Vision measurement technology-based catenary geometric parameter measurement instrument and detection method

A technology of visual measurement and geometric parameters, applied in instruments, measurement devices, optical devices, etc., can solve the problems of inability to overcome bumps, shocks and vibrations of locomotives, inconvenient for catenary construction and emergency repairs, and inability to become reliable measurement data, etc. , to achieve the effect of convenient and fast up and down the track, convenient construction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

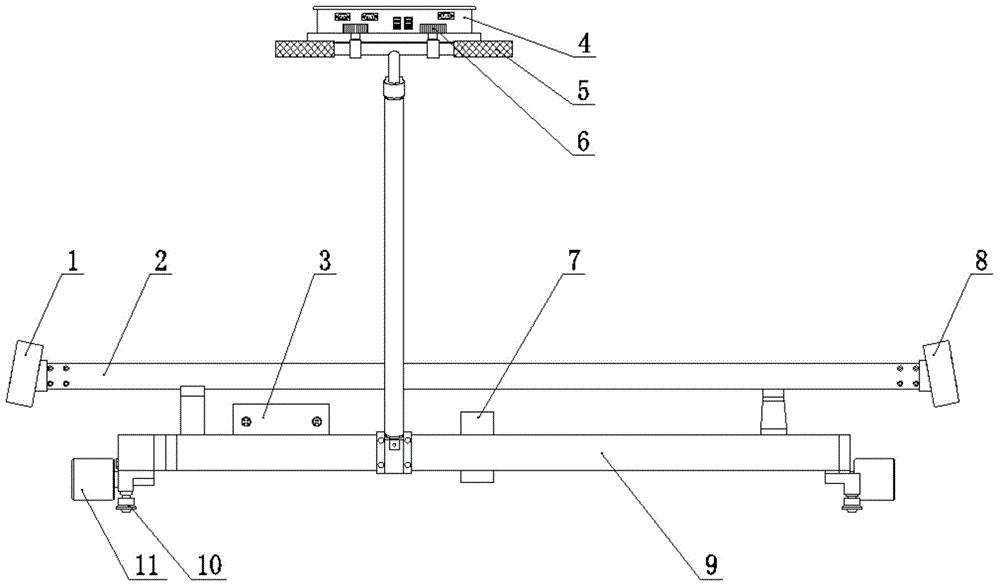

[0038]The present invention is based on precision mechanical design, takes computer vision measurement as the core, and combines the requirements of the industrial site environment to develop a precision measuring instrument that can be used on site; The in-depth and precise measurement of the catenary status constitutes the early warning system for driving safety of the catenary system.

[0039] The measurement system consists of a binocular stereo measurement component and a trolley, and is equipped with sensors for track gauge measurement, mileage measurement, level measurement, etc., and uses an industrial computer as a data processing center and human-machine interface; the specific structure is as follows:

[0040] The catenary geometric parameter measuring instrument based on visual measurement technology, including a measuring trolley 9, a baseline 2 connected to it is horizontally provided on the measuring trolley 9, and a left camera connected to it is respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com