Mixing and pouring device applicable to medical and chemical materials

A technology of chemical raw materials and dumping devices, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., which can solve the problem that chemical raw materials cannot be fully stirred, the structure of the stirring rod is simple, and the dumping device is not included, etc. problems, to achieve the effect of simple structure, convenient operation, and protection of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] A clear and complete description will be made below in conjunction with the accompanying drawings to the mixing and discharging device suitable for pharmaceutical and chemical raw materials of the present invention.

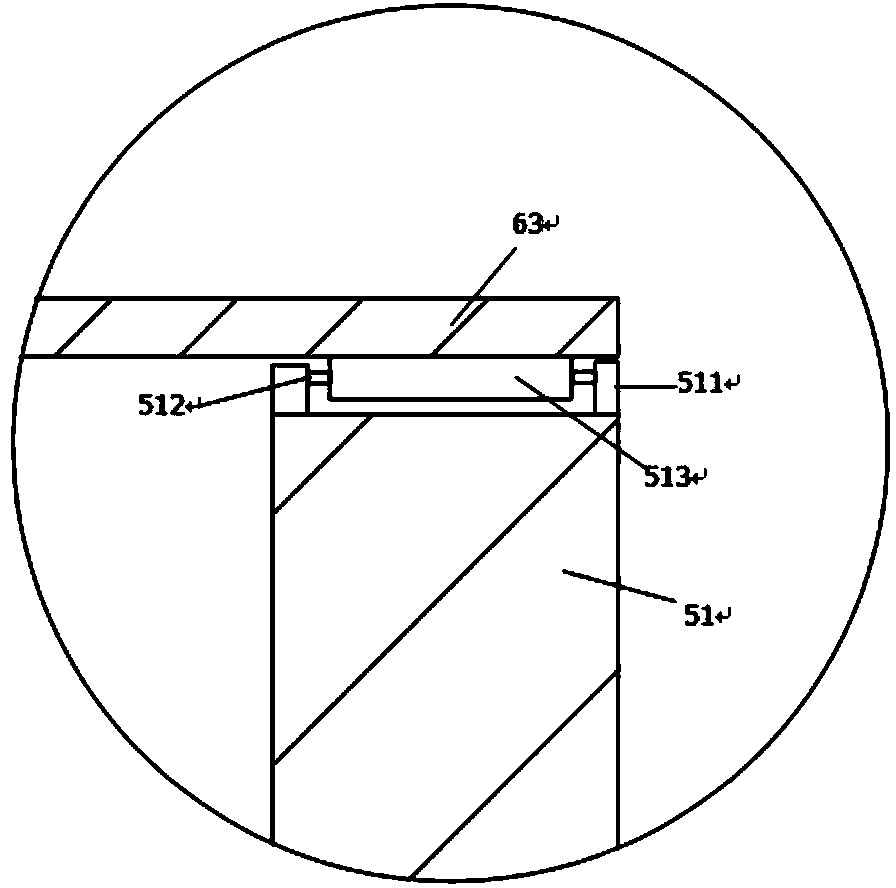

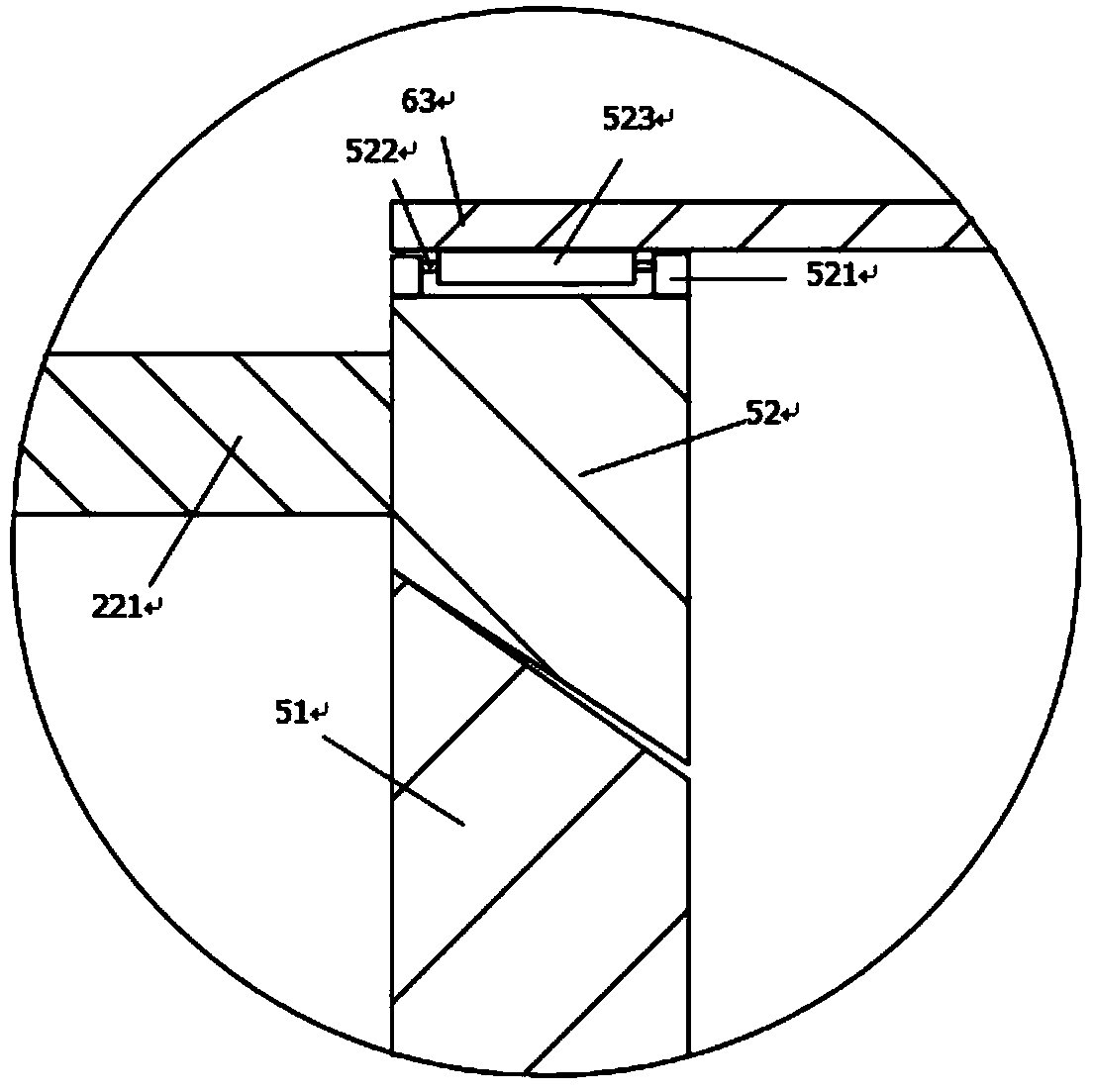

[0023] Such as Figure 1 to Figure 3 As shown, the present invention is applicable to the mixing and unloading device of medicine and chemical raw materials, including a base 1, a support 2 arranged on the base 1, a first cylinder 3 arranged on the support 2, a cylinder 3 arranged above the base 1 Support structure 4, a rectangular block 8 on the left side of the support structure 4, a frame body 5 above the support structure 4, a stirring structure 6 accommodated in the frame body 5, and a right side of the frame body 5 The tensile structure 7 and the receiving box 9 located above the rectangular block 8 .

[0024] Such as Figure 1 to Figure 3 As shown, the base 1 is in the shape of a cuboid. The bracket 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com