A prefabricated thermal insulation integrated wall panel

A prefabricated, wall panel technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of wall panel ventilation, heat preservation and strength defects, and achieve the effect of simple and reliable production process, firm structure and enhanced structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

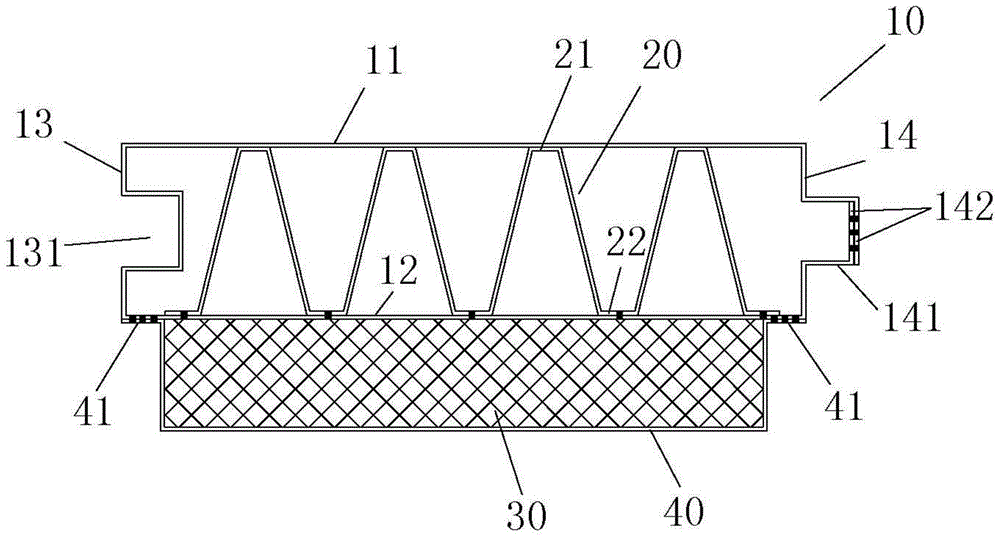

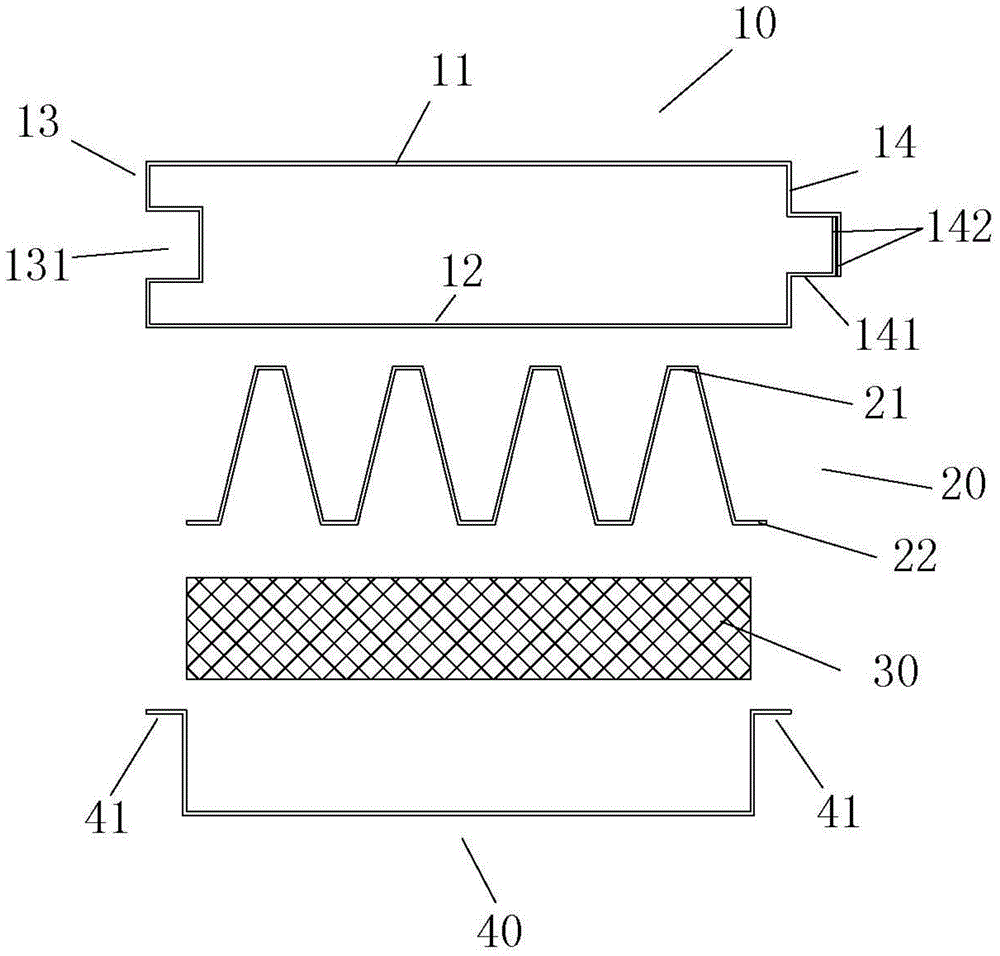

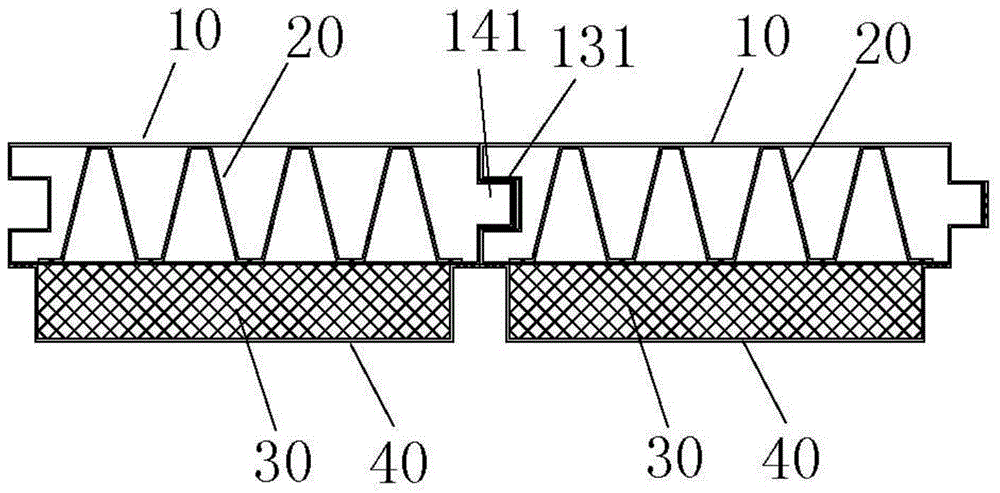

[0023] Attached below Figure 1-5 The specific implementation manner of the present invention will be described in further detail.

[0024] Such as Figure 1-3 Embodiment 1 of the present invention, a prefabricated thermal insulation integrated wallboard includes:

[0025] A metal outer frame plate 10, the metal outer frame plate 10 is cold-formed from a whole metal flat plate into a four-sided closed profile with an outer wall surface 11, an inner wall surface 12, an inner end surface 13, and an outer end surface 14, wherein, The outer wall surface 11 is parallel to the inner wall surface 12, the inner end surface 13 is formed with an inner concave portion 131 by cold folding, and the outer end surface 14 is formed with an outer convex portion 141 after cold folding, and the two edges of a whole metal plate are overlapped by cold folding to form The outer end folded surface 142 of the protruding portion 141 is formed into a four-sided closed profile by laser penetration wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com