Sight of hunting gun

A technology for sights and shotguns, applied to the field of shotgun sights, can solve the problems of cost reduction, occupying space on the barrel or butt, unfavorable compact design, etc., and achieves the effect of saving costs and saving head space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

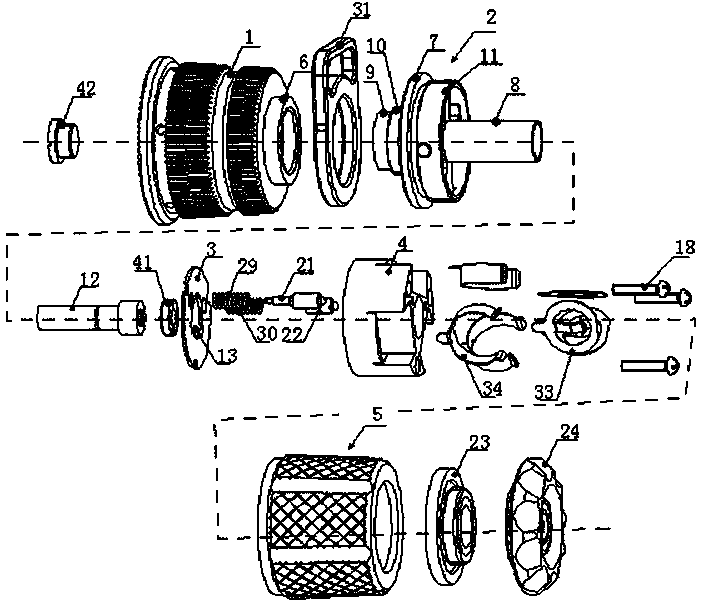

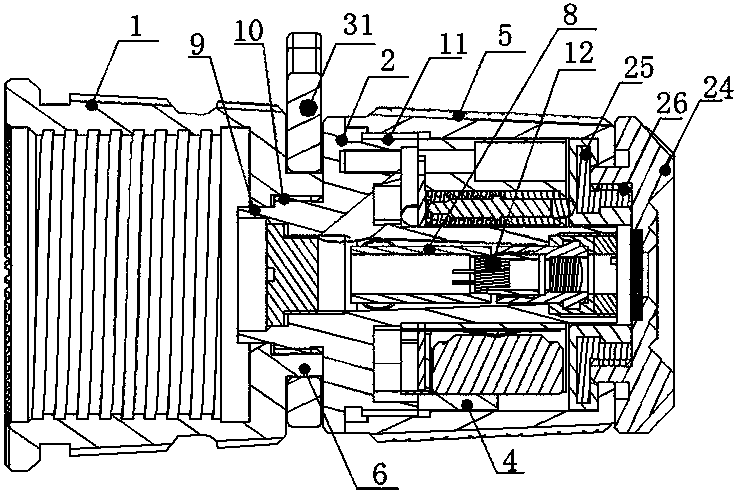

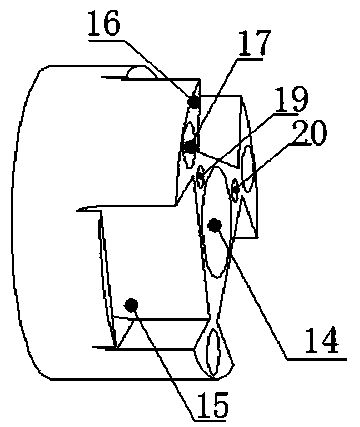

[0043] In order to save the top space of firearms and save expenses, this embodiment provides a figure 1 , 2 The shotgun sight shown includes a fixing seat 1, a laser mounting seat 2, a circuit board 3, a battery seat 4, a switch assembly, and a casing 5 arranged outside the laser mounting seat 2, the circuit board 3 and the battery seat 4, wherein, The rear end of the fixed seat 1 is provided with an internal thread, and the front end surface of the fixed seat 1 is provided with an annular retaining ring 6. The rear end of the laser mounting seat 2 is connected with the annular retaining ring 6, and the annular retaining ring 6 is sleeved with a fixed ring. The strap ring 31 between the seat 1 and the laser mounting seat 2, it is not difficult to see that the fixed seat 1 here actually plays the role of the strap connecting cap on the existing shotgun, that is, it is connected with the shotgun through the internal thread at the rear end. The connection of the bolts, realizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com