Tension control method and device

A technology of tension control and tension, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of large cycle tension error, lower cloth grade, uneven gap, etc., and achieve constant tension and maintain the effect of weft yarn gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

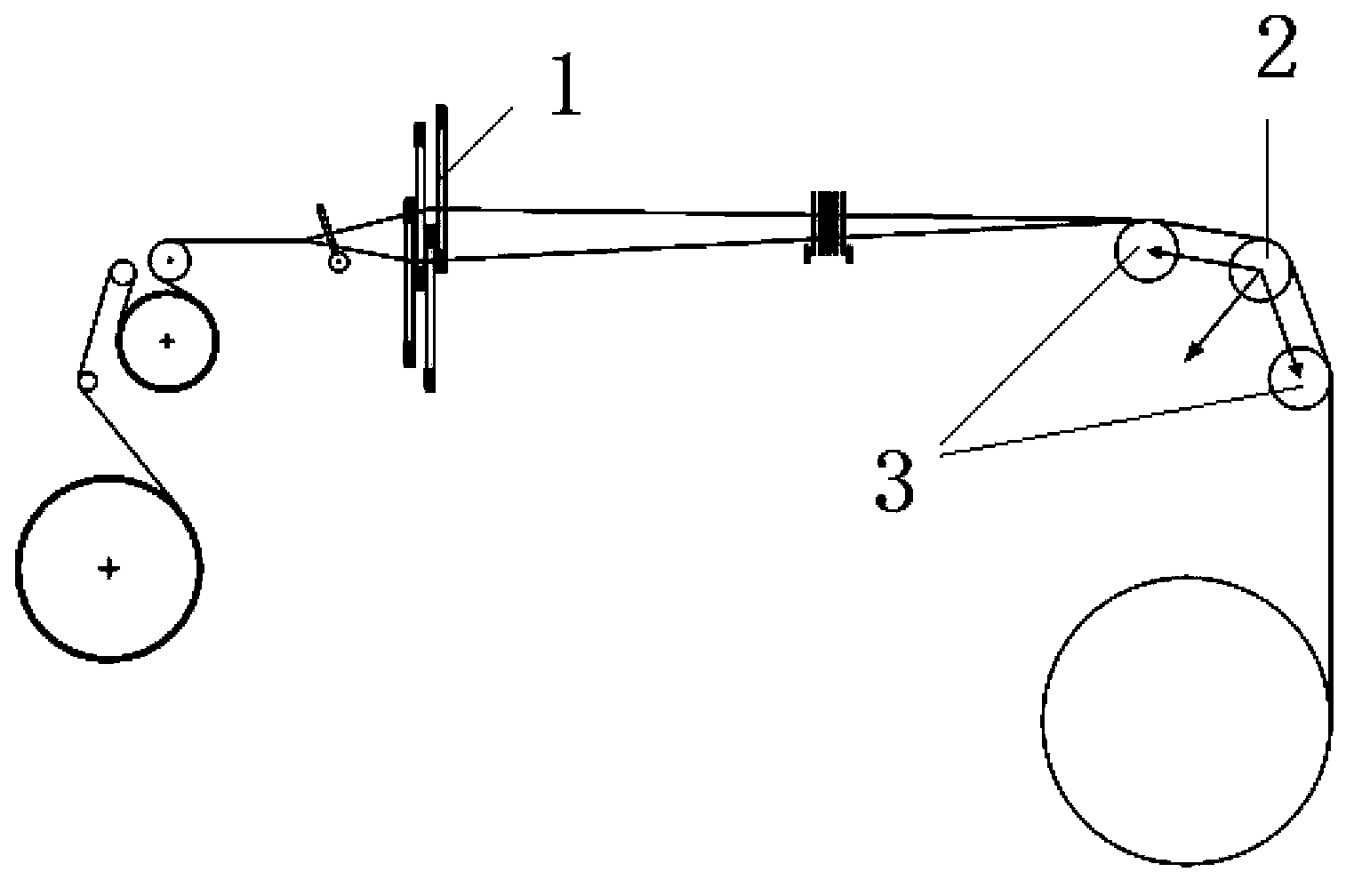

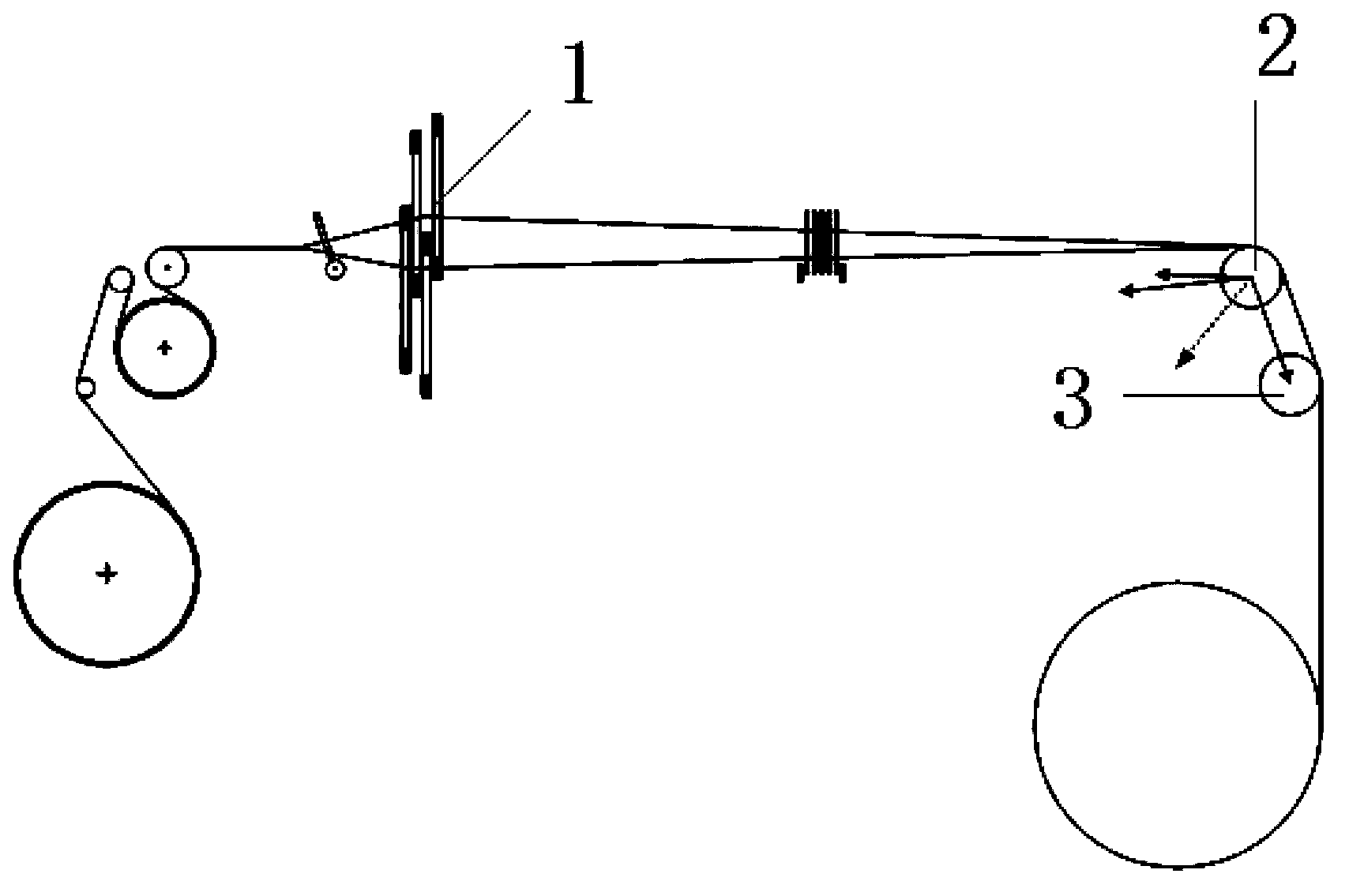

[0014] According to the tension control method of the present invention, according to the specific value of warp yarn tension accurately collected in the movement interference of heald frame, beating-up, warp stopper vibration and loom vibration during the operation of the loom, the collected value is passed through a data processing algorithm Calculate the real warp tension value, control the speed and position of the let-off motor according to the change of the real warp tension, and precisely control the warp tension through the tension control device to keep it constant.

[0015] The struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com