Blanking taking and placing mechanism

A technology of retrieving mechanism and connecting mechanism, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as inaccurate product positioning, inaccurate product calibration, position deviation and dislocation when picking and placing, and achieve the time of holding pressure The effect of minimizing, avoiding small size and maximizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

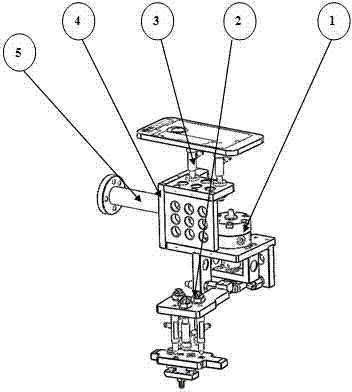

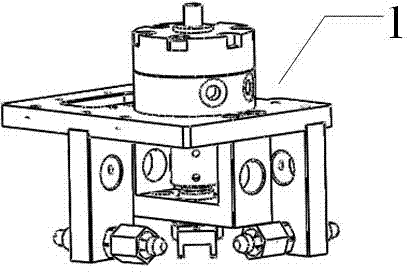

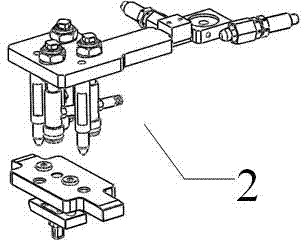

[0014] The loading and unloading mechanism includes a rotating swing arm mechanism 1, a pressure-holding head swing arm mechanism 2, a material retrieving mechanism 3, a cavity connection mechanism 4, and a fixed column 5. It is characterized in that the rotation swing arm mechanism 1 is arranged on the cavity connection mechanism 4, the holding head swing arm mechanism 2 and the material retrieving mechanism 3 are respectively arranged on both sides of the cavity connection mechanism 4 symmetrically, the cavity connection mechanism 4 is fixed by the fixed column 5, and the top of the rotating swing arm mechanism 1 is a rotating part. Below is the swing arm part. The cavity connection mechanism 4 is a semi-frame structure. The fixing column 5 is arranged on the horizontal side of the cavity connection mechanism 4 . A workpiece fixture is arranged above the material taking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com