Columnar discharging and testing machine and method for carrying out discharging and testing on batteries through columnar discharging and testing machine

A technology of testing machine and testing organization, which is applied in primary battery, secondary battery manufacturing, circuit, etc. It can solve the problems of high labor intensity, low production efficiency, and low battery acceptance, so as to improve production efficiency and product quality. The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

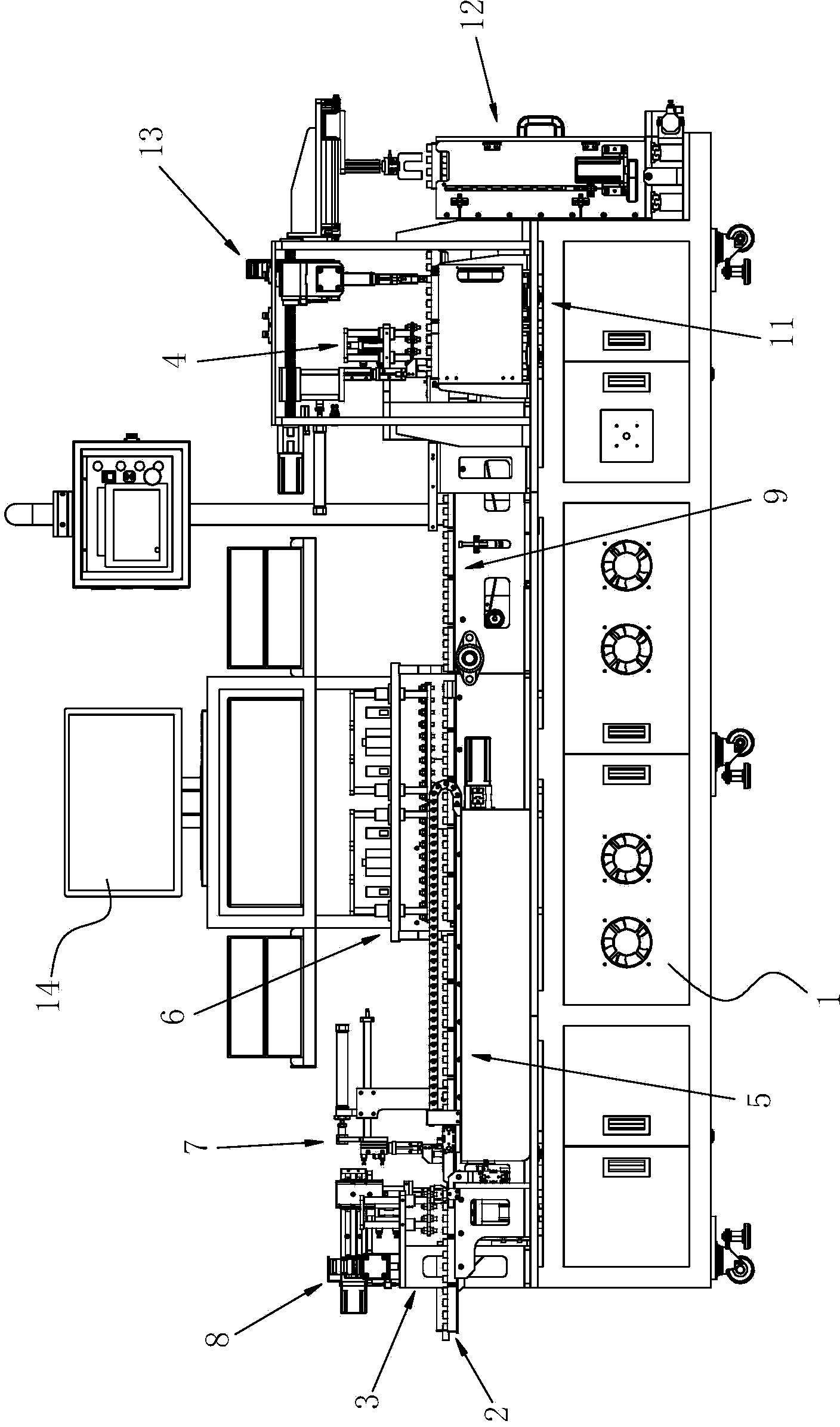

[0061] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0062] Such as Figure 1-7 As shown, in this embodiment, a column type discharge and testing machine includes an equipment frame 1, on which a discharge rail 5 for sliding the battery tray and a discharge rail for selectively discharging the battery are arranged on the equipment frame 1. The discharge mechanism 6 is located above the discharge track 5 , and the man-machine interaction component 14 is arranged above the discharge mechanism 6 . The discharge mechanism 6 includes a thimble plate 61 that can move up and down above the discharge track 5 and a conduction plate that can move up and down below the discharge track 5. The thimble plate 61 is provided with one hundred optional batteries. The abutting discharge thimble 62. When testing the battery, the thimble plate 61 moves downward, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com