Steel reinforced concrete column-steel reinforced concrete inclined beam T-shaped joint

A technology of concrete columns and concrete beams, which is applied in the direction of architecture and building construction, can solve the problems of high cost, complicated process, poor fire resistance and corrosion resistance, etc., and achieve the effect of strengthening the node area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

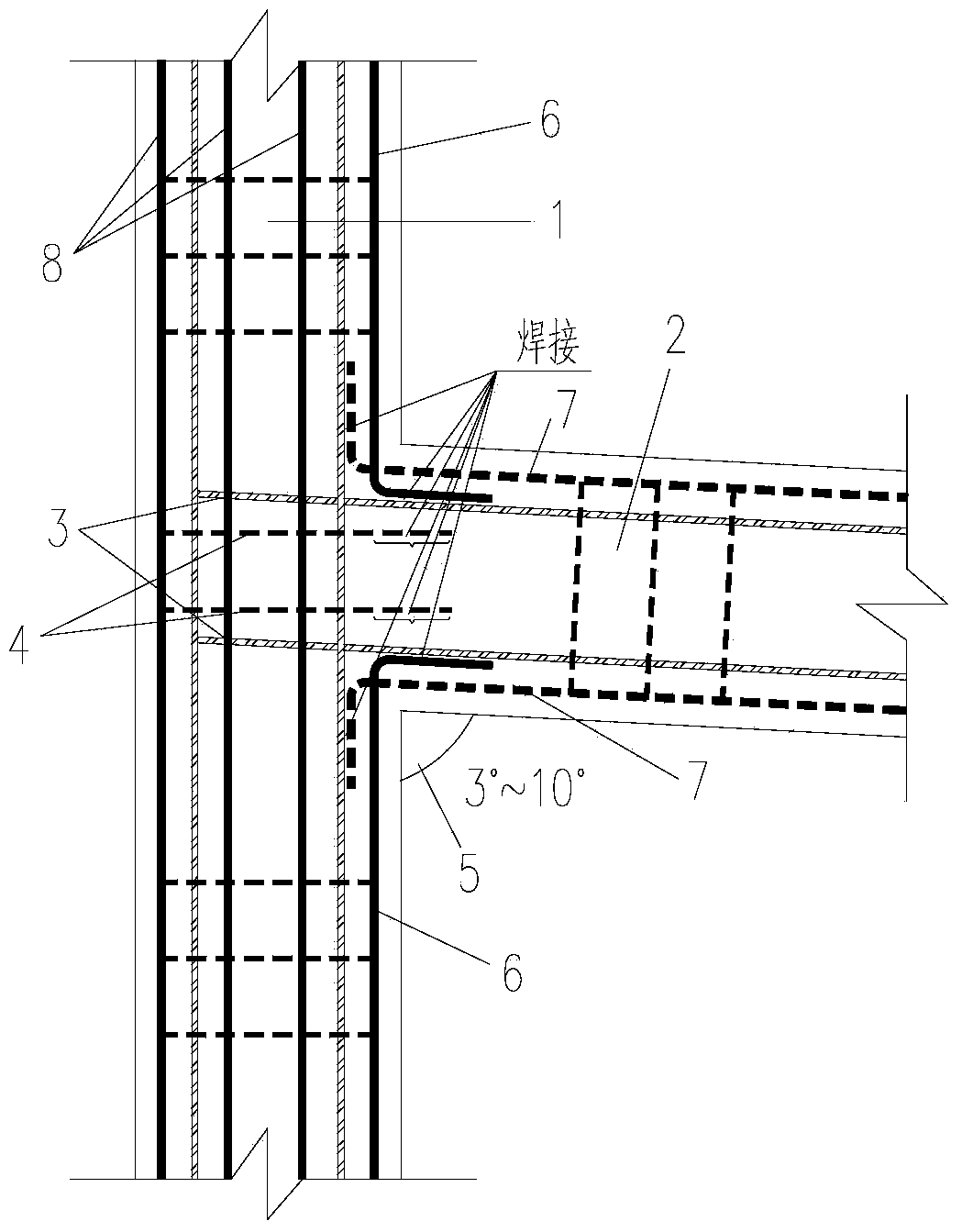

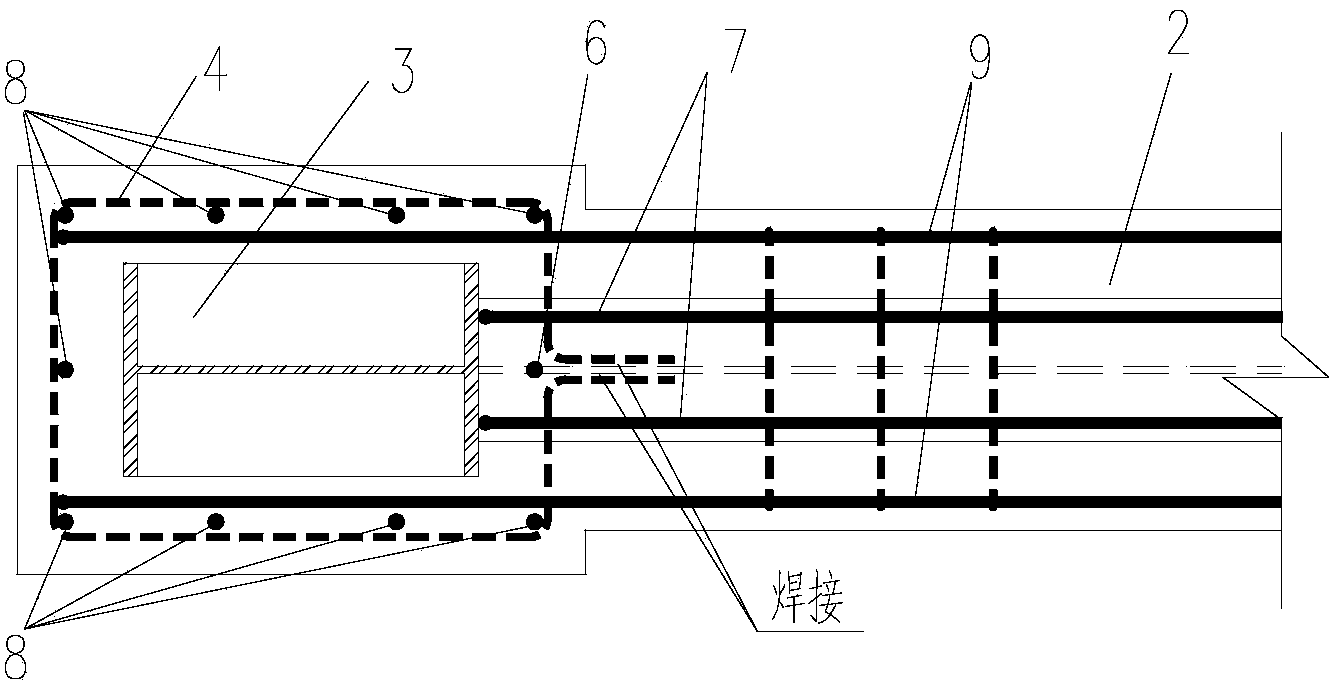

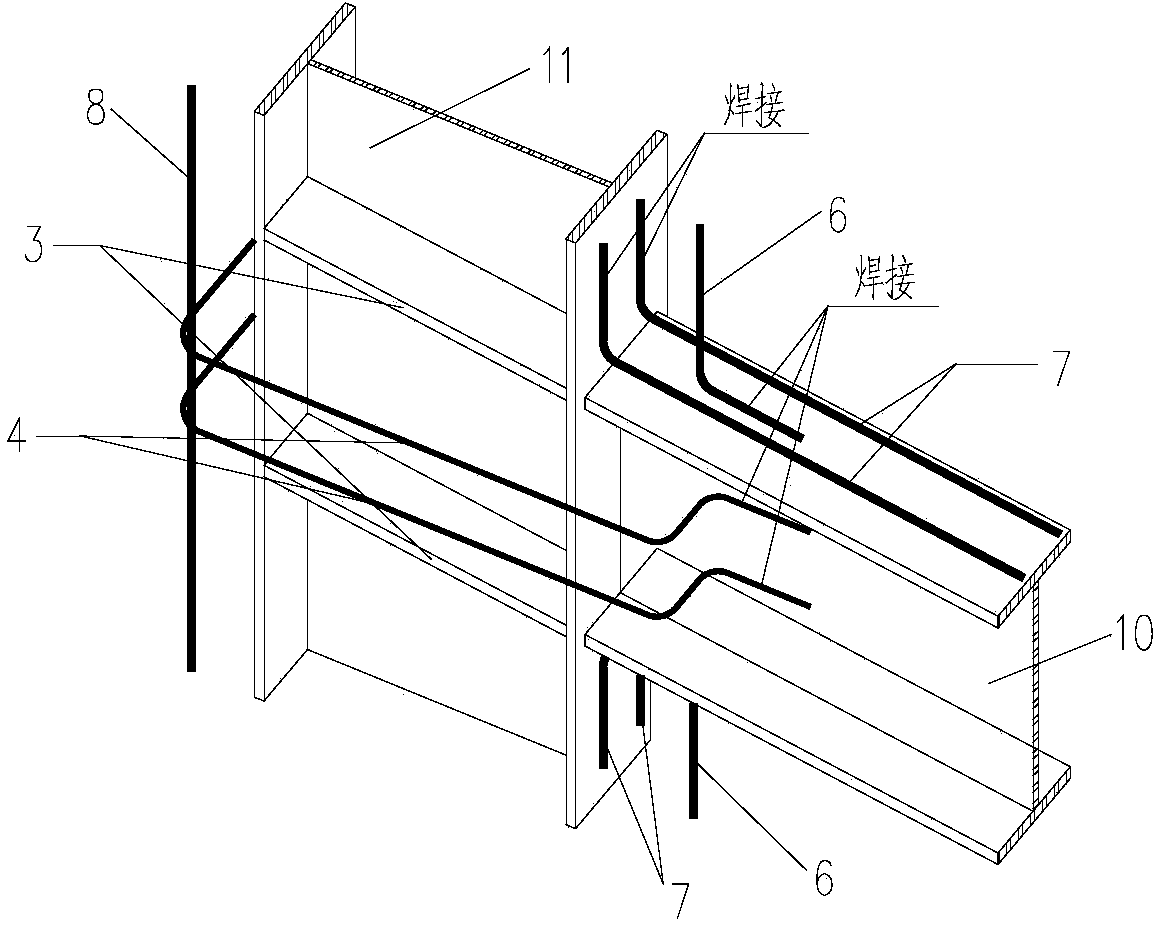

[0027] Following the above-mentioned technical scheme of the present invention, this embodiment provides a steel concrete column-steel concrete oblique beam T-shaped joint, the structure of which is shown in Figure 1 ~ Figure 3 , the node is formed by the solid connection (welding) of steel concrete column 1 and steel concrete beam 2; said steel concrete beam 1 is provided with H-shaped steel 10 in the beam, and said steel concrete column 2 is provided with H-shaped steel 11 in the column ;in:

[0028] Along the upper and lower flanges of the H-shaped steel 10 in the beam, one or more longitudinal ribs 7 in the beam need to pass through the flange of the medium-shaped steel in the column, and one end thereof is bent when reaching the flange of the medium-shaped steel 11 in the column. It is flush with the flange of the column-medium steel 11, and fixed (welded) on the flange of the column-medium-shaped steel 11; in the steel-reinforced concrete beam 1, one or more horizontal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com