Pump water jet propeller vane wheel high in air dissolving performance

A water jet propulsion and dissolved gas technology, which is applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problem of inability to fully utilize the shear force of impeller blades, achieve high-speed effective cruise capability, improve dissolved air capability, and system Stable running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

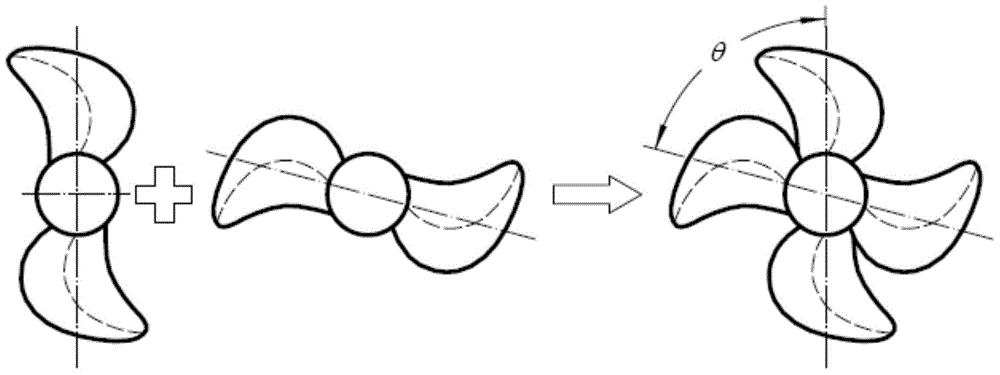

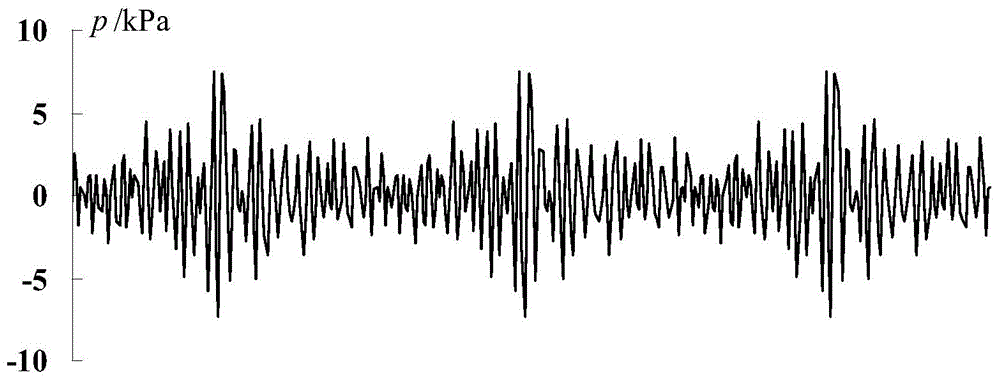

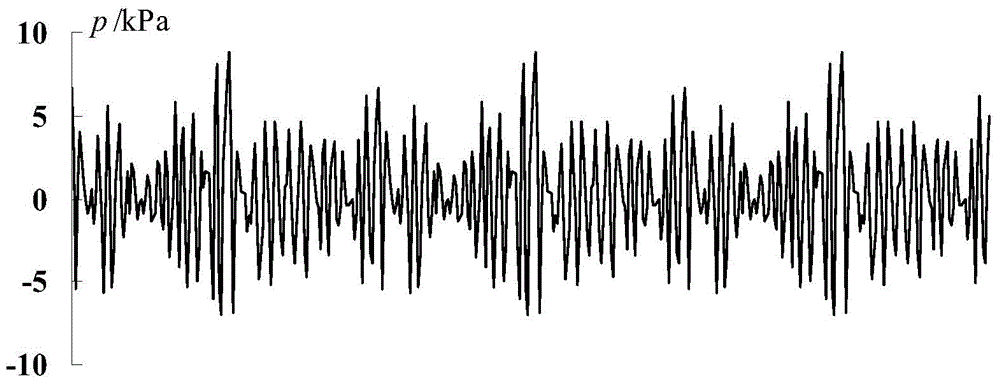

[0019] Such as figure 1 As shown, a pump water jet propeller impeller with high air-dissolving performance of the present invention includes a first blade group and a second blade group, and the first blade group and the second blade group respectively include two centrally symmetrical blades, The blades are large skewed propeller blades, the cascade density at the blade rim is 0.4, and the angle θ is formed between the first centerline where the first blade group is located and the second centerline where the second blade group is located. The angle θ is not 90°. Such as figure 2 As shown, the numerical calculation results of pressure fluctuations formed by each group of blades (two opposing blades) acting on the upstream fluid, the figure shows that the blades form periodic pressure effects on the fluid (three cycles are shown in the figure), and the maximum The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap