A mechanical drafting device for an air-jet loom

A technology of drafting device and air-jet loom, which is applied to looms, textiles, textiles and papermaking, etc., can solve the problems of wasting air, large drafting air pressure, and increased costs, so as to improve quality, enhance variety adaptability, Avoid the effect of weft shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

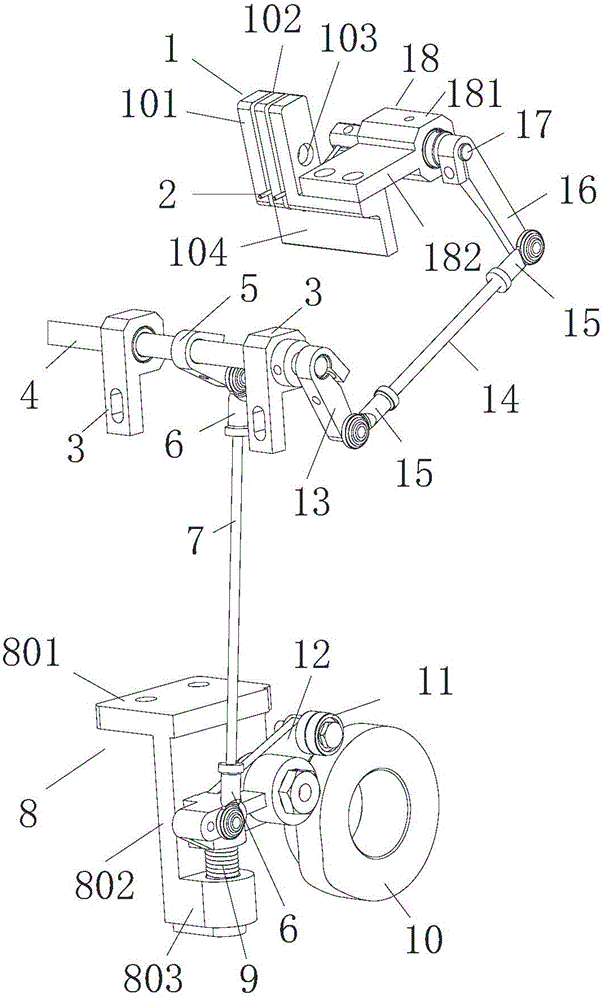

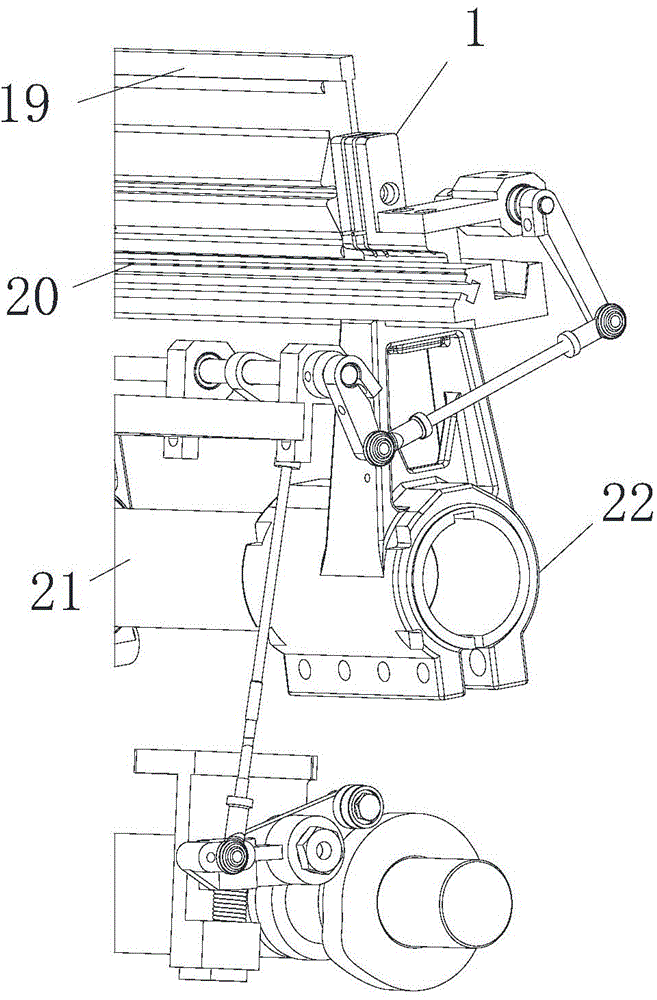

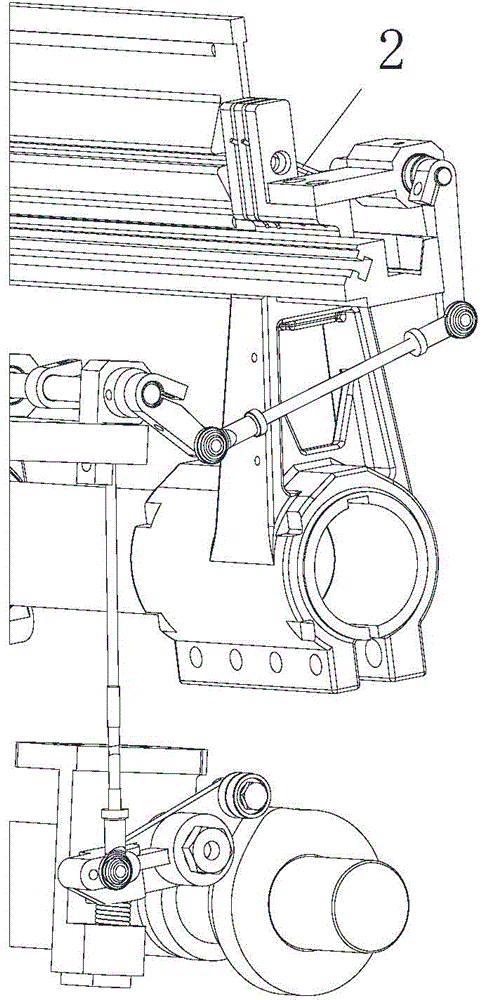

[0023] Such as figure 1 and image 3 Shown, a kind of air-jet loom mechanical drafting device comprises a loom frame, and a weft beating mechanism, a yarn clamping mechanism and a driving mechanism are arranged on the loom frame; the weft beating mechanism includes a beating shaft 21, a beating arm 22. The sley 20 and the steel reed 19, the beat-up arm 22 swings under the drive of the beat-up shaft 21, the sley 20 is fixed above the beat-up arm 22, and the steel reed 19 is arranged above the sley 20; The yarn gripping mechanism includes a yarn gripper 1 and a swing lever 2. The yarn gripper 1 includes a yarn gripper 104 and a plurality of yarn grippers 101 arranged on the yarn gripper 104 and arranged in sequence. The yarn gripper 104 is arranged on the sley 20, each yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com