Liquid ejecting apparatus and wiping method

一种喷射装置、液体喷射部的技术,应用在印刷等方向,能够解决附着于托架或头主体的侧面上等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

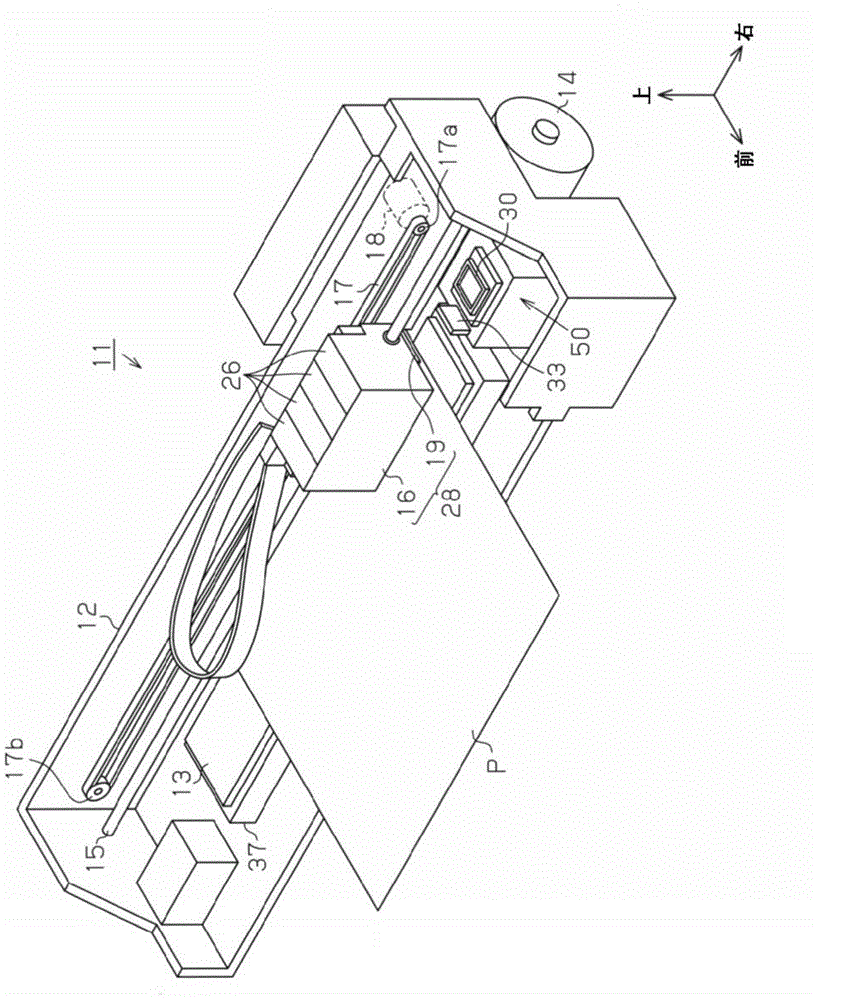

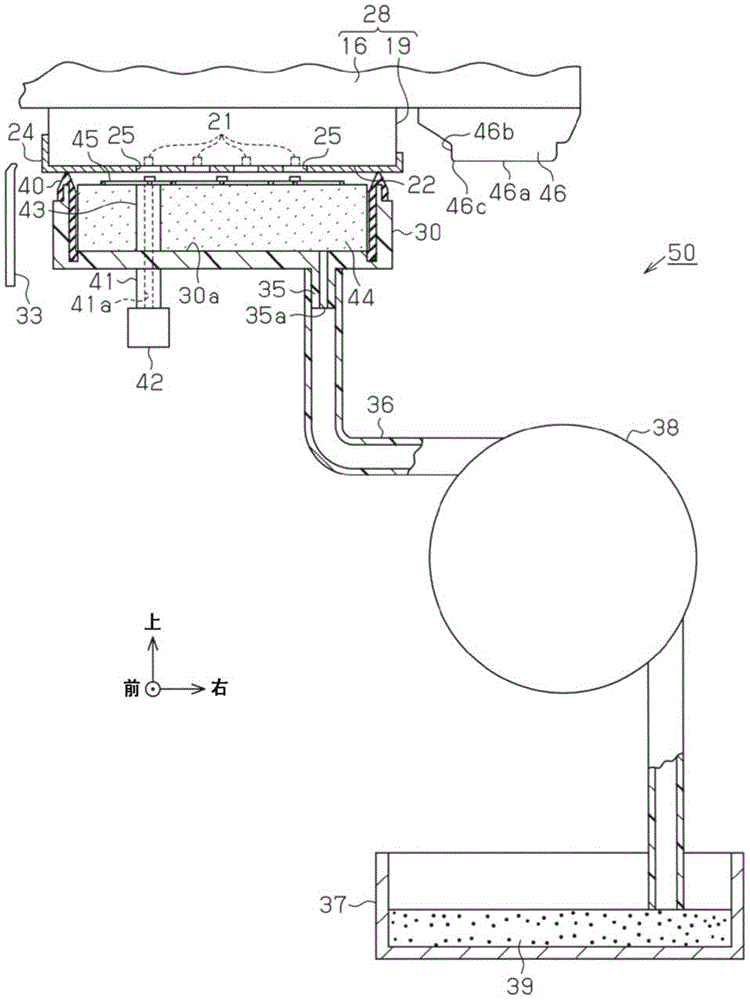

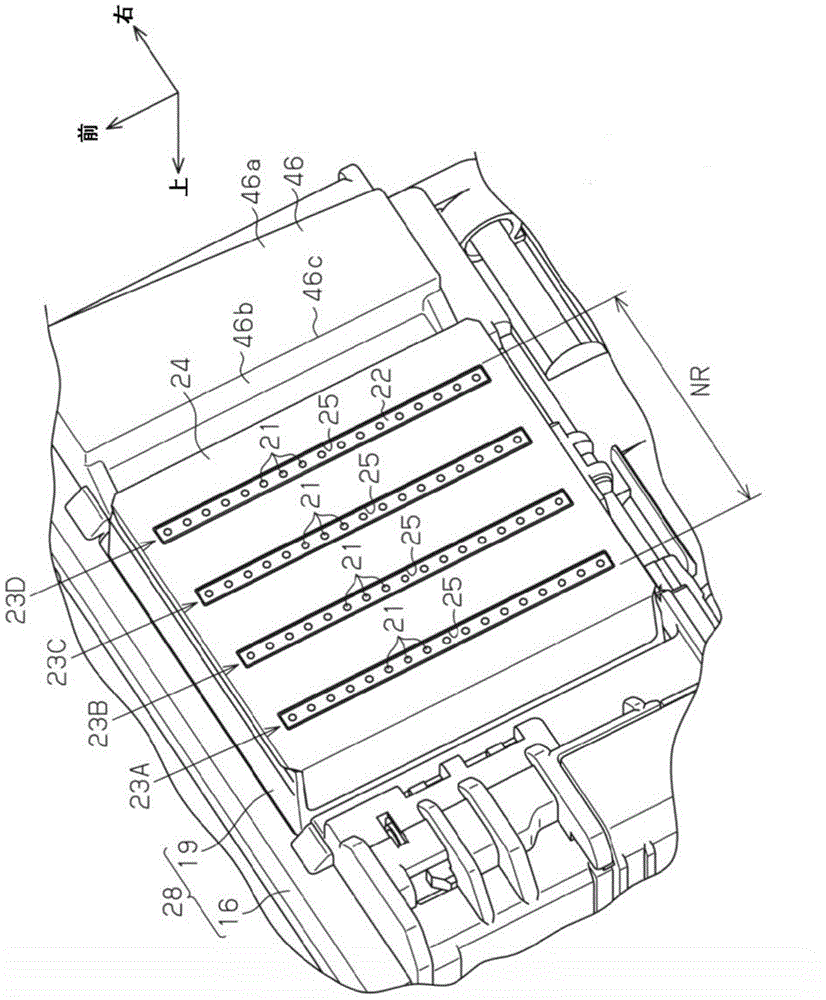

[0031] Hereinafter, an embodiment in which a liquid ejecting device is embodied as an inkjet printer will be described with reference to the drawings.

[0032] Such as figure 1 As shown, an inkjet printer 11 as an example of a liquid ejecting device includes a substantially box-shaped main body casing 12 having a substantially rectangular box shape. In the lower part of the main body casing 12, the support stand 13 is extended along the longitudinal direction, ie, the left-right direction. The paper P is fed from the rear side onto the support table 13 by a paper feeding mechanism not shown, driven by a paper feeding motor 14 provided on the lower rear surface of the main body casing 12 .

[0033]Above the support base 13 in the main body casing 12 , a guide shaft 15 is bridged along the longitudinal direction of the support base 13 , that is, the left-right direction. A carriage 16 is supported on the guide shaft 15 so as to be reciprocable along the guide shaft 15 . A dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com