One-eighth scanning LED display screen resistor blanking circuit

A technology of LED display screen and blanking circuit, which is applied to static indicators, instruments, etc., can solve the problem of complex blanking circuit and high cost, and achieve the effect of simple structure, solving smear, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

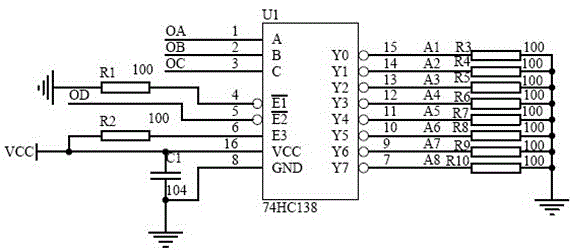

[0034]An eighth-scan LED display screen resistance blanking circuit, including a decoder U1, first to tenth resistors, and a capacitor C1, the decoder U1 includes a power supply terminal VCC, a ground terminal GND, a first control terminal A, the second control terminal B, the third control terminal C, the first enabling terminal E1, the second enabling terminal E2, the third enabling terminal E3, the first to the eighth output terminals, the power supply terminal VCC and A capacitor is connected between the ground terminals GND, the first control terminal A is connected to the first control signal OA input from the outside, the second control terminal B is connected to the second control signal OB input from the outside, and the third control terminal C is connected to the third control signal input from the outside. Signal OC; the first enable terminal E1 is connected to one end of the first resistor R1, the other end of the first resistor R1 is grounded, the second enable te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com