Preparation method of fiber composite material for signal cables and product thereof

A fiber composite material and cable technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc., can solve the problems of signal transmission distortion, poor anti-noise ability of cotton yarn, performance discount of electronic products, etc. Tensile strength, improve the effect of noise resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: This embodiment provides a method for preparing a fiber composite material for signal cables, which includes the following steps:

[0030] (1) prepare polyvinyl chloride resin PVC fiber;

[0031] (2) prepare flax fiber; and soak the prepared flax mixed fiber in 2% sodium hydroxide solution for 1 to 2 hours, after cleaning with clear water, carry out acid bath dealkalization, and then clean with deionized water until it becomes medium Finally, put it in a baking oven and bake it for 0.5-1 hour at 100-120°C for later use;

[0032] (3) prepare fixative;

[0033] (4) take the PVC fiber prepared by step (1) as the base film, by the fixed solution prepared by step (3), the flax fiber prepared by step (2) is fixed on the polyvinyl chloride resin PVC fiber, place In a baking oven, under the condition of 100-120° C., bake for 0.5-1 hour, and cool naturally to obtain a fiber composite material for signal cables.

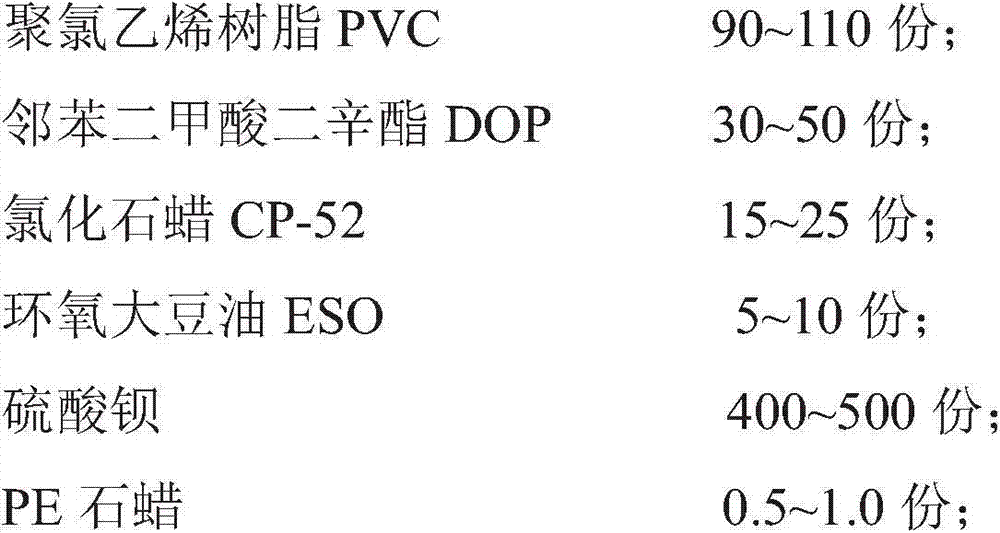

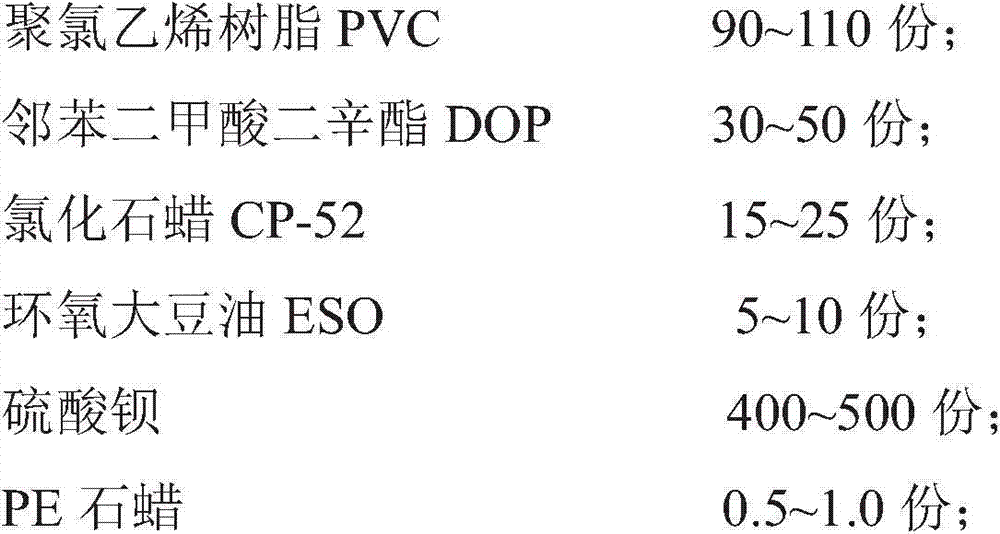

[0034] Described step (1) comprises the following...

Embodiment 2

[0051] Example 2: This example provides a method for preparing a fiber composite material for signal cables, and a product prepared by this method. The steps and components are basically the same as those in Example 1, except that:

[0052] A method for preparing a fiber composite material for a signal cable, comprising the following steps:

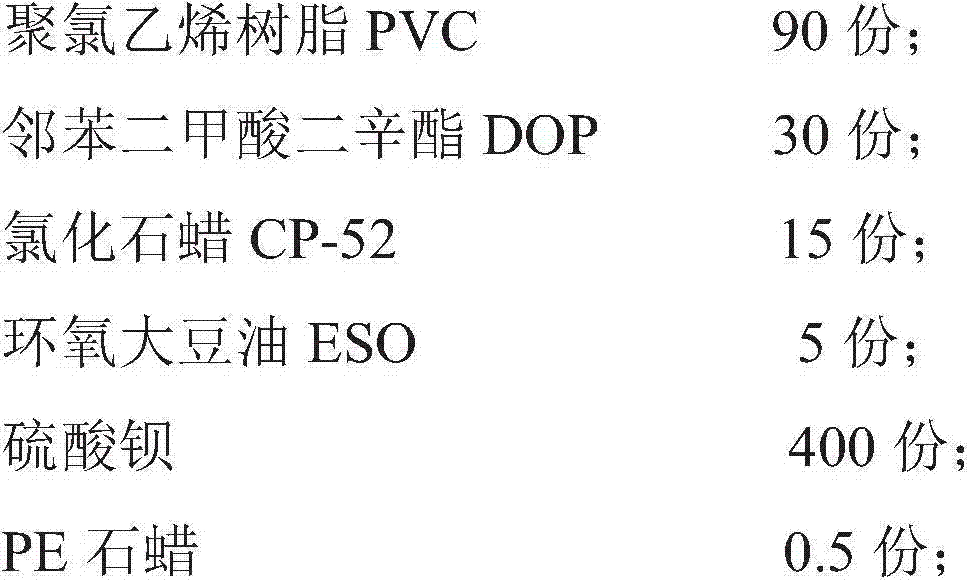

[0053] (1) prepare polyvinyl chloride resin PVC fiber;

[0054] (2) Prepare flax fiber; and soak the prepared flax mixed fiber in 2% sodium hydroxide solution for 1h, after cleaning with clear water, carry out acid bath dealkalization, then clean with deionized water until it is neutral, Finally, put it in a baking oven, and bake it for 0.5h at 100°C for later use;

[0055] (3) prepare fixative;

[0056] (4) take the PVC fiber prepared by step (1) as the base film, by the fixed solution prepared by step (3), the flax fiber prepared by step (2) is fixed on the polyvinyl chloride resin PVC fiber, place Baking in a baking oven at 105° C. ...

Embodiment 3

[0074] Example 3: This example provides a method for preparing a fiber composite material for signal cables, and a product prepared by this method. The steps and components are basically the same as those in Examples 1 and 2, except that:

[0075] A method for preparing a fiber composite material for a signal cable, comprising the following steps:

[0076] (1) prepare polyvinyl chloride resin PVC fiber;

[0077] (2) Prepare flax fiber; and soak the prepared flax mixed fiber in 2% sodium hydroxide solution for 2h, after cleaning with clear water, carry out acid bath dealkalization, then clean with deionized water until it is neutral, Finally, put it in a baking oven, and bake it for 0.8h at 120°C for later use;

[0078] (3) prepare fixative;

[0079] (4) take the PVC fiber prepared by step (1) as the base film, by the fixed solution prepared by step (3), the flax fiber prepared by step (2) is fixed on the polyvinyl chloride resin PVC fiber, place Baking in a baking oven at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com