Gear shifting control mechanism and automobile

A control mechanism, automobile technology, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problem of inability to determine the shift shaft to switch in place, and achieve the effect of improving hand feeling strength and strong inhalation feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The gear shifting mechanism provided by the embodiments of the present invention adds an auxiliary torque to the gear shifting structure on the basis of not changing the gear shifting structure itself, and the auxiliary torque can provide a suction feeling for the gear shifting process.

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples.

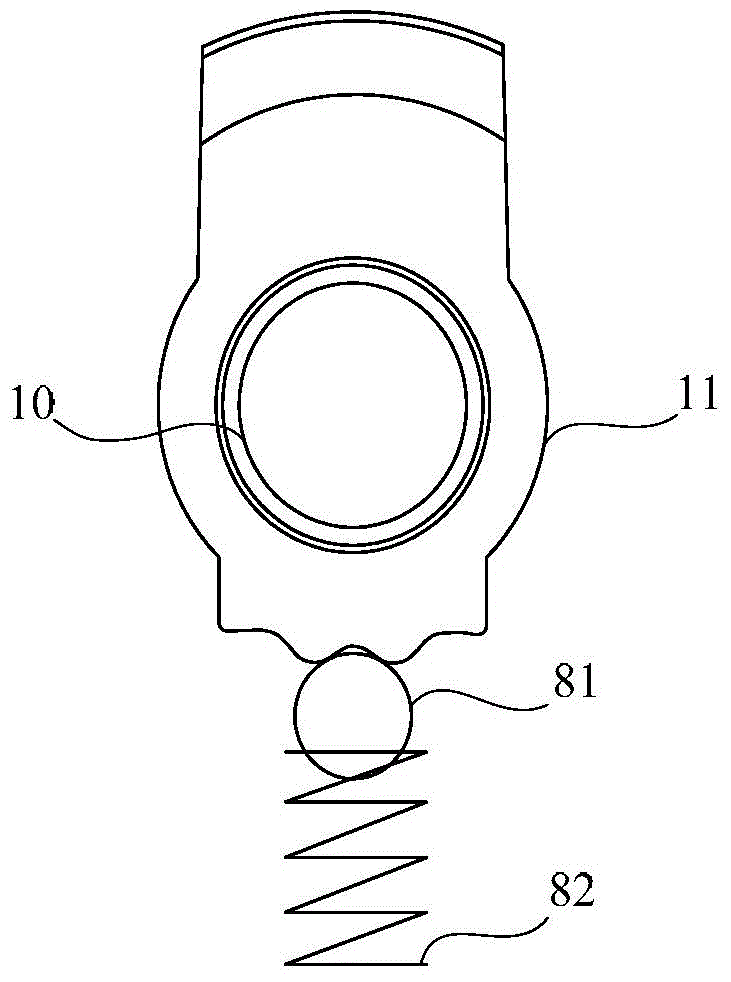

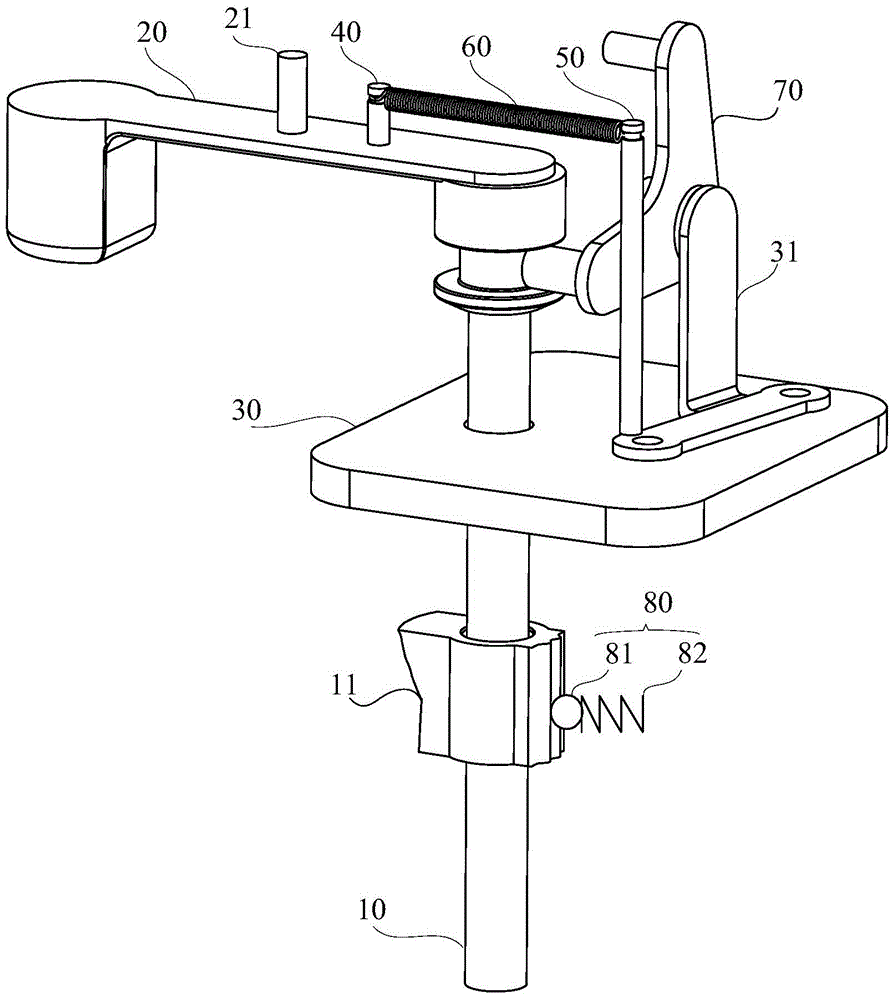

[0039] image 3 The preferred embodiment provided by the invention is shown. from image 3 It can be seen from the figure that in the preferred embodiment of the present invention, the shifting mechanism includes a shifting shaft 10, a shifting structure 20 connected to one end of the shifting shaft 10, and a shifting structure 70, and the rotation of the shifting structure 70 can make the shif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap