Molten iron pure spray particle magnesium desulfurization spray gun with gasification chamber on gun head and preparation method thereof

A technology of desulfurization spray gun and gasification chamber, which is applied in the field of molten iron pure spray granular magnesium desulfurization spray gun and its preparation, which can solve the problems of difficult cleaning of sticky slag on the inner wall of the gasification chamber, unstable and clogged exhaust at the side outlet, and achieve improvement. Homogeneous desulfurization reaction kinetics conditions, improvement of molten iron desulfurization reaction kinetics conditions, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

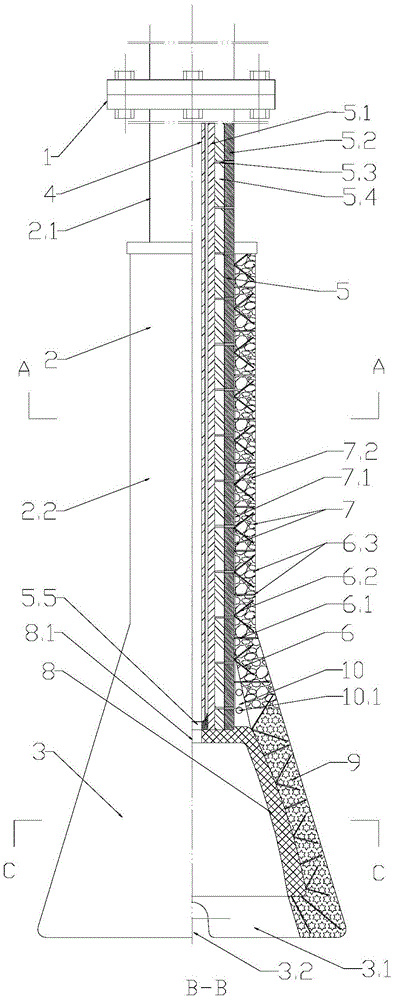

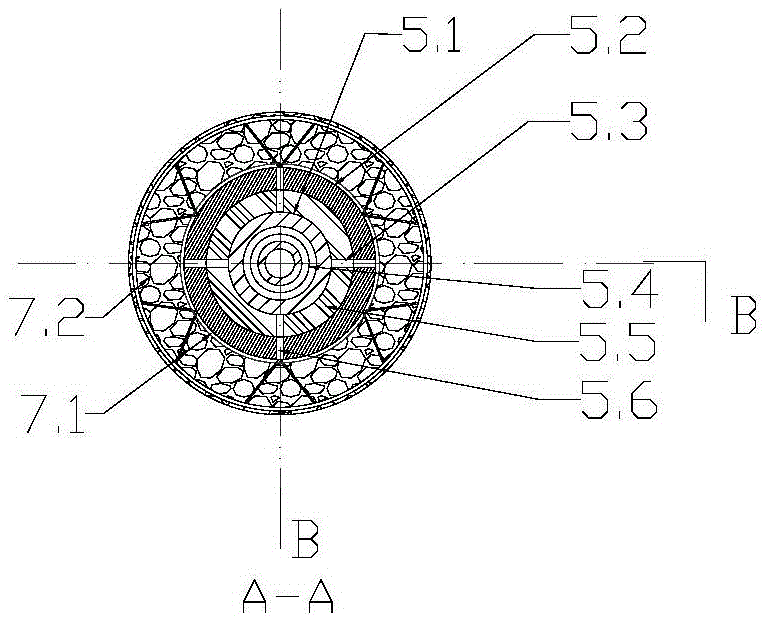

[0055] Such as Figure 1~4 As shown, a molten iron pure spray particle magnesium desulfurization spray gun with a gasification chamber on the gun head includes a connecting flange 1 connected in sequence, a gun barrel 2 and a gun head spraying gasification chamber 3, and the gun barrel 2 is composed of a connecting section gun The tube 2.1 and the gun barrel 2.2 of the gun body section are composed, the connecting section gun barrel 2.1 is composed of the inserted blowing pipe 4 and the gun core 5, and the gun body section gun barrel 2.2 is composed of the inserted blowing tube 4 and the gun core 5, the anchor member group 6 and the refractory casting The lining consists of 7,

[0056] From the inside to the outside of the gun core 5 are the main tube 5.1 and the reinforcing tube 5.2 in sequence. The outer side of the main tube 5.1 takes the axis as the centerline and evenly arranges a plurality of bridge welding parts 5.3 for connecting the reinforcing tube 5.2 in a radial sh...

Embodiment 2

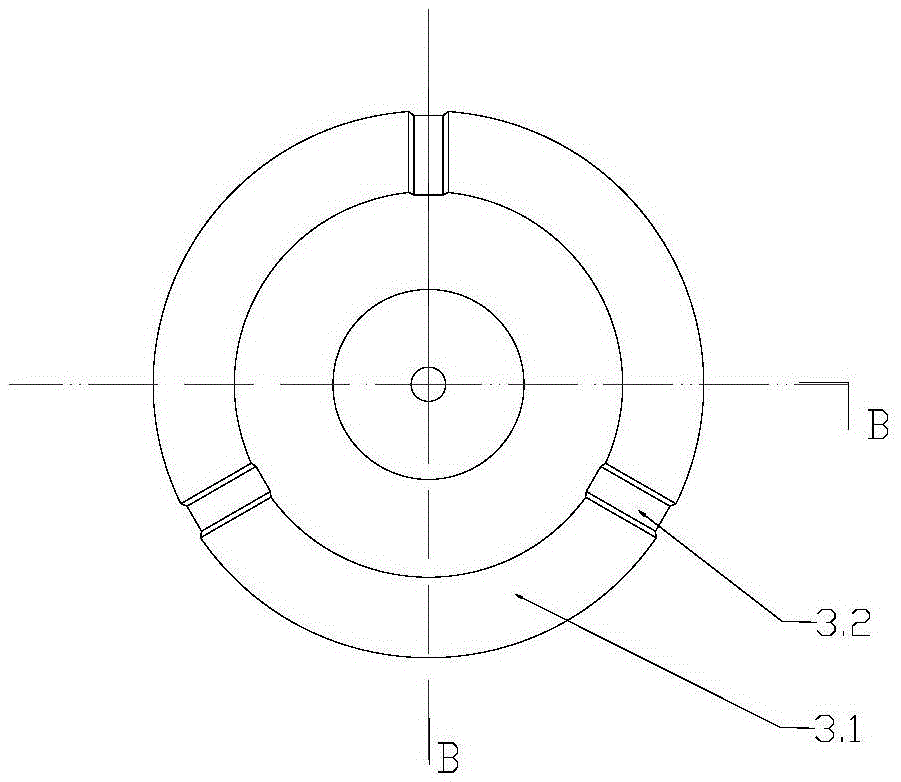

[0075] Such as Figure 5-7 As shown: the structure of the spray gun in this embodiment is basically the same as that of the spray gun in Embodiment 1, the difference is that: the lower end of the gasification chamber bell jar 8 is provided with a bottom skirt 3.1, and the bottom skirt 3.1 is uniformly arranged with 5 rows Gas port 3.2, at the same time, the preparation method of the spray gun is different: the specific difference is in the following steps:

[0076] 3) Select axial and circumferential steel plates, steel bars or steel rods, and stack welding to prepare steel frame reinforced tube 5.2, steel frame reinforced tube 5.2 directly welds bridge weldment 5.3; filling material 5.4 is refractory casting containing carbon material or powdered refractory filler;

[0077] 4) Use longitudinal and circumferential steel plates, steel rods or steel rods of appropriate size, laminated and welded to prepare the side wall frame, select a thick-walled steel plate of appropriate si...

Embodiment 3

[0079] Such as figure 1 , 3 , 8, and 9, the structure of the spray gun in this embodiment is basically the same as the structure of the spray gun in Embodiment 1, the difference is that the cross-section of the spraying gasification chamber 3 of the gun head is elliptical, and the corresponding gasification chamber bell jar 8 1. The annular anchor 6.3 in the gasification chamber area and the bottom skirt 3.1 of the gasification chamber are also elliptical, and two exhaust ports 3.2 are opened symmetrically with the short axis in the direction of the oval long axis bottom skirt 3.1. Between the gun barrel 2.2 and the gasification chamber 3 is a circular to elliptical transition section.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com