Quick-frozen prepared food forming and stereotypes integrated line

A food forming, integrated technology, applied in the direction of food forming, food science, application, etc., can solve the problems of labor consumption, impact, disturbance, mechanical obsolescence, etc., and achieve the effect of high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

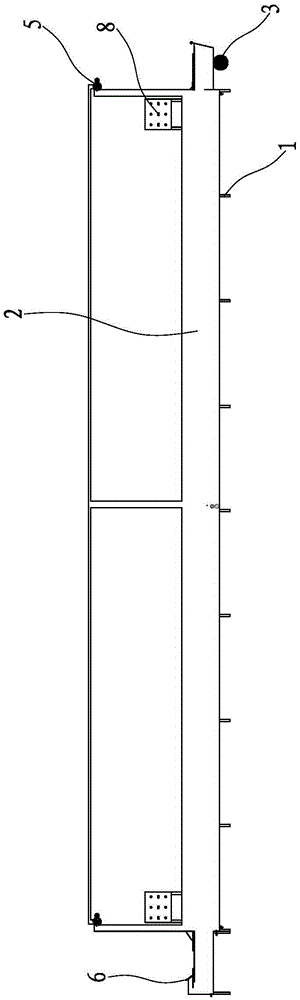

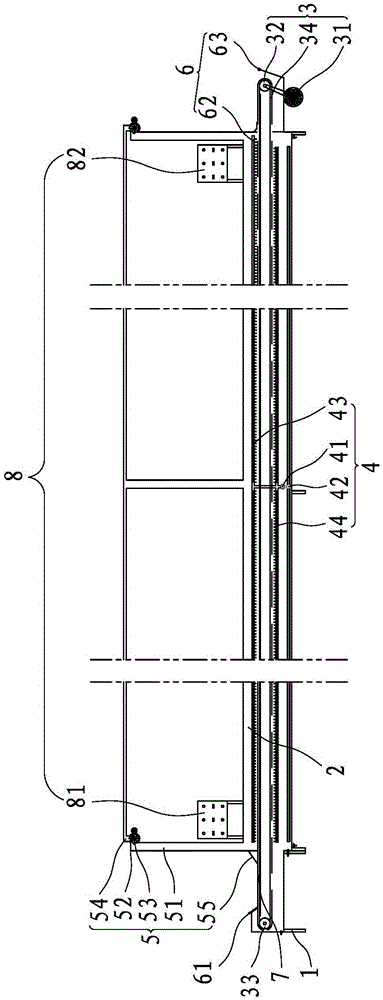

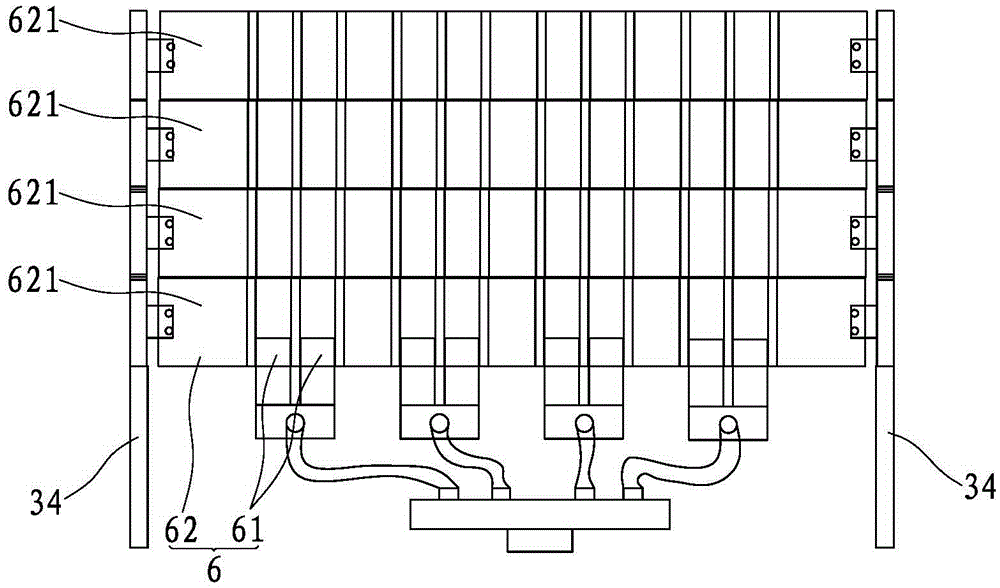

[0035] like figure 1 , figure 2 As shown, the present invention is a quick-frozen prepared food forming and shaping integrated line, including a frame 1, a tunnel-type cabinet 2, a conveying mechanism 3, a shaping mechanism 4, two sets of energy-saving mechanisms 5, a forming mechanism 6, a support rail 7, an electric control Box 8.

[0036] The conveying mechanism 3 is installed on the frame 1, the tunnel case 2 is installed on the frame 1 and covers the middle part of the conveying mechanism 3, and the shaping mechanism 4 is installed in the tunnel case 2 of the frame 1 and is located in the conveying mechanism Above and below 3, two groups of energy-saving mechanisms 5 are installed on the frame, and the steam extraction pipes 51 on the two groups of energy-saving mechanisms 5 are respectively located at both ends of the tunnel-type cabinet 2 for extracting the steam at both ends of the tunnel-type cabinet 2. Both ends of the tunnel-type cabinet 1 are open, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com