Recipe and production process of shark fin golden cake

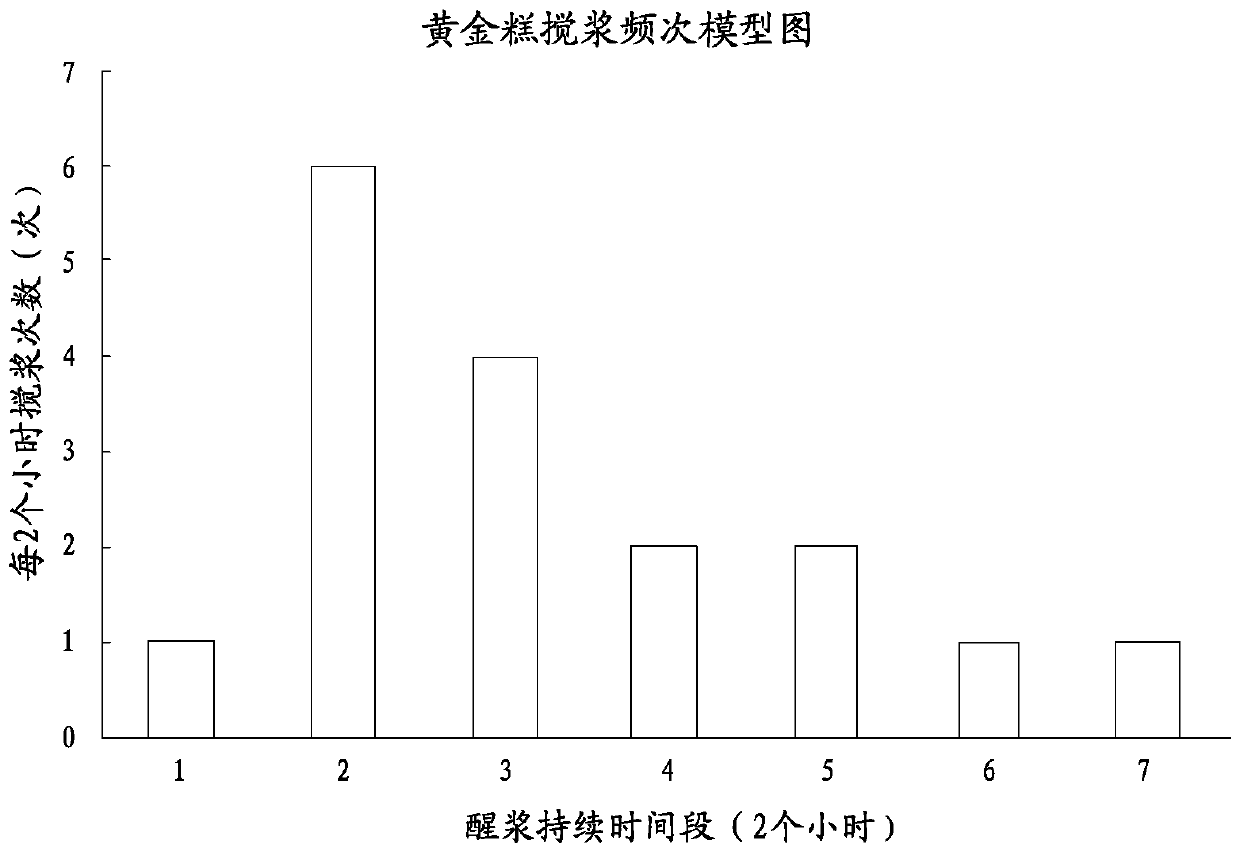

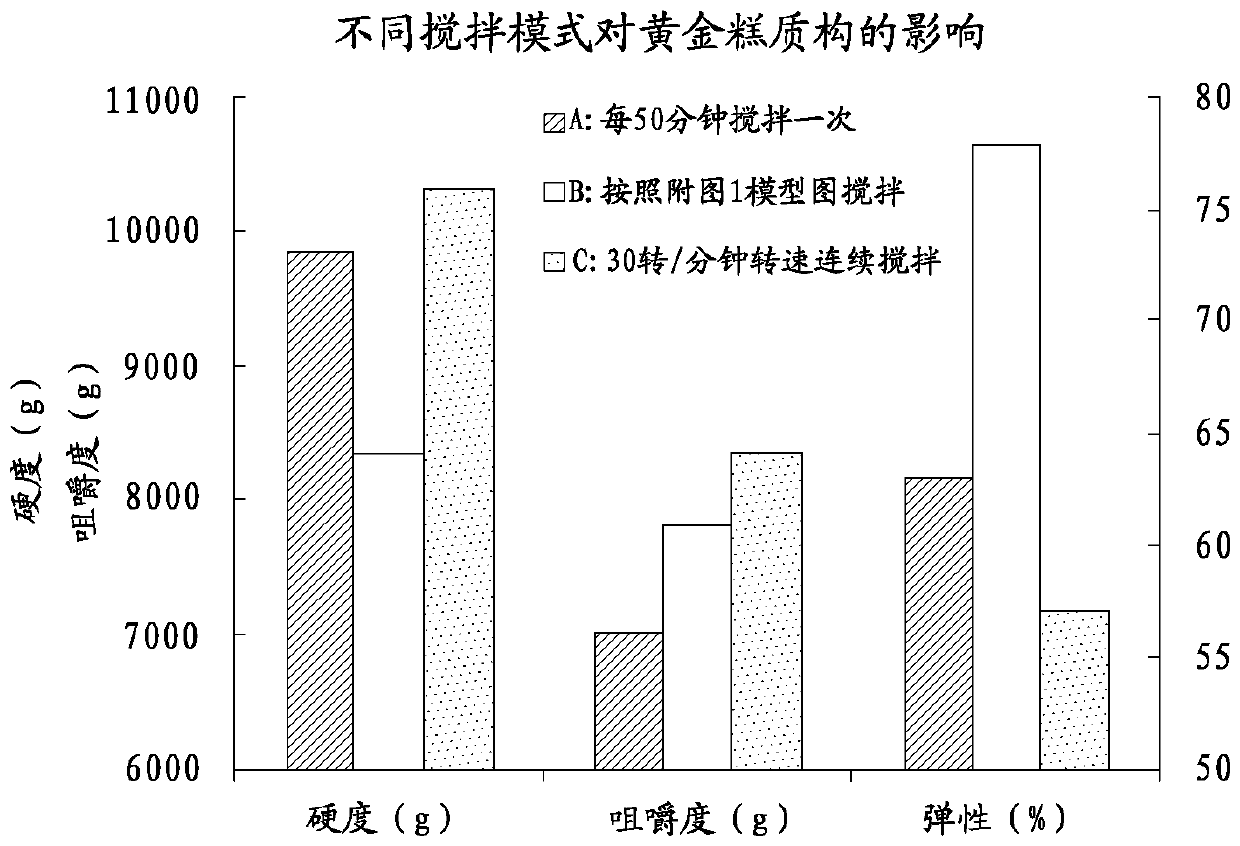

A production process and gold technology, which is applied in the processing of dough, baking, baked goods, etc., and can solve the problems of short wake-up time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

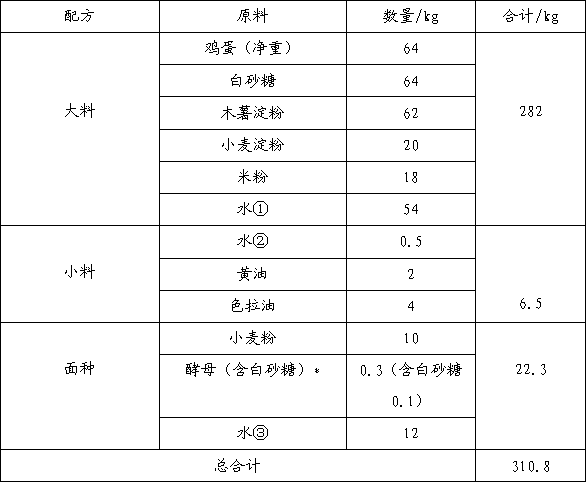

[0026] The invention discloses a formula of shark fin golden cake, the content of each component in weight percentage is: egg liquid: 18-25%; white granulated sugar: 17-23%; tapioca starch: 17-21%; wheat starch: 5-8%; rice flour: 4-7%; water: 20-25%; butter: 0.5-0.8%; salad oil: 1.1-1.5%; flour: 3.0-3.5%; yeast: 0.06-0.07%.

[0027] The specific production process is as follows:

[0028] 1. Slurry production:

[0029] First, pour white granulated sugar, tapioca starch, rice flour, wheat starch, and 94% water into the jacketed pot quantitatively and stir to make them even, about 3 minutes;

[0030] Next, add the filtered egg liquid into the sandwich pot, stir to make it even, about 5 minutes;

[0031] Furthermore, turn on the steam (0.2MPa) to heat up the slurry, and measure the temperature. When the temperature of the slurry rises to 37±1°C, stop the steam; at this time, the slurry is uniform, and there is no visible egg liquid, white sugar particles, Starch granules, etc.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com