Battery case and assembly method thereof

A battery box and box body technology, which is applied in the direction of battery pack components, battery isolation from its environment, circuits, etc., can solve the problems that the battery box is easy to enter water, the box body cannot be joined with other components, etc., and achieves convenient loading and unloading work, The effect of avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

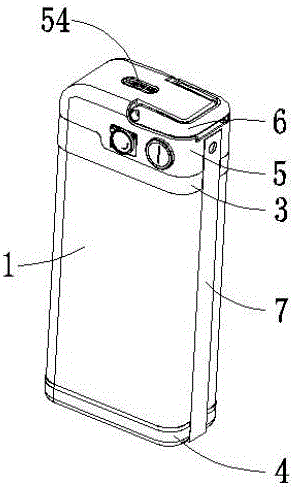

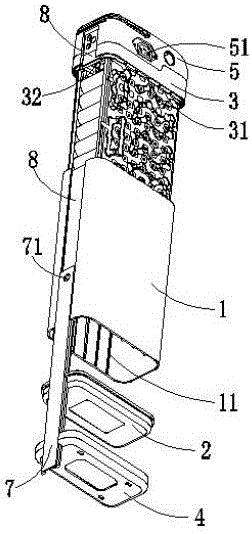

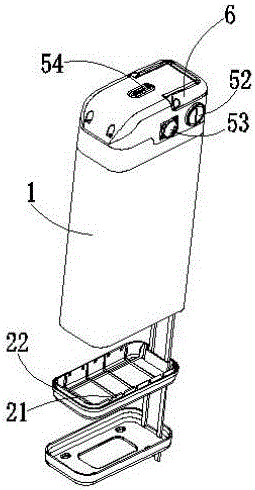

[0039] see Figure 1 to Figure 4 , the invention discloses a battery box, comprising a box body 1, a lower case 2 installed on the bottom of the box body 1, a bottom cover 4 covered on the lower case 2, an upper case 3 installed on the top of the battery case and a cover on the upper case The top cover 5 on the 3 is composed of; the box body 1 is an integrally formed annular cylinder; the upper end surface of the inner wall of the box body 1 extends downward to the lower end surface and is provided with a number of supporting ribs 11, and between the supporting ribs 11 A spacer groove is formed; several projections A21 are extended upwards from the bonding surface of the lower case 2 and the box body 1, and a circle of annular grooves 22 is provided on the outer edge of the projections A21 on the bonding surface. A21 is matched with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com