Shock-absorbing method of ring-shaped layered blasting for shallow-buried large-section tunnel passing through existing buildings

A technology with existing buildings and large sections, applied in the line field, can solve problems such as loss, people's lives and property threats, and achieve the effect of reducing vibration speed and avoiding construction disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

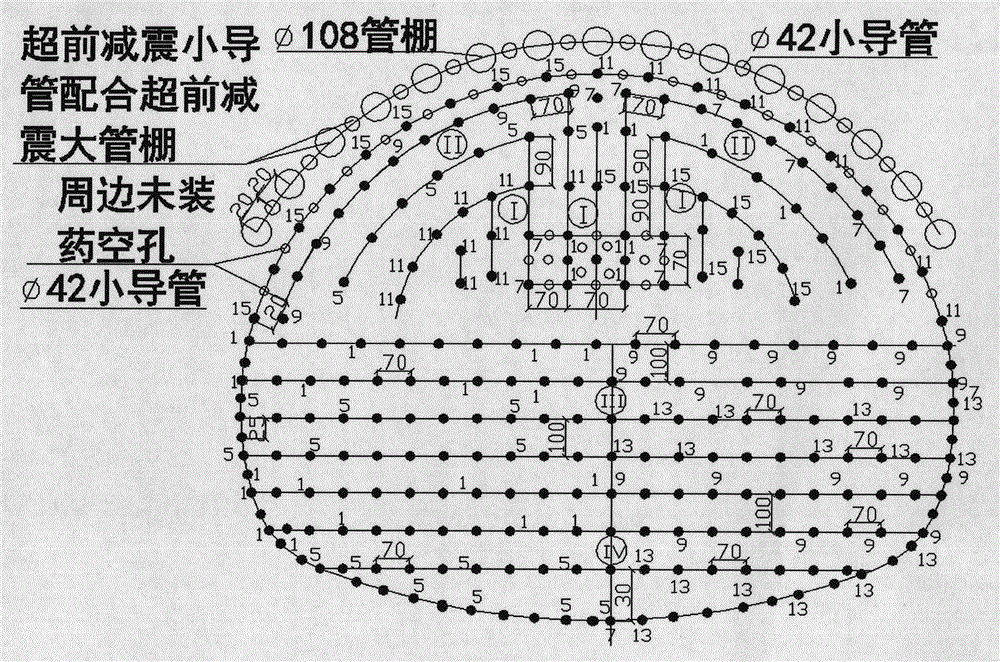

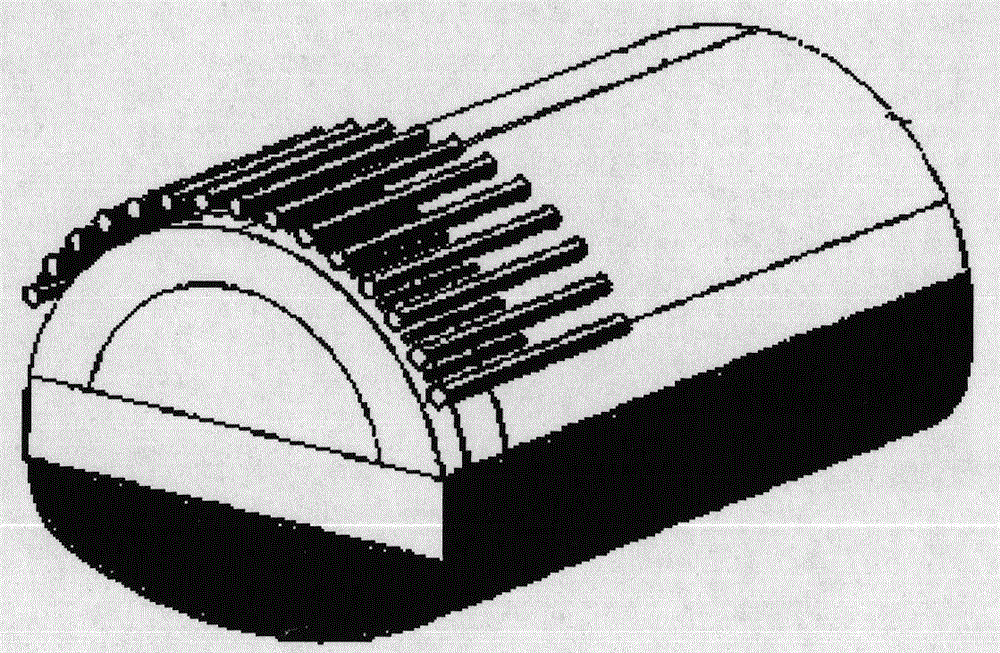

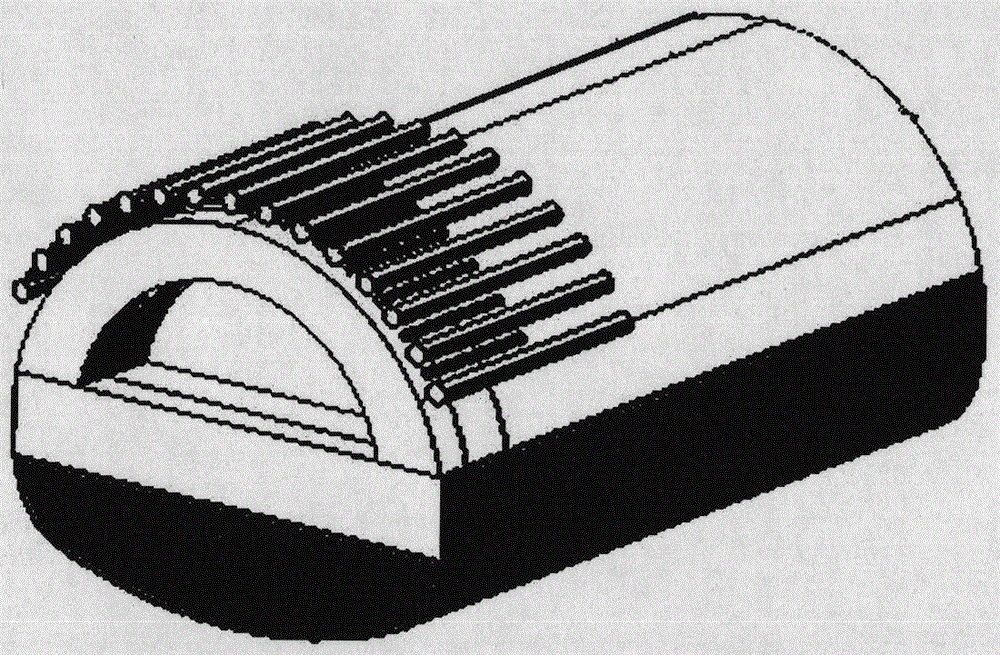

[0018] The technical method of the present invention is made up of three major contents. The first part is the shock-absorbing system—the shock-absorbing large tube shed and the shock-absorbing small conduit; the second part is the controlled blasting excavation system—the empty hole is equipped with wedge-shaped cutting blasting, expanding holes, auxiliary holes and peripheral holes. Layer and segmental blasting excavation; the third part is the layered and segmented blasting system of the middle and lower steps, such as figure 1 shown.

[0019] A shock-absorbing method for ring-shaped layered blasting in which a shallow-buried large-section tunnel passes under an existing building, comprising the following steps:

[0020] 1) Firstly, steel pipes with a spacing of 40cm and a diameter of 108mm are drilled within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com