Full-automatic oil seal trimming device

A fully automatic, oil-sealed technology, applied in metal processing, etc., can solve the problems of unguaranteed quality, low degree of automation, high labor intensity, etc., and achieve the effect of convenient pruning operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

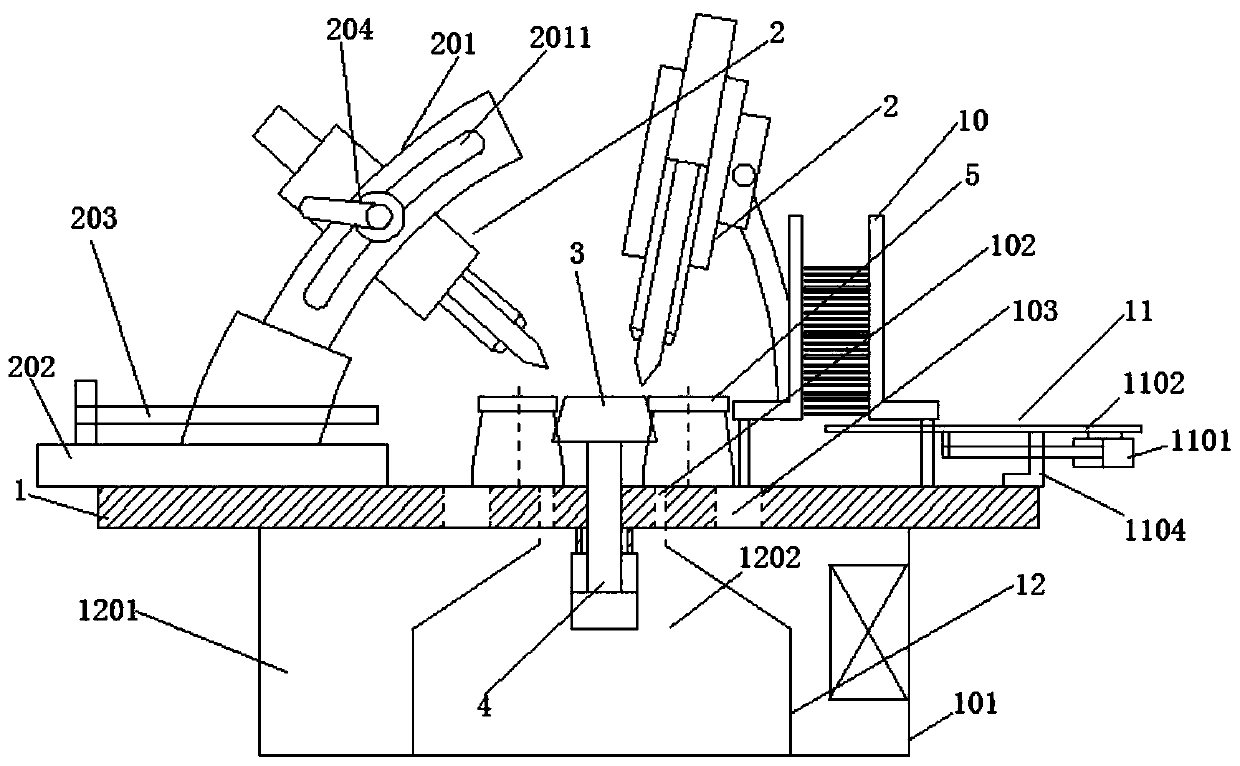

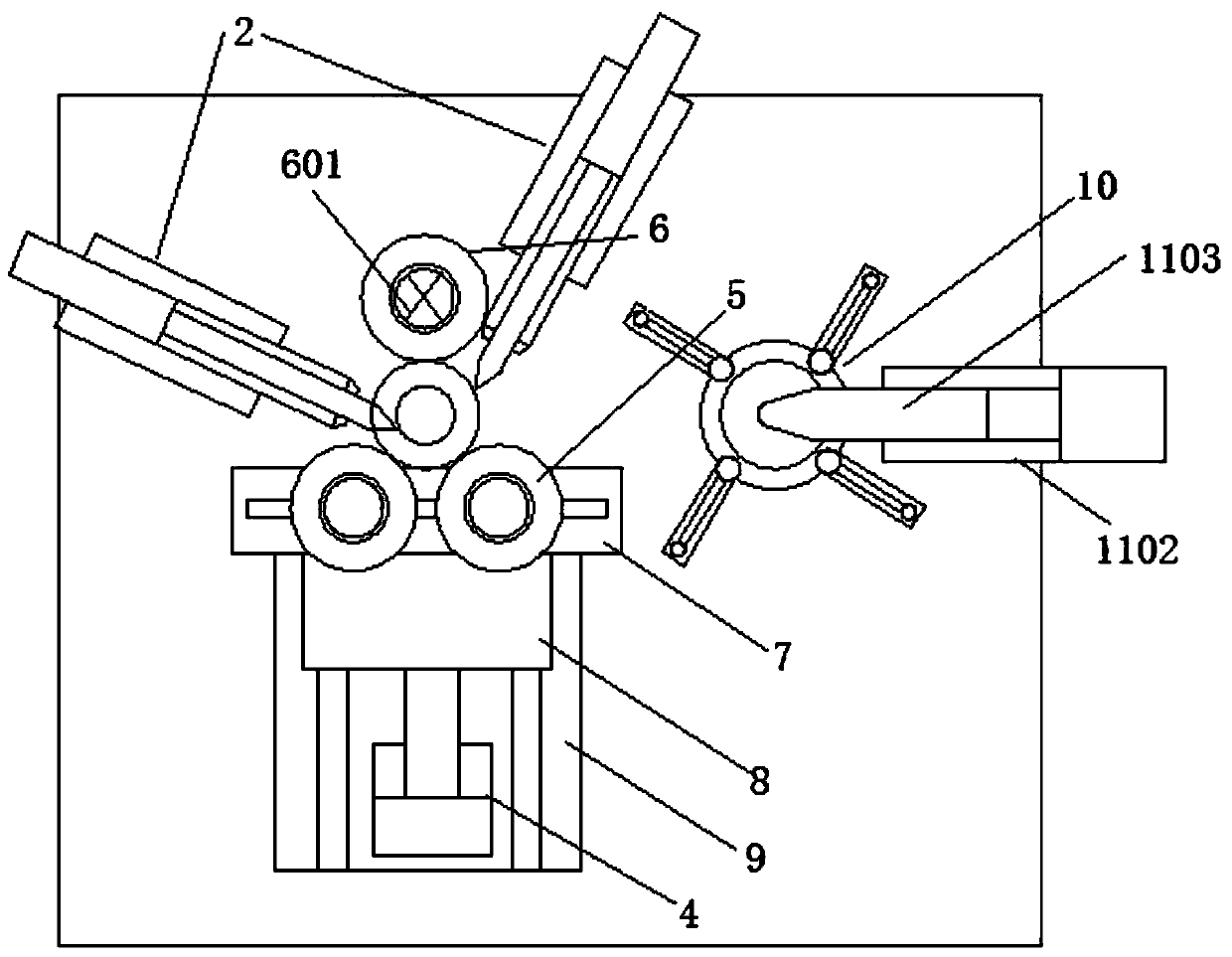

[0017] See attached picture,

[0018] A full-automatic oil seal trimming device, including a workbench 1, a combined telescopic knife 2, and a box body 101 supporting the workbench 1 on the ground, and a telescopic material receiving tray 3 for receiving and rotating materials is provided at the center of the workbench 1, A telescopic cylinder 4 is provided at the lower end of the telescopic material receiving tray 3, and a pair of movable runners 5 and a driving runner 6 for material positioning and rotation are arranged on the outer side of the telescopic feeding tray 3. The three runners are arranged in a triangle, and the driving runners 6. The lower end is connected to the drive motor 601. A pair of movable runners 5 are fixed on the fixed plate 7. The rear end of the fixed plate 7 is connected to the sliding block 8, and the rear end of the sliding block 8 is connected to the telescopic cylinder. 4. The sliding block 8 is slidably installed on the runner fixing seat 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com