Novel compaction platform

A vibrating table, a new type of technology, applied in the direction of molding table, molding machine, casting molding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

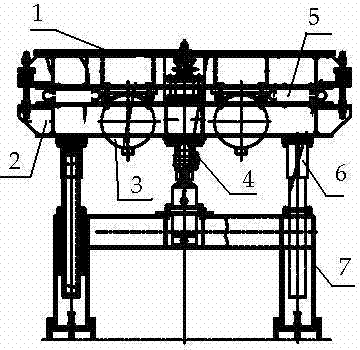

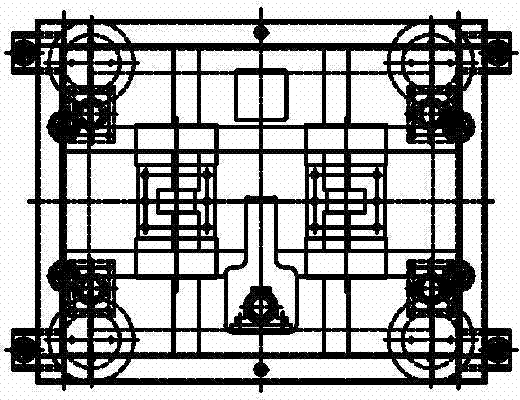

[0011] see figure 1 and figure 2 As shown, the present invention includes a body 7, a vibrating platform 1, a lifting platform 2 and a guide rod 6. The vibrating platform 1 is arranged on the top of the body 7, and a lifting platform 2 is provided below the vibrating platform 1. The lifting platform 2 is supported by the guide rods 6 , an air spring 5 and a vibrating motor 3 are respectively arranged between the lifting platform 2 and the vibrating table 1 , and a hydraulic cylinder 4 is arranged between the guiding rods 6 . The working principle is: when the formwork and the sand box are transported to the bottom of the sand warehouse through the roller table and sand needs to be added, the hydraulic cylinder 4 will lift the lifting table 2 until the vibration table 1 lifts the formwork and the sand box. At this time, the formwork and sand The box has been separated from the roller surface and is directly below the sand adding device. The air spring 5 lifts the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com