Winding type asynchronous motor without bearing and manufacturing method thereof

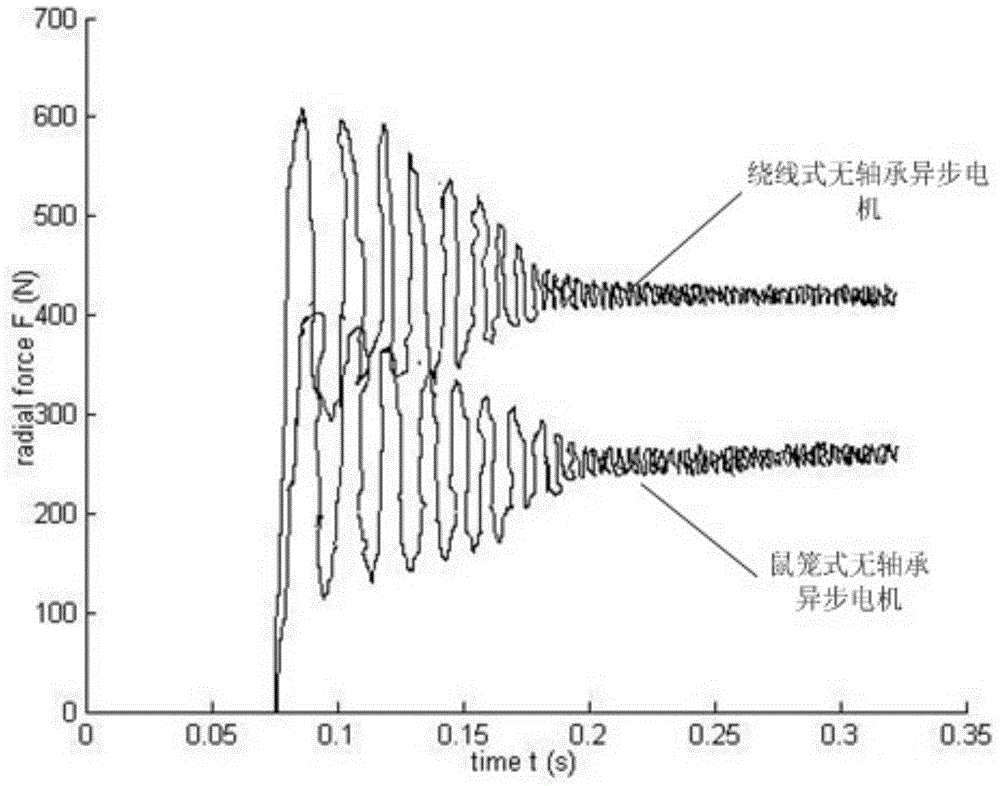

A technology of asynchronous motor and manufacturing method, which is applied to asynchronous induction motors, control generators, and manufacture of motor generators, etc., can solve the problems that the rotor control cannot be decoupled, the rotor eccentricity control is complicated, etc., and achieves the effect of reducing the complexity of the solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] like figure 1 As shown, this embodiment includes torque windings and suspension windings installed in the stator slots, and the rotor windings installed in the rotor slots, the number of stator slots is 36, the number of rotor slots is 24, and the stator adopts three-phase rotation Torque winding, the number of poles of the torque winding of each phase is 4 (the number of pole pairs is 2), the stator also adopts three-phase suspension windings, the number of poles of each phase suspension winding is 2 (the number of pole pairs is 1), and the rotor uses Three-phase rotor winding, the number of poles of each phase rotor winding is 4 (the number of pole pairs is 2).

[0026] Slots parallel to the axis on the circumference of the stator and rotor are evenly distributed along the corresponding circumference.

[0027] The u-phase torque windings (u1, u2, u3, u4) of the three-phase torque windings in the stator are arranged in slots 1, 10, 19, and 28 of the stator, and the v-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com