Mixer truck for automatic control of concrete storage

A concrete and storage capacity technology, which is applied in the direction of control devices, cement mixing devices, clay preparation devices, etc., can solve the problems of waste of electric energy, poor stability, uneven pouring, etc., and achieve reduced labor intensity, high adaptability, and uniform pouring of concrete Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

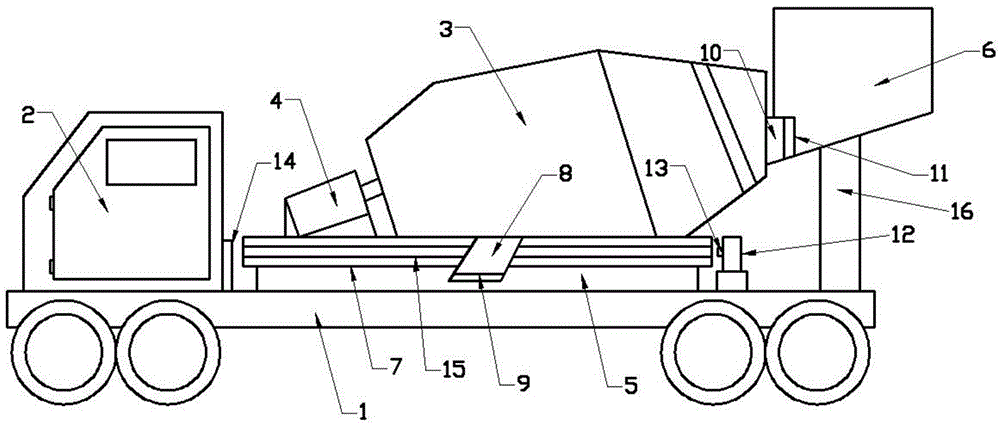

[0024] Embodiment 1: Please refer to the accompanying drawings, a mixer truck that automatically controls the storage capacity of concrete, including a chassis 1, a control room 2, a mixing tank 3, a motor 4 and a storage box 6; the chassis 1 is equipped with a control room 2 And base plate 7, elastic device 5 is arranged between base plate 7 and chassis 1, and elastic device 5 is a leaf spring, or is supported by several helical springs, makes base plate 7 move up and down under the effect of elastic device 5; There is a through hole 15 connecting the left end surface and the right end surface of the bottom plate 7 inside. The inner surface of the through hole 15 is polished and polished, and the surface is smooth and easy to reflect light; infrared devices are installed on both sides of the bottom plate 7. The infrared device includes infrared emission 13 and an infrared receiver 14, the infrared emitter 13 is located at the right end of the base plate 7, the infrared emitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com