A test method for liquid-cooled motor

A technology of liquid-cooled motor and test method, applied in the direction of motor-generator testing, etc., can solve the problems of damage to the liquid-cooled casing, cooling pipeline, motor stator, motor rotor, etc., and achieve the effect of meeting product-related performance testing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

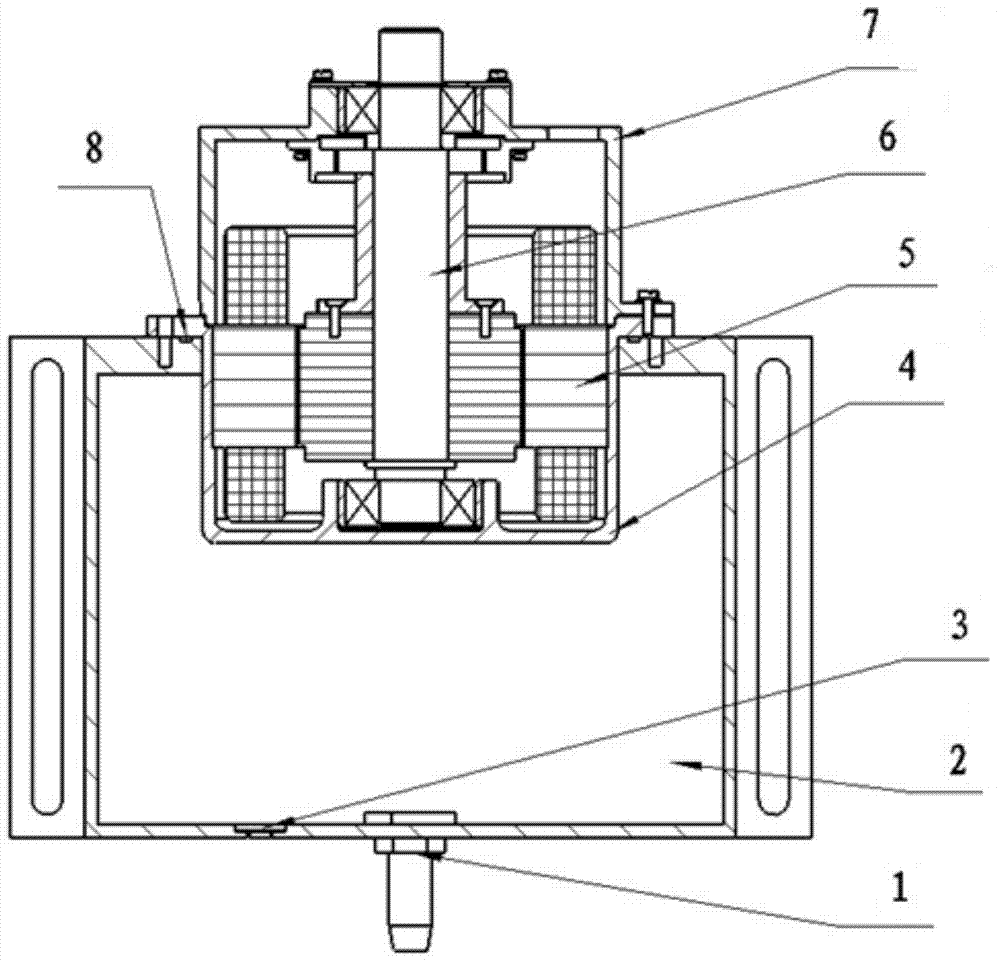

[0016] The outer diameter of the stator of a certain type of motor is 158mm, the length of the stator core of the motor is 57mm, and the rated output power is 22kW; the parameters of the designed motor shell are as follows:

[0017] The small diameter of the motor rear housing flange is 156mm; the major diameter of the motor rear housing flange is 158.5mm; the distance from the motor rear housing flange to the opening is 56mm; the outer diameter of the motor rear housing is 166mm; the inner edge of the motor front housing opening is 154mm; the opening of the water tank installation hole is 167mm.

[0018] The ambient temperature is 25°C, the cooling water temperature is 22°C, and the motor works at 22kW output power for 10 minutes after starting. The measured motor stator winding temperature is 95°C, which meets the product function test requirements.

Embodiment 2

[0020] The outer diameter of the stator of a certain type of motor is 100mm, the length of the stator core of the motor is 80mm, and the rated output power is 9kW; the parameters of the designed motor shell are as follows:

[0021] The small diameter of the motor rear housing flange is 98mm, the major diameter of the motor rear housing flange is 100.4mm, the distance from the motor rear housing flange to the opening is 78mm, the outer diameter of the motor rear housing is 108mm, and the inner edge of the motor front housing opening is 95mm, the tank mounting hole opening is 109mm.

[0022] The ambient temperature is 22°C, the cooling water temperature is 20°C, and the motor works at an output power of 9kW for 10 minutes after starting. The measured motor stator winding temperature is 82°C, which meets the product function test requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com