Papermaking device, small paper machine and papermaking method

A paper-making device and technology for paper-making machines, applied in paper-making, paper-making, textiles and paper-making, etc., can solve the problems of slow paper-making speed, poor suction efficiency, excess suction capacity of vacuum pump, etc., and achieve the effect of restraining power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

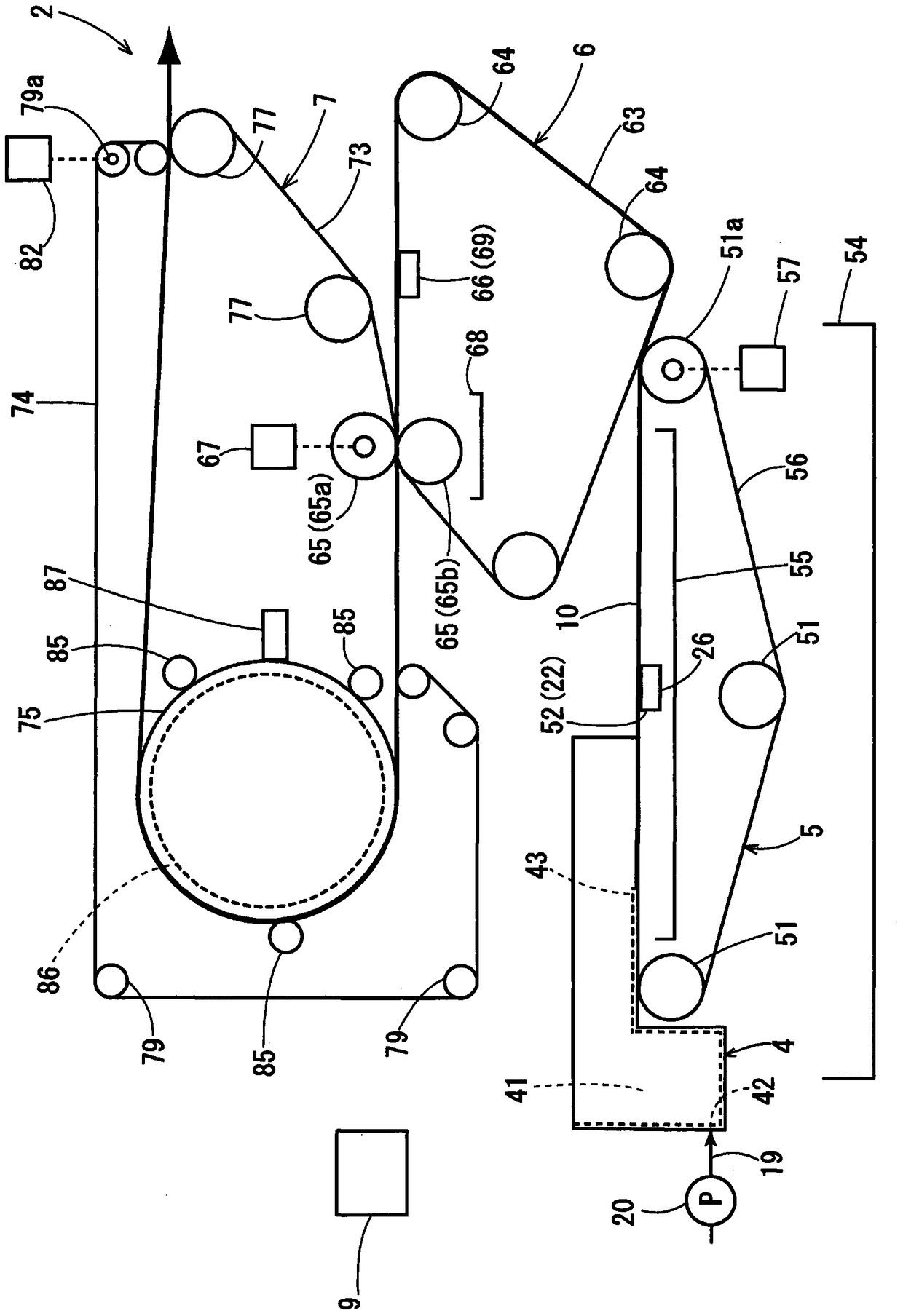

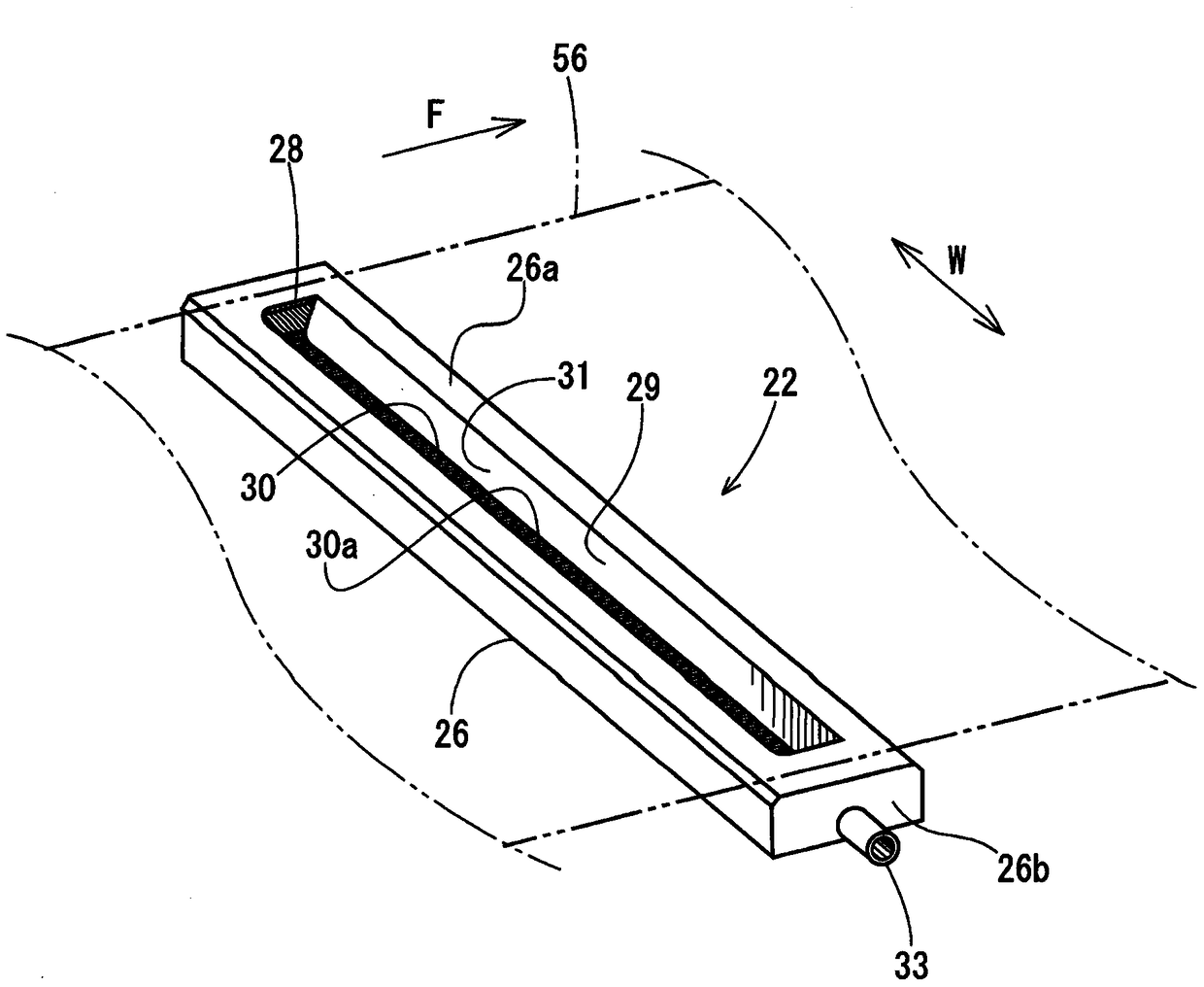

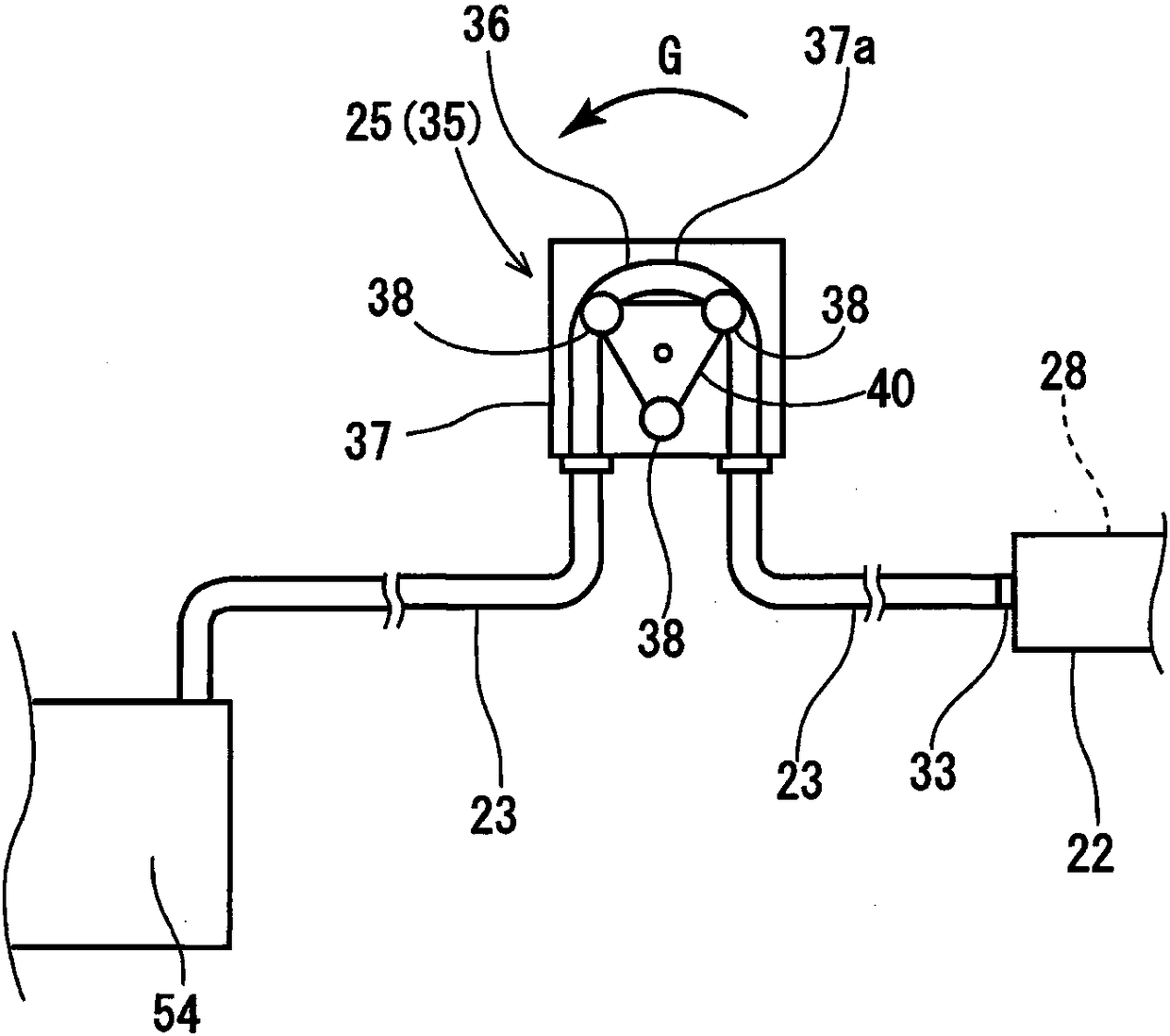

[0040] Embodiments of the present invention will be described below based on the drawings. The papermaking apparatus of the present invention constitutes a part of a small paper machine that can be installed in an office. In addition, the above-mentioned paper machine is a waste paper regeneration processing device, which can use waste paper generated in offices as a papermaking raw material, and regenerate waste paper to produce recycled paper.

[0041] Although not shown in the figure, a paper machine as a waste paper recycling apparatus includes a pulp manufacturing apparatus, a deinking apparatus, and a cutting apparatus in addition to a papermaking apparatus. Pulp manufacturing equipment and deinking equipment are installed in the front section of the papermaking equipment. The pulp manufacturing device produces pulp-containing liquid by adding water to waste paper and stirring it, and decomposing the waste paper. The deinking device performs deinking treatment to separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com