Segmented tightness testing method

A test method and tightness technology, which is applied in the field of ships, can solve the problems of inconvenient weld tightness testing and achieve the effect of broad market prospects

Active Publication Date: 2015-02-04

ZHEJIANG OCEAN UNIV

View PDF11 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The problem to be solved by the present invention is the inconvenient deficiency of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

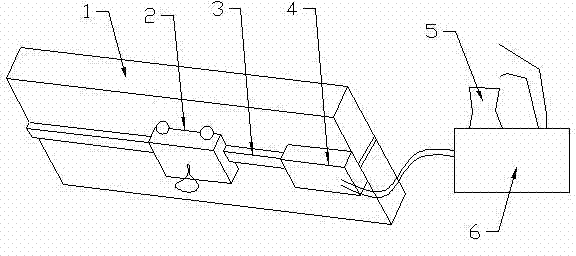

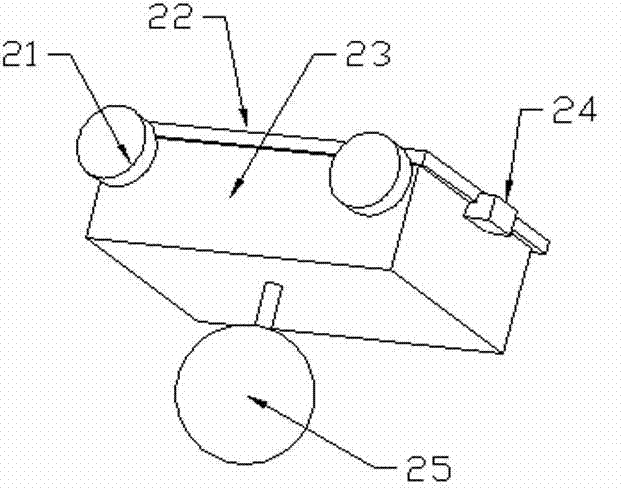

The invention discloses a segmented tightness testing method. A hole to an inner welding seam is drilled on a well-welded segmented outer wall surface; the periphery of the hole is welded with an air testing device for realizing inner air supply; a leakage detection device is arranged on a welding strip for detection a leakage point; the air testing device is connected with an air compressor via an air tube; the air inlet of the air compressor is provided with an atomizer loaded with iodine water, and thus air sucked by the air compressor contains iodine vapor for filling the welding seam with iodine-containing air; the air testing device fills air inside the welding seam, the leakage detection device moves on the welding strip for testing whether air leakage exists; and the leakage detection device is internally provided with starch water, in case of air leakage, a color is changed as the air contains iodine, and the detection effects are obvious.

Description

technical field [0001] The invention relates to a segmented tightness test method, in particular to a welded seam tightness test used for the segmental exterior in contact with seawater, and belongs to the technical field of ships. Background technique [0002] The water injection inspection of the ship is to press the water to the specified height according to the requirements of the specifications according to different parts, so that the hull structure and welds are in a certain state of pressure, and then check the leakage of the welds. But this method has following limitation in use: (1) must install water supply and drainage system, the waste of time and manpower is very big, when particularly testing the larger cabin of volume; (3) After the test, the ship and the berth were wet and dirty. After the test, the scaffolding and ladders in the cabin were wet and slippery, and the construction and repair work in the cabin before drying was inconvenient; (4) When the diffe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/20

Inventor 谢永和

Owner ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com