Large-flow block-resistant brush pen with self-provided ink

An anti-blocking, high-flow technology, applied to other ink pens, printing, writing utensils, etc., can solve the problems of inability to reuse, reduce the efficiency of ink delivery in the water guide, and difficult to control the writing effect, so as to achieve smooth delivery and meet writing needs. , Easy to dry and change the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

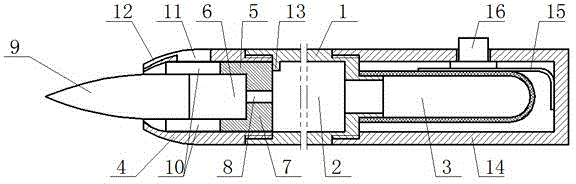

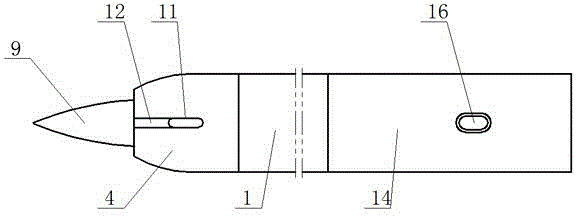

[0008] The large-flow anti-blocking brush with self-contained water described in the present invention comprises a water storage housing 1, an ink storage chamber 2 is arranged in the water storage housing 1, a capsule 3 is arranged at one end of the water storage housing 1, and the other end of the water storage housing 1 is connected to the water storage housing 1. The nib fixed sleeve 4 is connected, the inner sleeve 5 is installed in the nib fixed sleeve 4, the water outlet chamber 6 is arranged in the inner sleeve 5, the end of the inner sleeve 5 near the ink storage chamber 2 is provided with a partition 7, and a through hole is opened on the partition 7 8. The diameter of the through hole 8 is 0.5mm-3mm. The inner wall of the end of the inner sleeve 5 away from the ink storage chamber 2 is connected to the brush head 9. The side wall of the inner sleeve 5 is provided with a side water outlet gap 10, and the side water outlet gap 10 is connected to the inner sleeve The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com