Fully-automatic bagged cement loader

A car loading machine, fully automatic technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve problems such as difficult to tilt the conveying device 5 to a stable state, poor working environment for workers, unfavorable health of workers, etc., to achieve simple structure, Low cost, good health effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

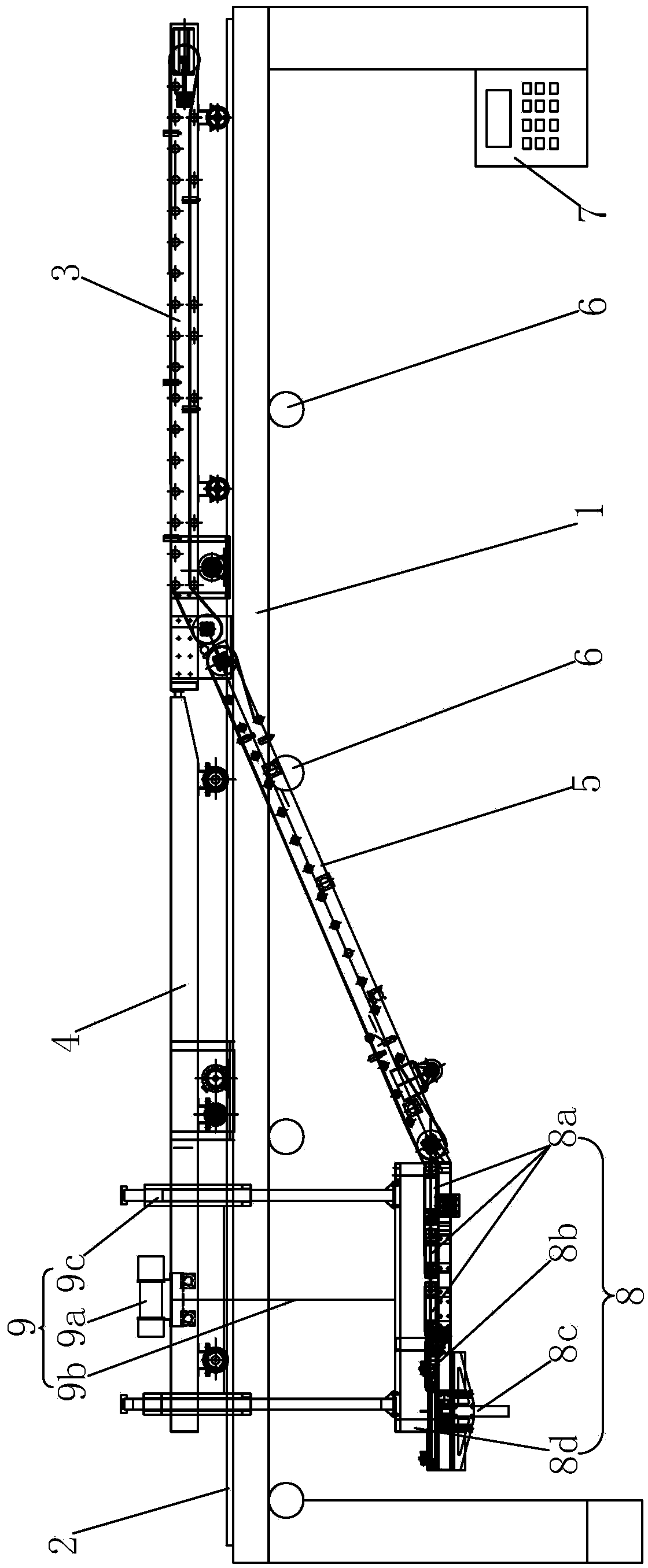

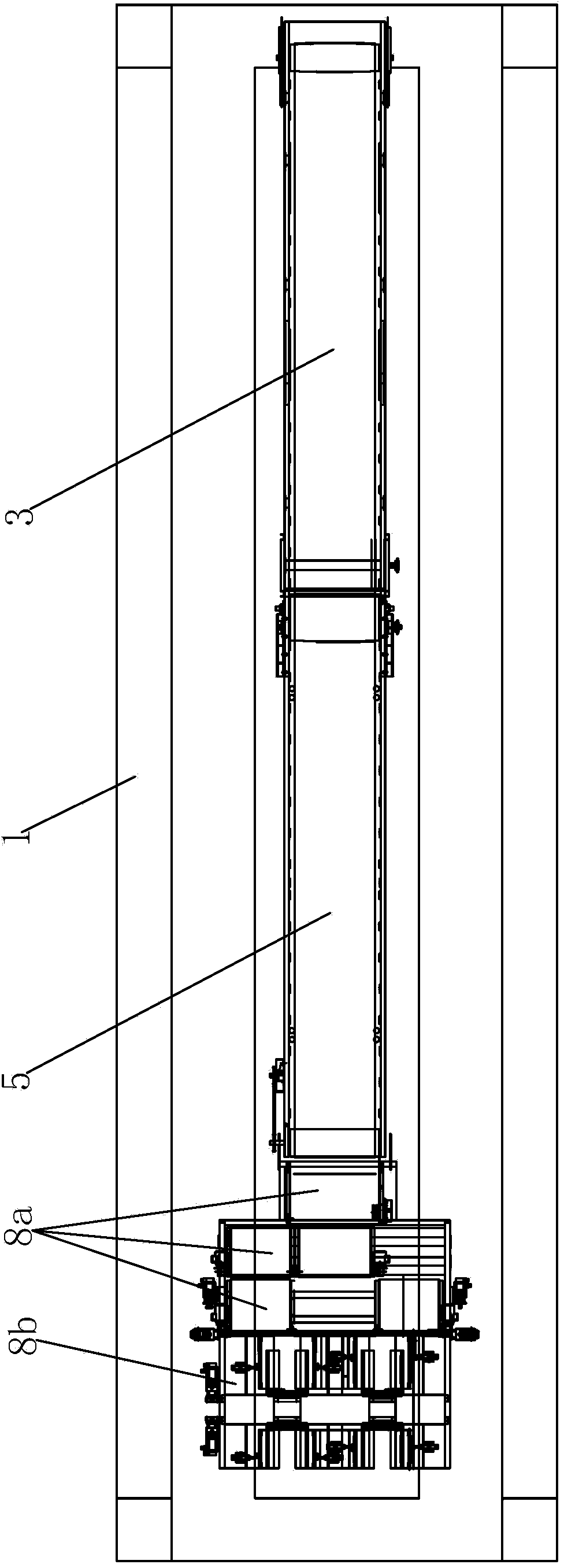

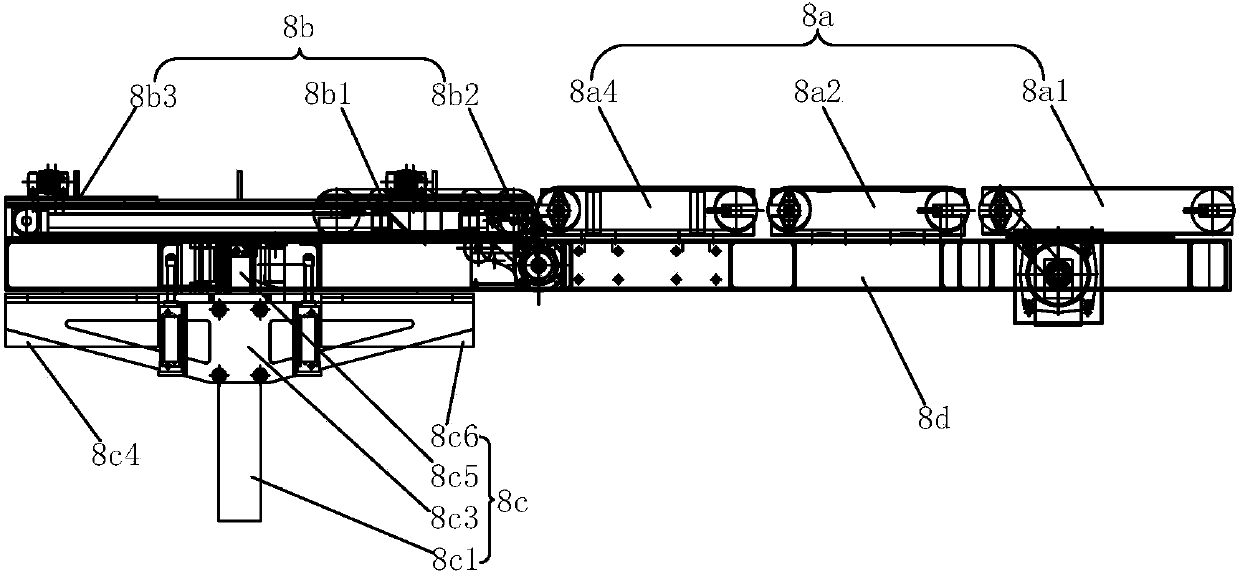

[0049] This embodiment provides a fully automatic bagged cement loading machine, which includes a guide rail 2 fixed on the factory building 1, a horizontal conveying device 3 rolling on the guide rail 2, and a rolling installation on the guide rail 2. The walking device 4 connected to the output end of the horizontal conveying device 3, the inclined conveying device 5, the positioning system 6 and the controller 7, the input end of the inclined conveying device 5 is docked with the output end of the horizontal conveying device 3, and the The output end of the inclined conveying device 5 is docked with a loading and palletizing main machine 8, and the loading and palletizing main machine 8 is hoisted on the walking device 4 by a lifting device 9; the loading and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com