In-situ self-inspection and metering device and method of automatic test system

A technology of automatic test system and metering device, applied in the direction of measuring device, measuring electricity, measuring electric variables, etc. The results lack integrity and authenticity, and achieve the effect of improving system mobility, shortening the measurement cycle, and meeting the needs of automation and informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

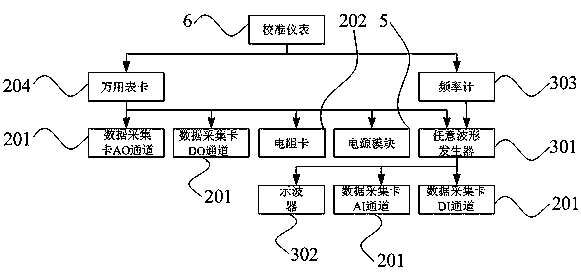

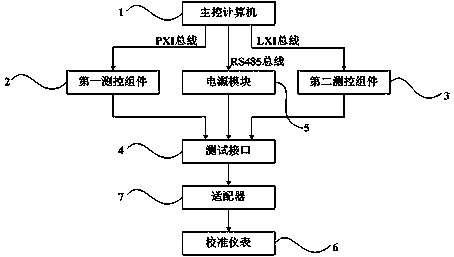

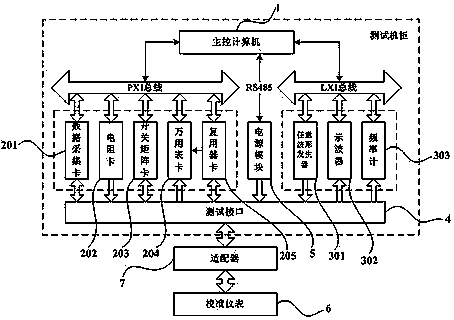

[0038] like figure 1 and figure 2 As shown, an in-situ self-checking and metering device of an automatic test system is based on the PXI and LXI hybrid bus architecture, including: a main control computer 1, which is provided by the automatic test system itself, and has a PXI bus controller and an Ethernet interface; A measurement and control component 2 is connected with the main control computer 1 through the PXI bus; a second measurement and control component 3 is connected with the main control computer 1 through the LXI bus; a test interface 4 is connected with the first measurement and control component 2 and the second measurement and control component respectively. Two measurement and control components 3 are connected; power module 5 (six program-controlled DC power supply), based on RS485 bus, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com