Scraping device for centrifuge

A centrifuge and scraping technology, which is applied in the direction of centrifuges, etc., can solve problems such as high labor intensity, deformation of the casing, and filter cake falling off, and achieve the effect of reducing costs, saving manpower, and scraping materials thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

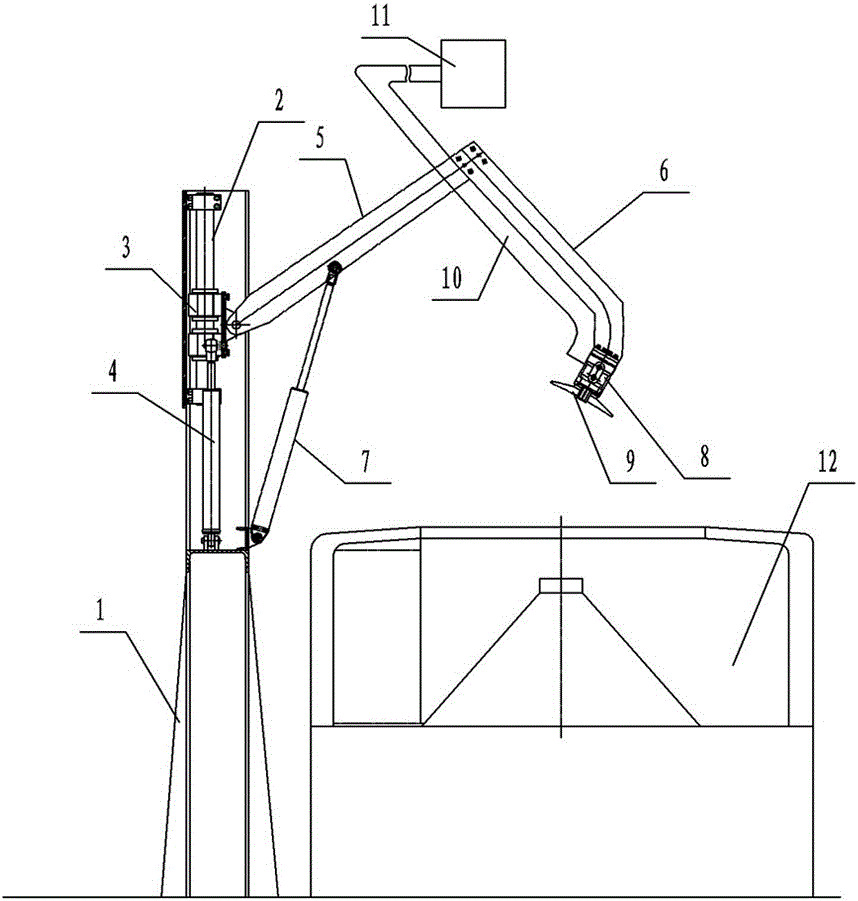

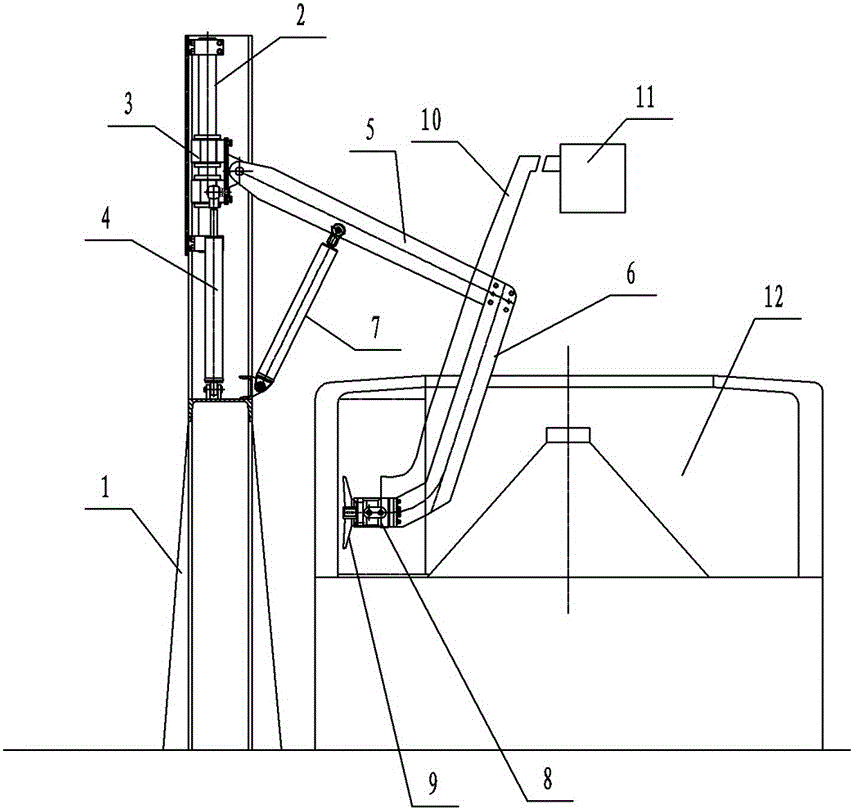

[0010] The scraping device for the centrifuge includes a base 1, the base 1 is installed near the centrifuge 12, a vertical slide rail 2 is set on the upper part of the base 1, a trolley 3 is set on the slide rail, the upper and lower hydraulic devices 4 are connected to the lower part of the trolley 3, and the upper and lower hydraulic devices 4 Control the up and down movement of the trolley 3, the trolley 3 is hinged with the mechanical arm, and the mechanical arm is divided into two parts, the upper section and the lower section. The angle between the upper section 5 of the mechanical arm and the lower section 6 of the mechanical arm is 90-110 degrees. The hydraulic device 7 is connected, and the flipping hydraulic device 7 drives the mechanical arm to rotate along the end of the upper section 5 of the mechanical arm. The end of the lower section 6 of the mechanical arm is connected to the hydraulic motor 8, and the hydraulic motor 8 is connected to the scraper 9. When worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com