Polyhydroxy lignin/silicon dioxide composite nano particle and preparation method thereof

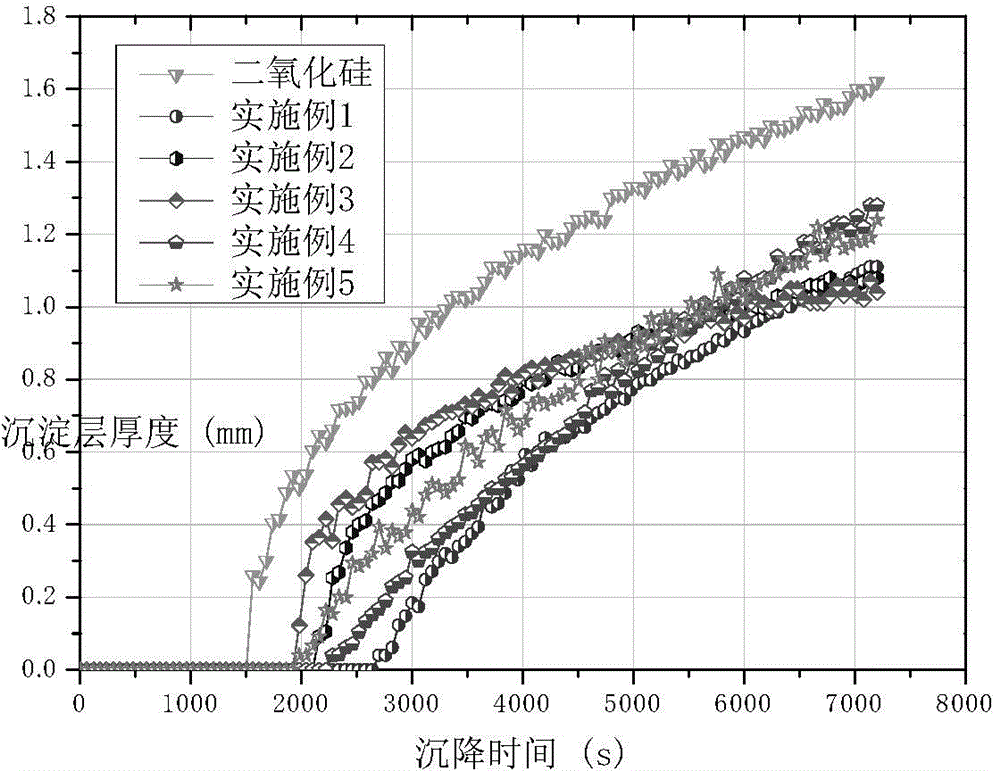

A technology of composite nanoparticles and silica, which is applied in the field of polyhydroxylignin/silica composite nanoparticles and its preparation, can solve uneven dispersion, serious agglomeration of polyhydroxylignin/silica composite particles, and toxicity Organic solvents and other problems, to achieve the effect of simple process, excellent performance-price ratio and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention relates to a kind of preparation method of polyhydroxy lignin / silicon dioxide composite nano material, and this method comprises the following steps:

[0032] (1) adding industrial lignin to water to achieve a mass percentage concentration of industrial lignin based on the total mass of the industrial lignin aqueous solution is 10-40%, then adjusting the pH of the solution to 8-12; adding polyols and catalysts, heating At 70-90°C, dropwise add epoxy haloalkane, and at the same time add dropwise alkaline regulator to maintain the pH of the reaction solution at 8-12, and carry out the reaction for 2-4 hours to obtain a polyhydroxy lignin solution;

[0033] Industrial lignin mainly comes from the cooking wastewater of the paper pulping industry. According to different raw materials, pulping process and extraction methods, their physical and chemical properties vary greatly. Industrial lignin is usually divided into four categories: ①Hydrolyzed lignin: ...

Embodiment 1

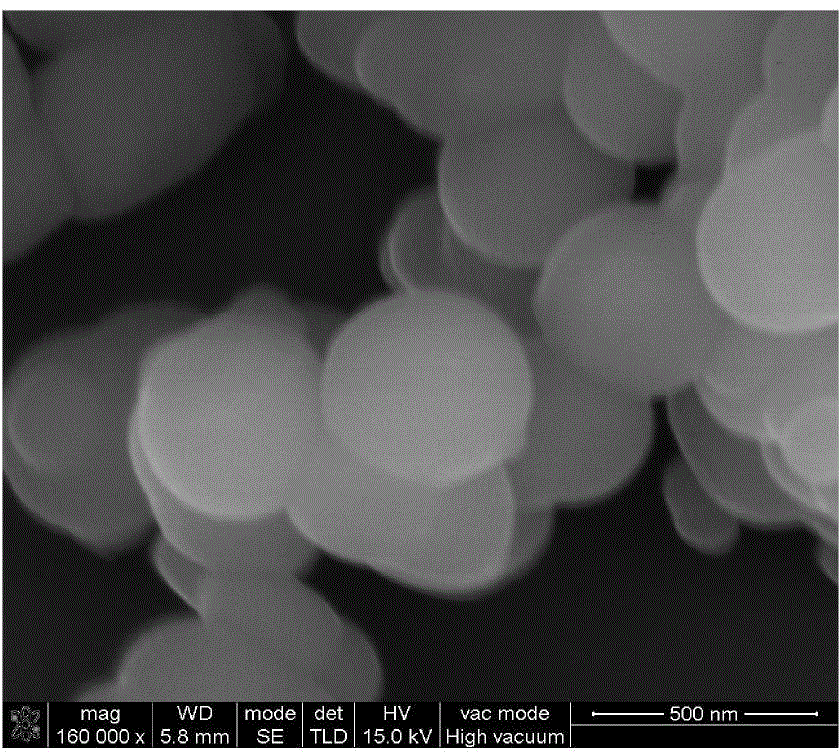

[0061] Add 100g of wood pulp alkali lignin into water to reach a mass percentage concentration of wood pulp alkali lignin based on the total mass of the wood pulp alkali lignin aqueous solution to be 10%, then adjust the pH of the solution to 8, add 10g of pentaerythritol and 0.5g Potassium iodide, warming up to 70°C, adding dropwise 5g of epibromohydrin, and simultaneously adding dropwise a sodium hydroxide solution with a mass percentage concentration of 20% to maintain the pH of the reaction solution at 8, and react for 2 hours to obtain a polyhydroxy lignin solution; Prepare a sodium silicate aqueous solution with a mass concentration of 1%, and add the polyhydroxylignin solution obtained above to it, mix it uniformly, adjust the pH to 7 with ammonium chloride, heat to 40°C, react for 2 hours, and then use 20 Adjust the pH to 3.0 with % sulfuric acid, continue to react for 0.5 hours, age for 1 hour, centrifuge and precipitate, and dry to obtain a powdery product, which is t...

Embodiment 2

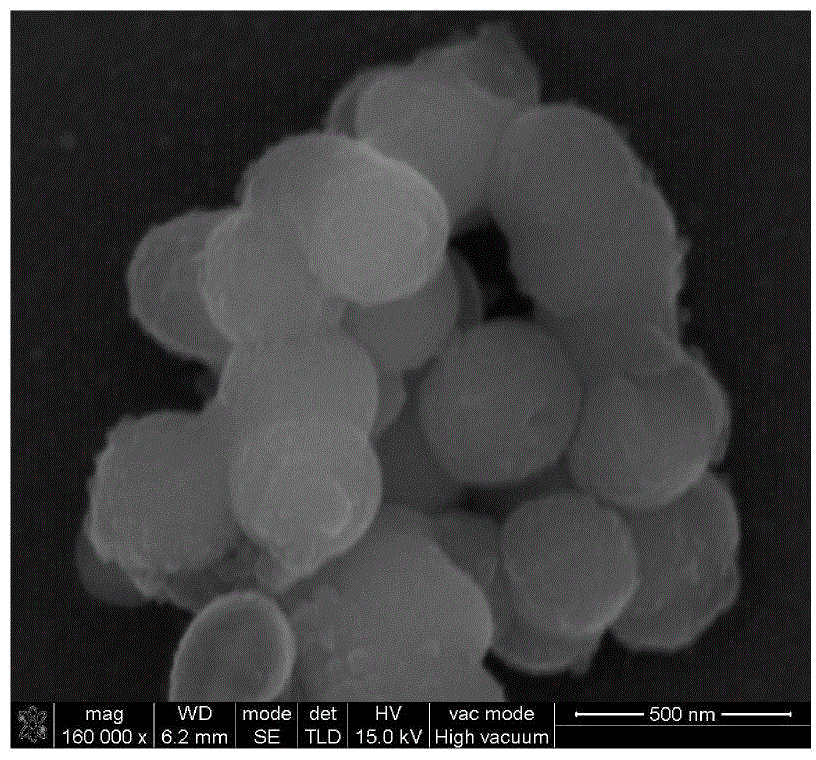

[0063]Add 50g of wood pulp alkali lignin and 50g of bamboo pulp alkali lignin into water to achieve a mass percentage concentration of alkali lignin based on the total mass of the mixed alkali lignin aqueous solution to be 40%, then adjust the pH of the solution to 12, and add 50g Glycerol and 2g of aluminum oxide are heated up to 90°C, and 30g of epichlorohydrin is added dropwise, and at the same time, a potassium hydroxide solution with a concentration of 30% by mass is added dropwise to maintain the pH of the reaction solution at 12, and react for 4 hours to obtain polyhydroxy lignin lignin solution; prepare a sodium silicate aqueous solution with a mass concentration of 10%, and add the polyhydroxy lignin solution obtained above to it, mix it uniformly, adjust the pH to 9 with ammonium chloride, heat to 80° C., and react for 6 hours. Then adjust the pH to 5 with 20% nitric acid, continue to react for 2 hours, age for 3 hours, centrifuge and precipitate, and dry to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com