Tunnel steel arch installation machine and its installation method

A steel arch and installation machine technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of increasing equipment entry and departure time, difficult to popularize, and complicated maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

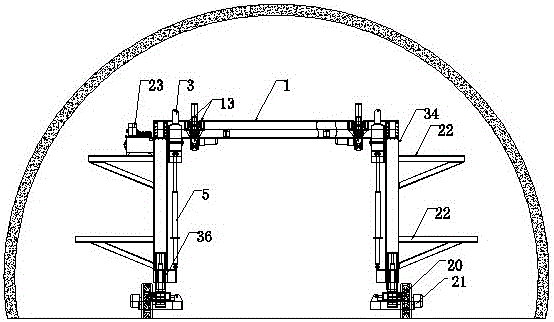

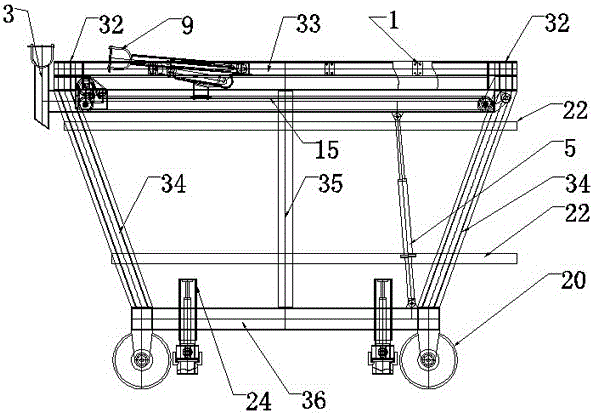

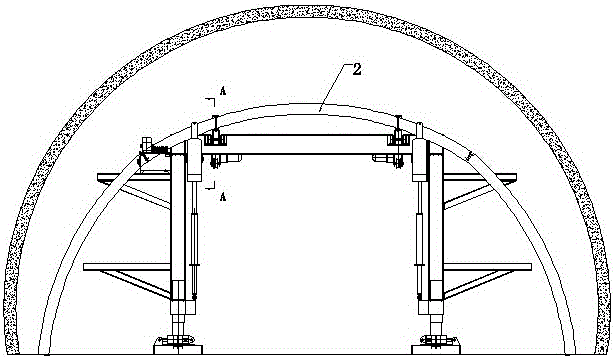

[0049] A tunnel steel arch installation machine, comprising a frame, a walking drive mechanism, a lifting mechanism, a traction mechanism and a manipulator mechanism, a platform 1 is set on the top of the frame, the manipulator mechanism is set on the platform 1, and the traction mechanism is set on the frame The upper drives the manipulator mechanism to move on the platform 1, and the walking drive mechanism is set at the bottom of the frame to drive the frame to move, and the lifting mechanism is movably connected to the frame; when the lifting mechanism is working, it moves to the ground to install the connected steel arch The frame 2 is lifted to the platform 1, the manipulator mechanism removes the steel arch frame 1 from the lifting mechanism, the traction mechanism drives the manipulator mechanism to move the steel arch frame 2 to the installation position, and the steel arch frame 2 is lifted by the manipulator mechanism Raised to installation height.

[0050] There ar...

Embodiment 2

[0062] A method for installing a steel arch with a tunnel steel arch installation machine, comprising: first driving the installation machine to a working position through a traveling drive mechanism, then moving a lifting mechanism to the ground to lift the installed and connected steel arch to a platform, The manipulator mechanism removes the steel arch frame from the lifting mechanism, drives the manipulator mechanism to move the steel arch frame to the installation position through the traction mechanism, lifts the steel arch frame to the installation height through the manipulator mechanism, and manually adjusts the side arch swing angle to the side. Turn the arch foot to the position, tighten the connecting bolts of the steel arch frame, weld the steel arch frame to the pre-set anchor rod, and loosen the jaws of the manipulator.

[0063] The installation method of the present invention is described further below:

[0064]First drive the installation machine to the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com