Double-layer waste gas collection hood

A waste gas collection, double-layer technology, applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problem of poor suction in the edge area of the waste gas collection cover, and achieve good waste gas collection effect and uniform suction distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

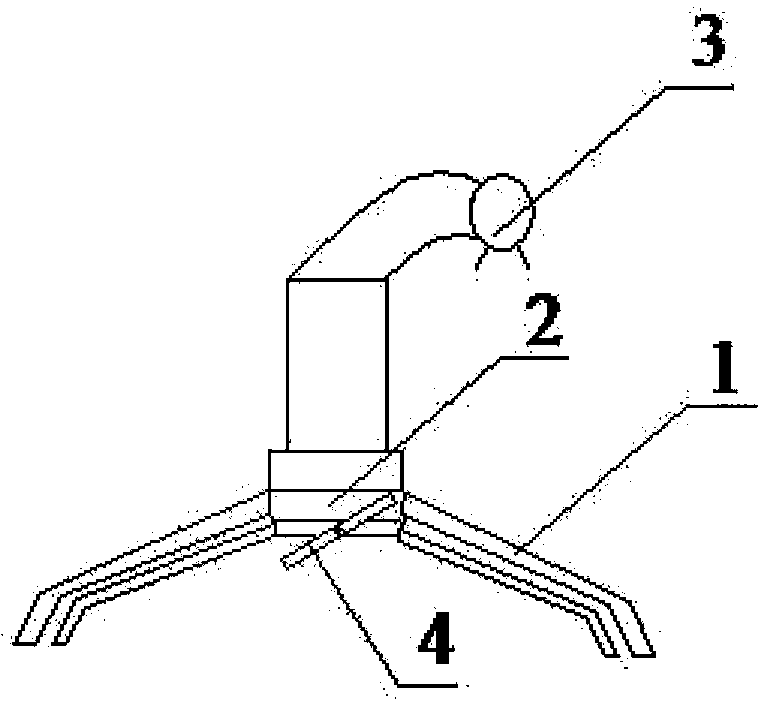

[0012] A double-layer exhaust gas collection cover, comprising a cover body 1 and an air introduction port 2 at the center of the cover body 1, the air introduction port 2 is externally connected with an induced fan 3, and the cover body 1 has a double-layer structure with two inner and outer layers.

[0013] Further, the cross section of the cover body 1 is made into a circle.

[0014] Further, a regulating valve 4 is provided at the central air inlet 2 of the cover body 1 .

[0015] The working process of the double-layer exhaust gas collection cover is: when the gluing machine is working, the induced draft fan 3 is turned on. At this time, the air flow flows from the lower part of the cover body 1 and the middle gap between the two layers of the cover body 1 and is discharged from the air introduction port 2, because the two Layer structure, the negative pressure formed at the edge will be relatively large, and the suction force will be stronger, which overcomes the origina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com