Semi-automatic catcher

A feeder, semi-automatic technology, applied in electrical components, electrical components and other directions, can solve the problems of inconvenient operation, short service life, affecting production efficiency, etc., to simplify the work process, long service life, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

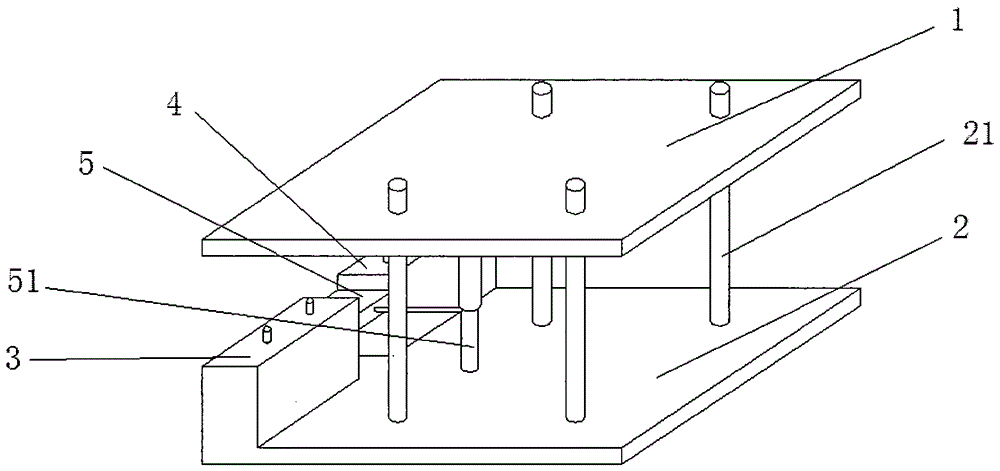

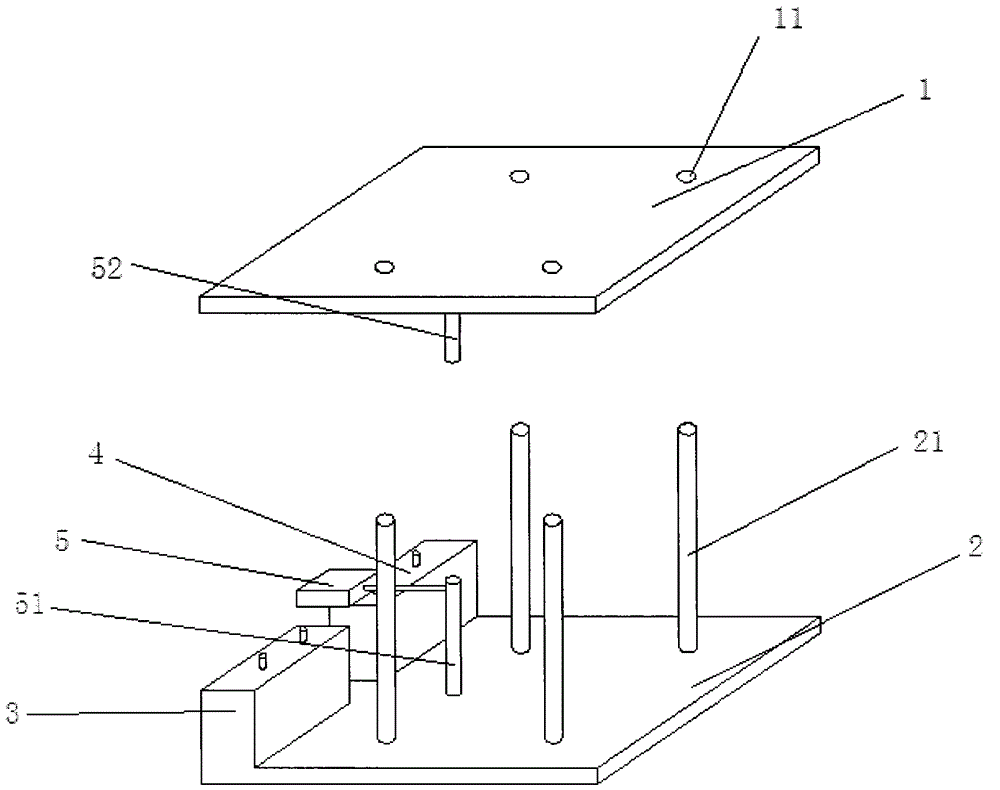

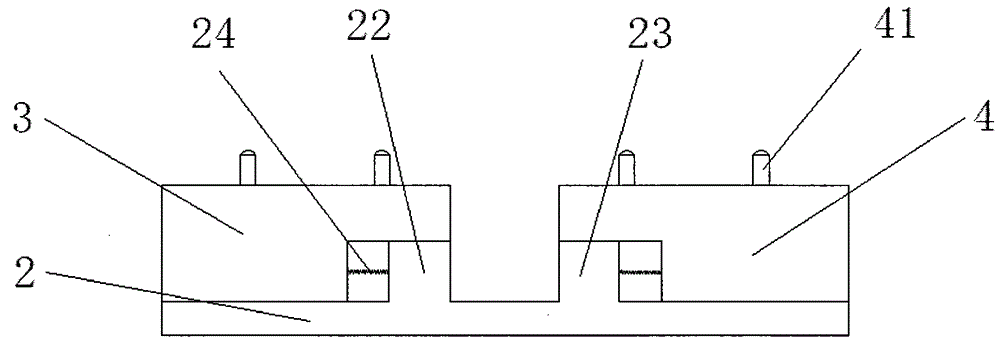

[0039] see figure 1 and figure 2 , the present invention relates to a semi-automatic material receiver, comprising a feeding board 1 and a lowering board 2, a plurality of vertical guide rails 21 are fixedly connected to the lowering board, and correspondingly provided with The through holes 11 that the guide rails match, each of the guide rails is sleeved with a return spring, and the return spring is located between the upper material plate and the lower material plate, and the lower side of the upper material plate There is an accommodating cavity for placing metal buckles on the top, the accommodating cavity is located at the front of the feeding plate, and a chute is provided on the lower side of the feeding plate, and the chute is connected with the The accommodating cavity is connected, and the upper side of the blanking plate is provided with a supporting block corresponding to the accommodating cavity for fixing the material belt.

[0040] The setting of the loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com