Bags with tear-resistant handles

A technology of handle and connection, applied in bags, sacks, clothing, etc., can solve the problems of overflowing, tearing and wasting of contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

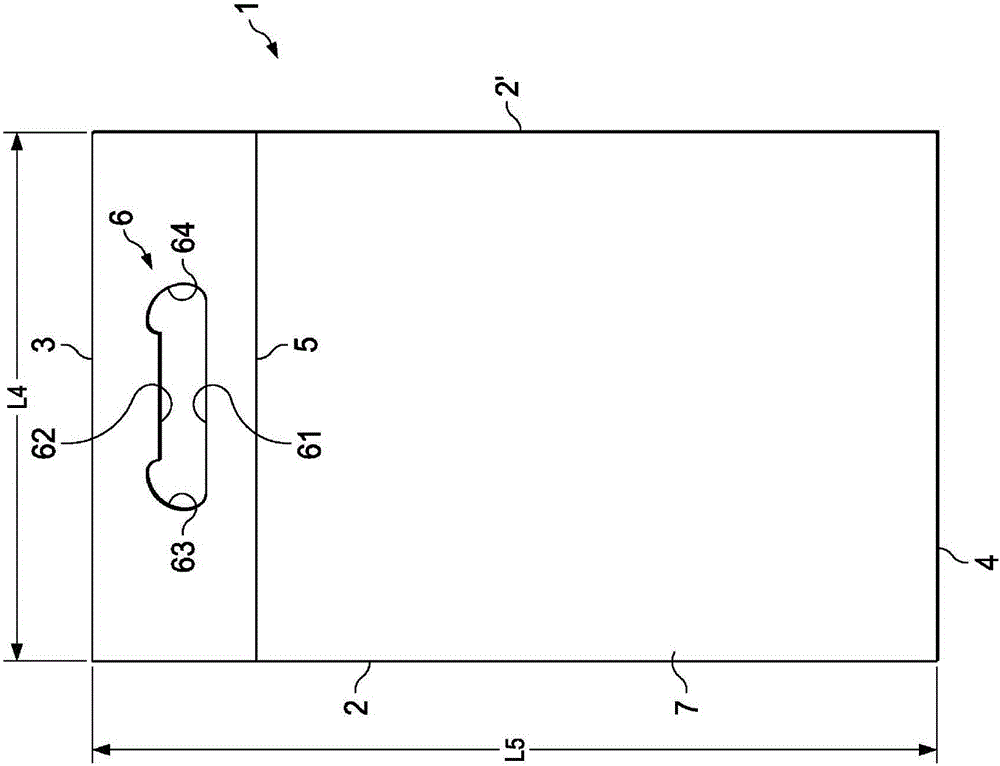

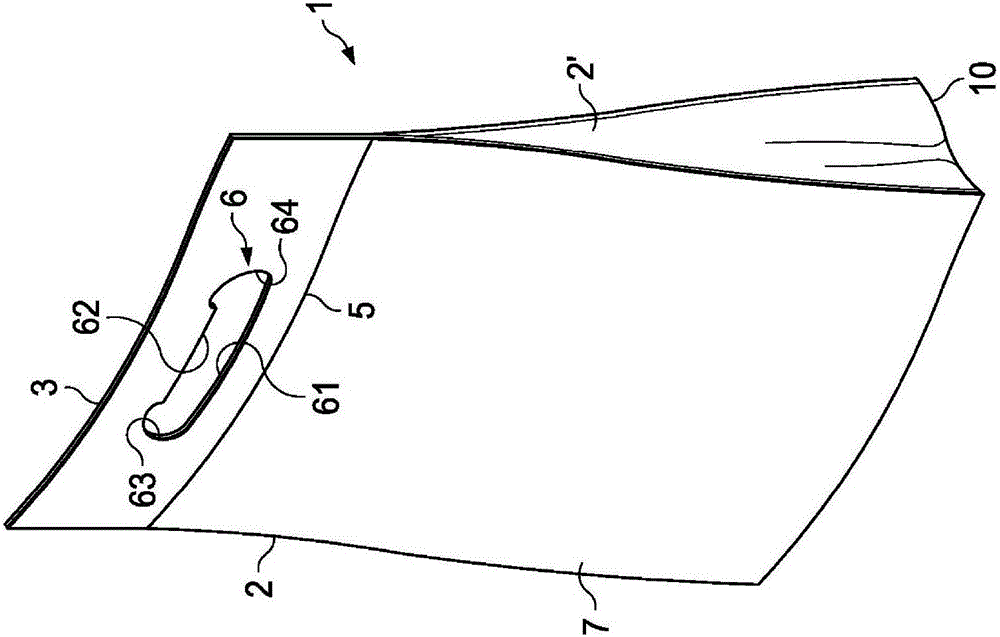

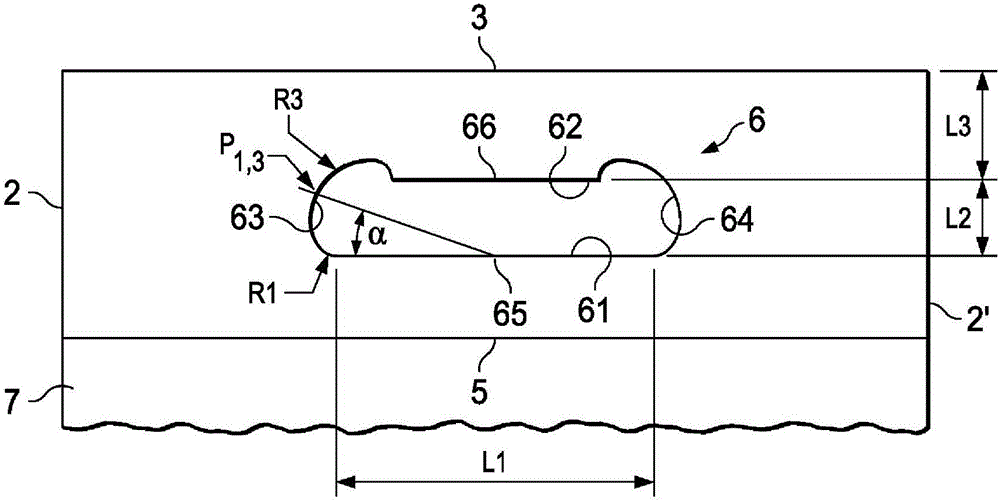

[0029] with two handles (such as Figure 7 As shown, the bags of numbers 6 and 6') were molded with different handle designs listed in Table 1. Comparative Sample 1 was also molded to have the dimensions listed in Table 1. Figure 8 The bag of Comparative Sample 1 is shown. Using the computer simulation software Abaqus / provided by Dassault Systèmes The strength of the bag was tested and the following parameters were used to describe the bag and the test.

[0030] The bag has a rectangular shape with L5 being 395mm and L4 being 275mm. The bag is made of plastic film having a thickness of 92 μm, 0.9539 kg / m 3 Density, 1.568×10 9 Elastic modulus of Pa, and Poisson's ratio of 0.4. The joined front and rear panels in the portion between the tip 3 and the first seal line 5 had a thickness of 165.6 μm. The bottom end of the bag model is fixed in three-dimensional coordinates. The critical point of bag failure was defined as the equivalent plastic strain (PEEQ) at the tip of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com