Sludge Dewatering System

A sludge dehydration and sludge technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of deep buried pipeline, large amount of foundation engineering, inconvenient removal, scattered installation and combination, etc., and achieves easy installation and maintenance, Eliminate cumbersome installation and avoid the effect of odor leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

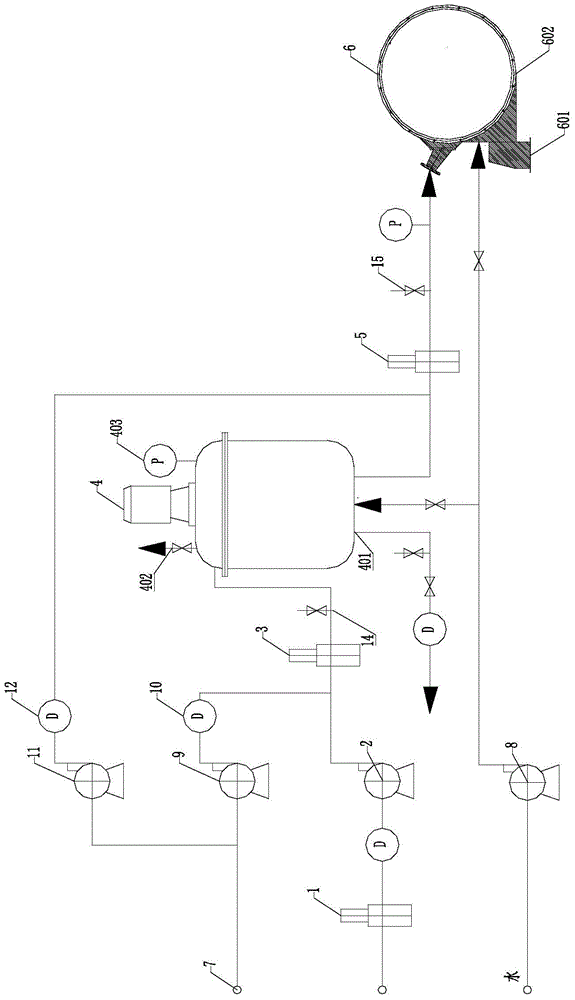

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] Please refer to figure 1 , and the figure is a working principle diagram of the sludge dewatering system of the present invention.

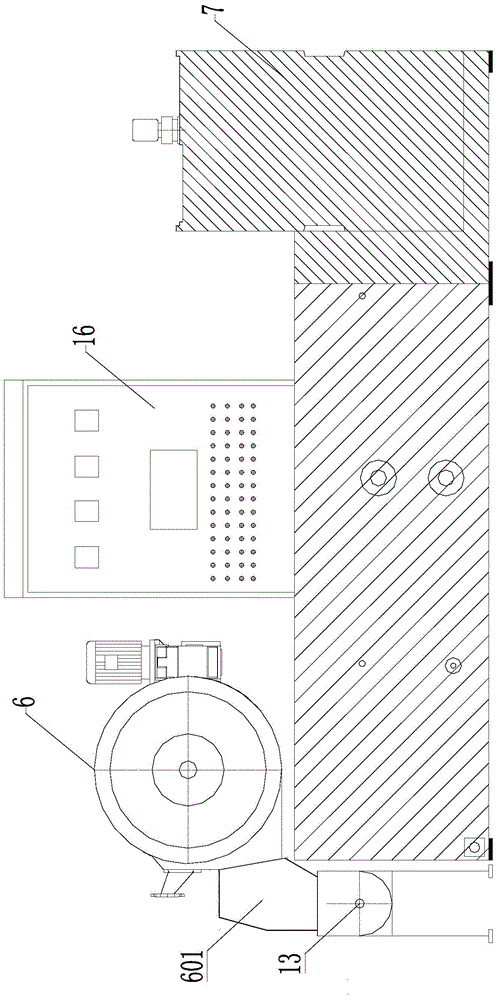

[0017] A sludge dewatering system, including a sludge cutter 1, a sludge pump 2, a first stirring body 3, a stirring thickening tank 4, a second stirring body 5 and a rotary extrusion filter 6 connected in sequence, in the Between the sludge pump 2 and the first stirring body, there is a drug-filling chamber 7 filled with a flocculant. The pipeline between the stirring and concentrating tank 4 and the second stirring body 5 is connected to the The brewing chamber 7 is connected, and the rotary squeeze filter 6 is provided with a filter cake outlet 601 and a filtrate outlet 602 . The sludge water in the sludge tank enters the first stirring body 3, the thickening stirring body 4 and the second stirring body 5 sequentially through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com