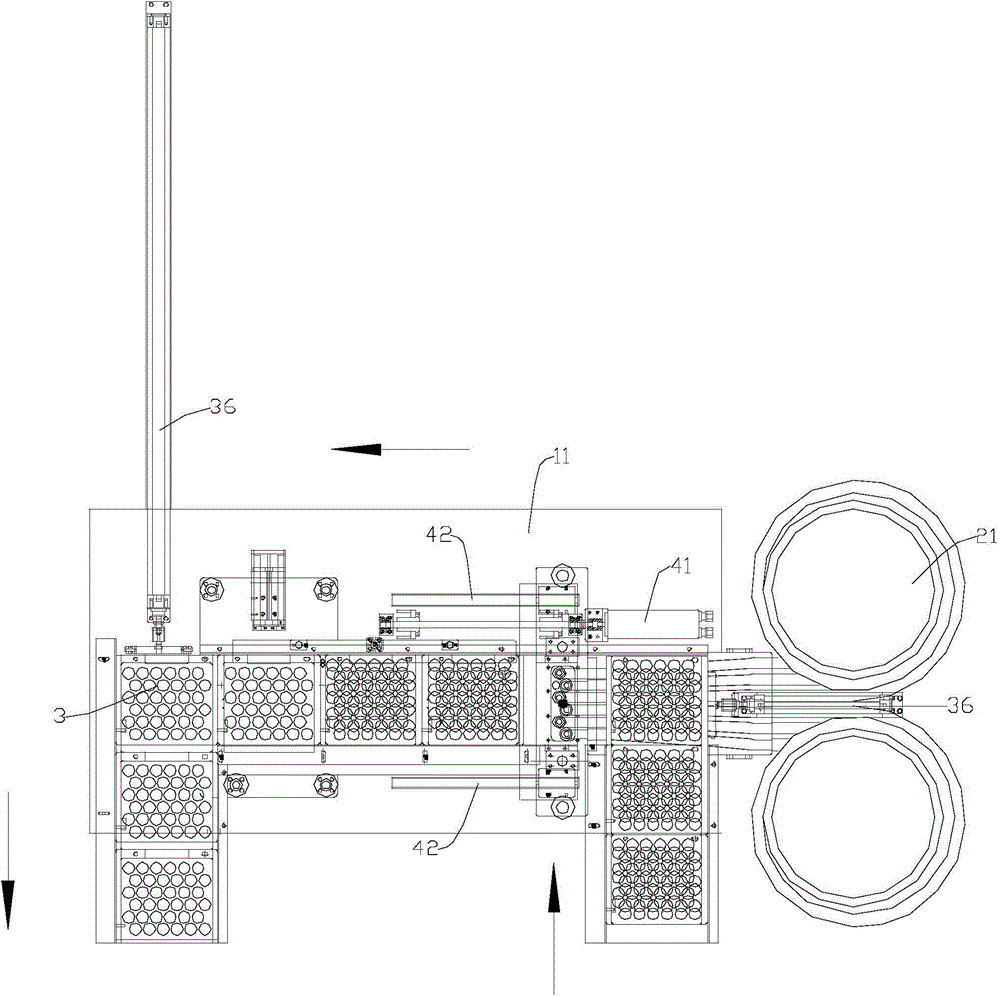

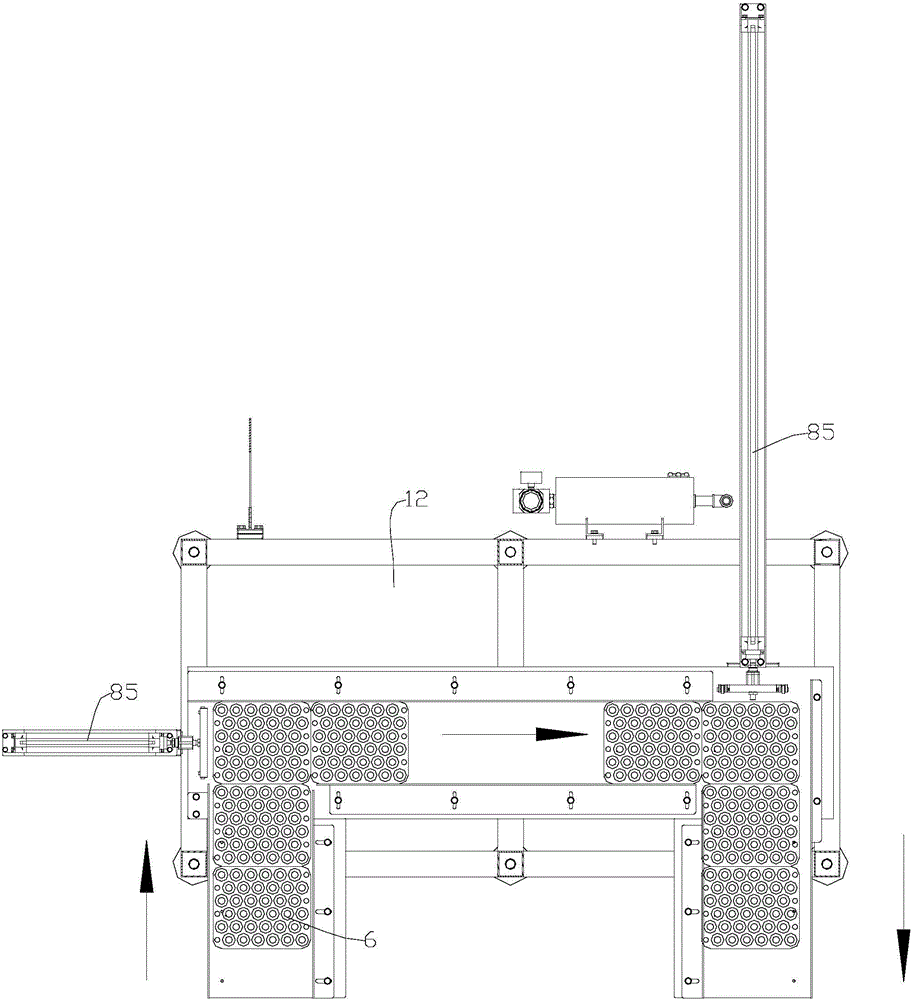

[0037] refer to figure 1 , figure 2 ,as well as image 3 , the preferred embodiment of the present invention provides an assembly device for a firework tube, including a workbench 1, an upper cover assembly 2, a glue gland assembly, and a blanking basin assembly; the workbench 1 is arranged on the ground, and it includes The upper platform 11 and the lower platform 12 are set up and down in sequence, and the upper platform 11 is sequentially provided with an upper cover station, a glue pressing station, and a blanking and potting station along its length direction; the upper cover assembly 2 is arranged on the upper At the capping station, it includes a cap sorting bucket 21, and a cap removing seat 22 connected with the cap sorting bucket 21 for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com