In-place surface topography detection workbench

A technology for detecting workbench and surface topography, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems that the displacement workbench cannot achieve real-time on-site measurement, the overall volume of the workbench is large, and the detection is troublesome, etc., to achieve The effect of wide application range, shortened height space, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

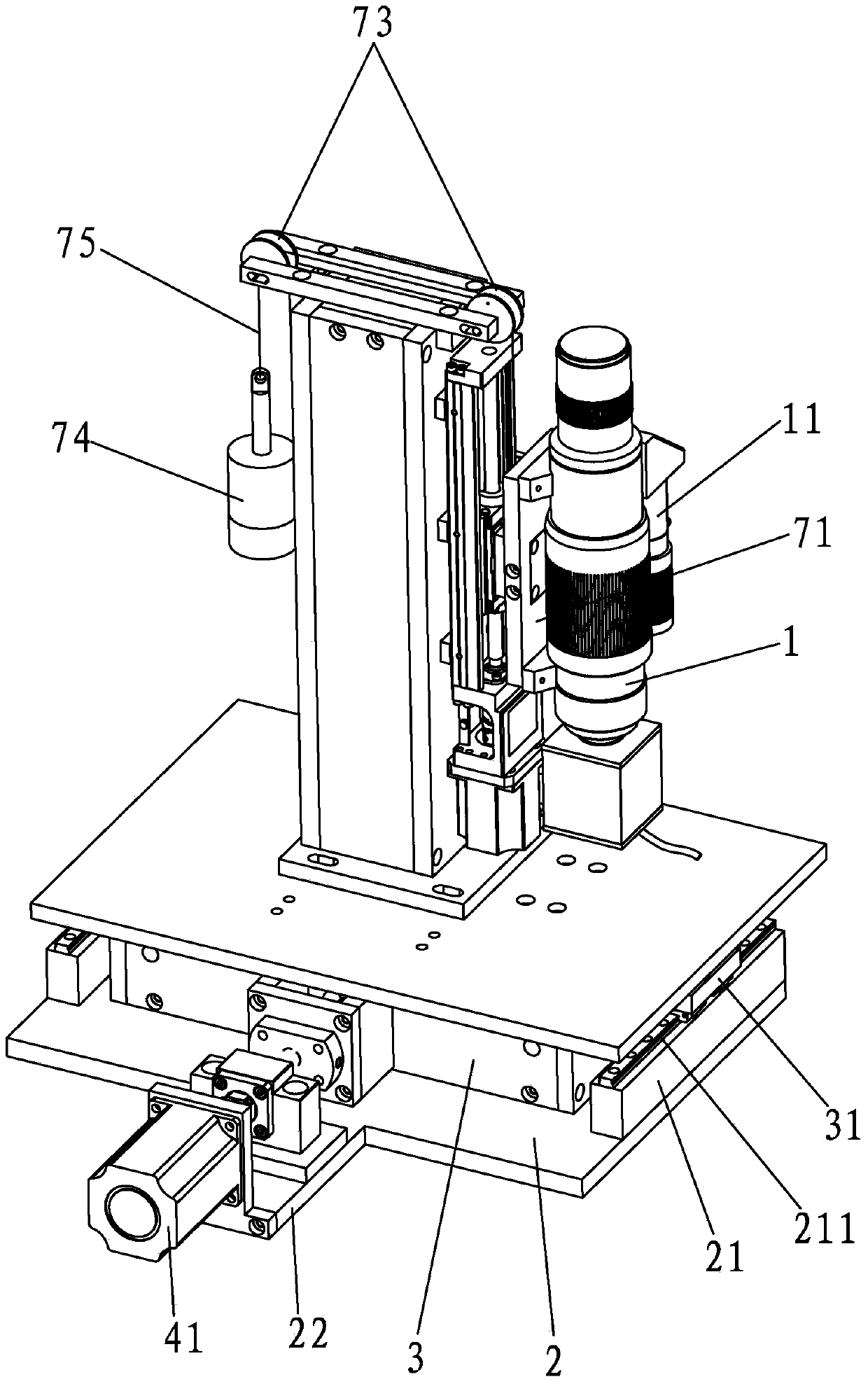

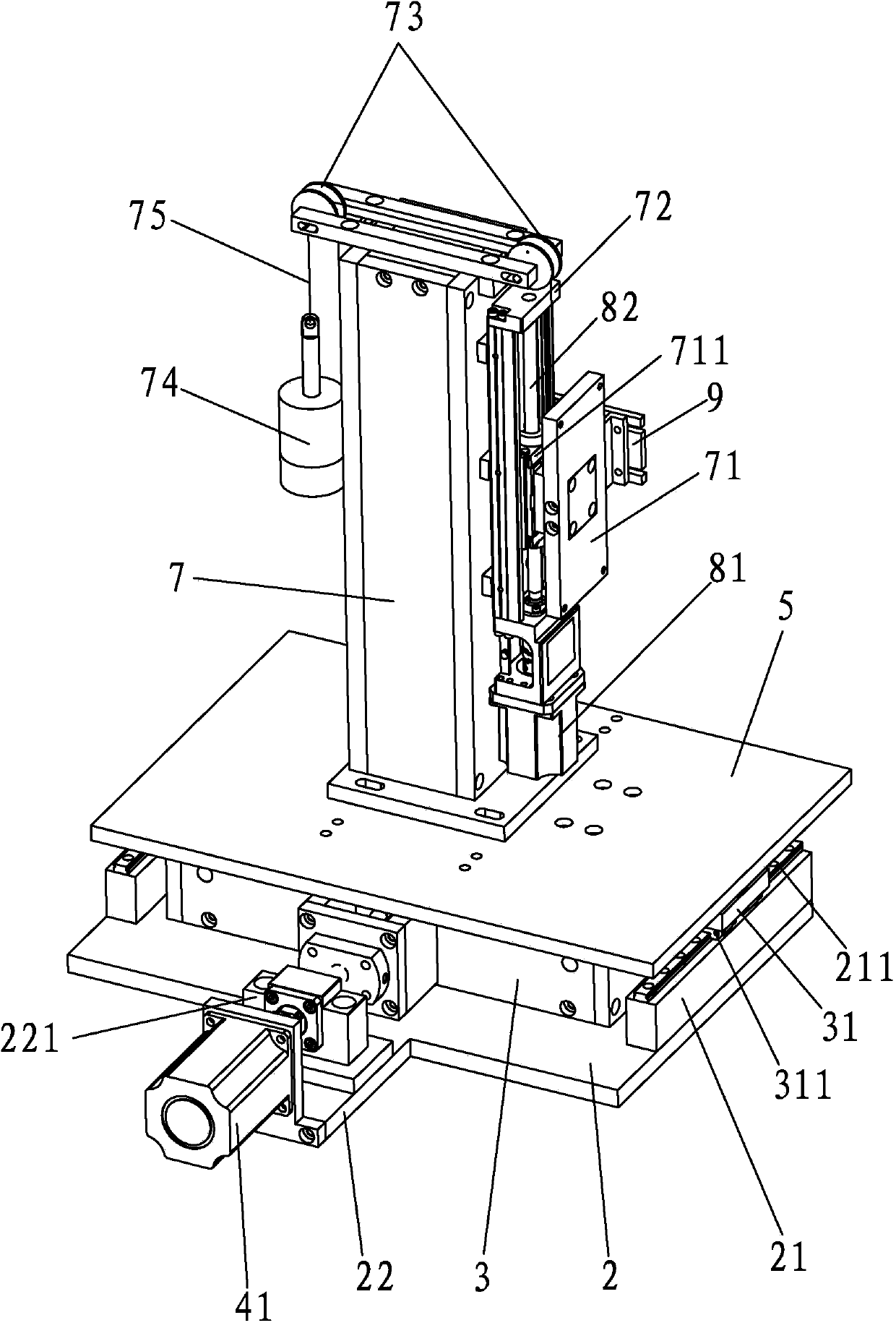

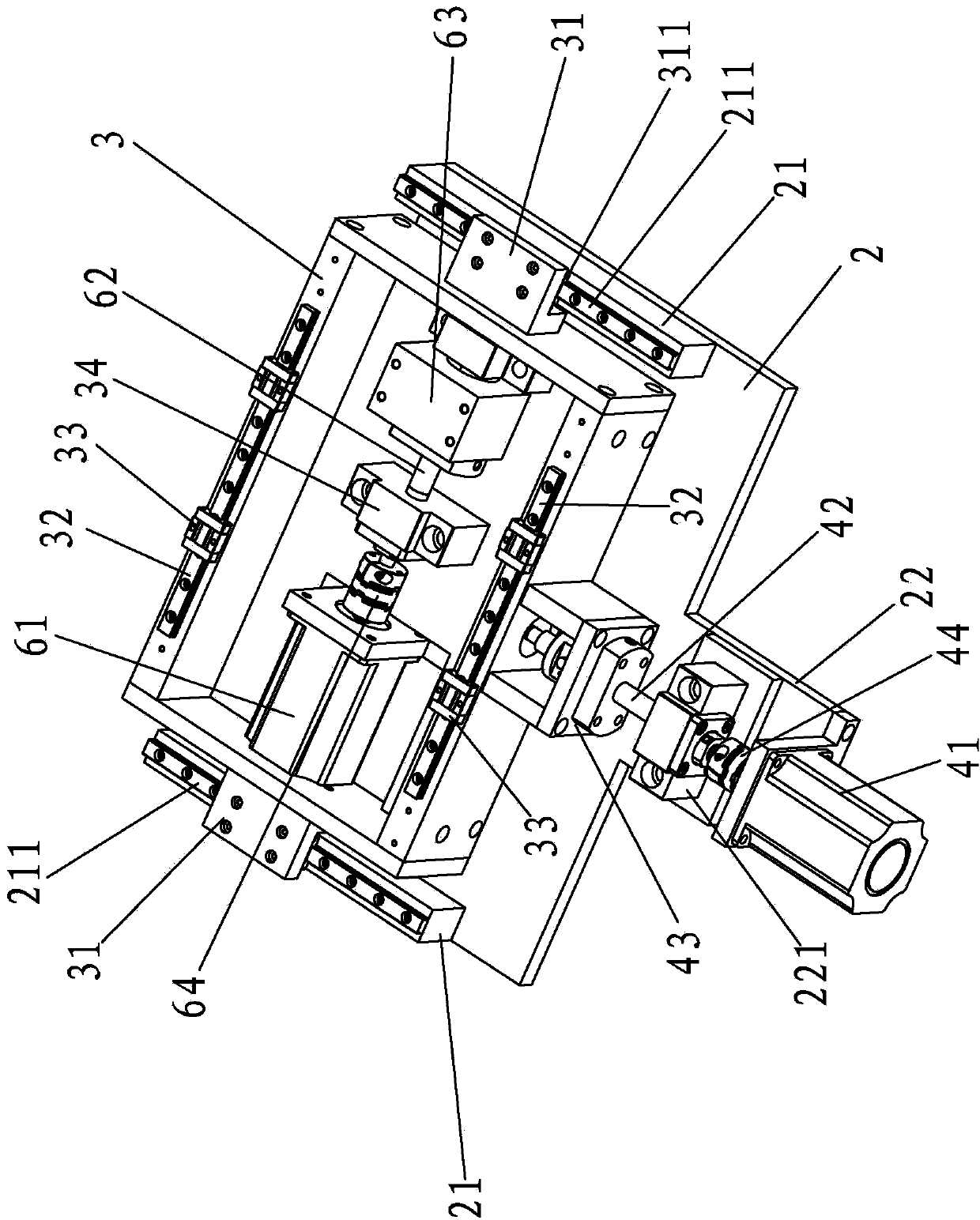

[0036] An in-situ surface topography detection workbench of the present invention, such as Figure 1-3 Shown, comprise support and microscope 1, support comprises lower base plate 2 and upper frame body 3, and this lower base plate 2 is a square plate, and this upper frame body 3 is the hollow square frame body that its upper end is open shape, upper frame body 3. It can be erected above the upper surface of the lower base plate 2 in a manner of translating and sliding along the front-rear direction of the lower base plate 2, that is, the left and right sides of the upper surface of the lower base plate 2 are protrudingly provided with X-axis guide rails 21 extending along the front-rear direction of the lower base plate 2, The upper surface of the X-axis guide rail 21 is protrudingly provided with an X-axis slide rail 211 extending along the length direction of the X-axis guide rail 21, and the left and right outer walls of the upper frame body 3 are provided with one arm fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com