Boiler comprising a sealed housing

A technology for kettles and casings, which is applied to water boiling utensils, cooking utensils, household appliances, etc., and can solve problems such as damage control devices, damage control devices, water infiltration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

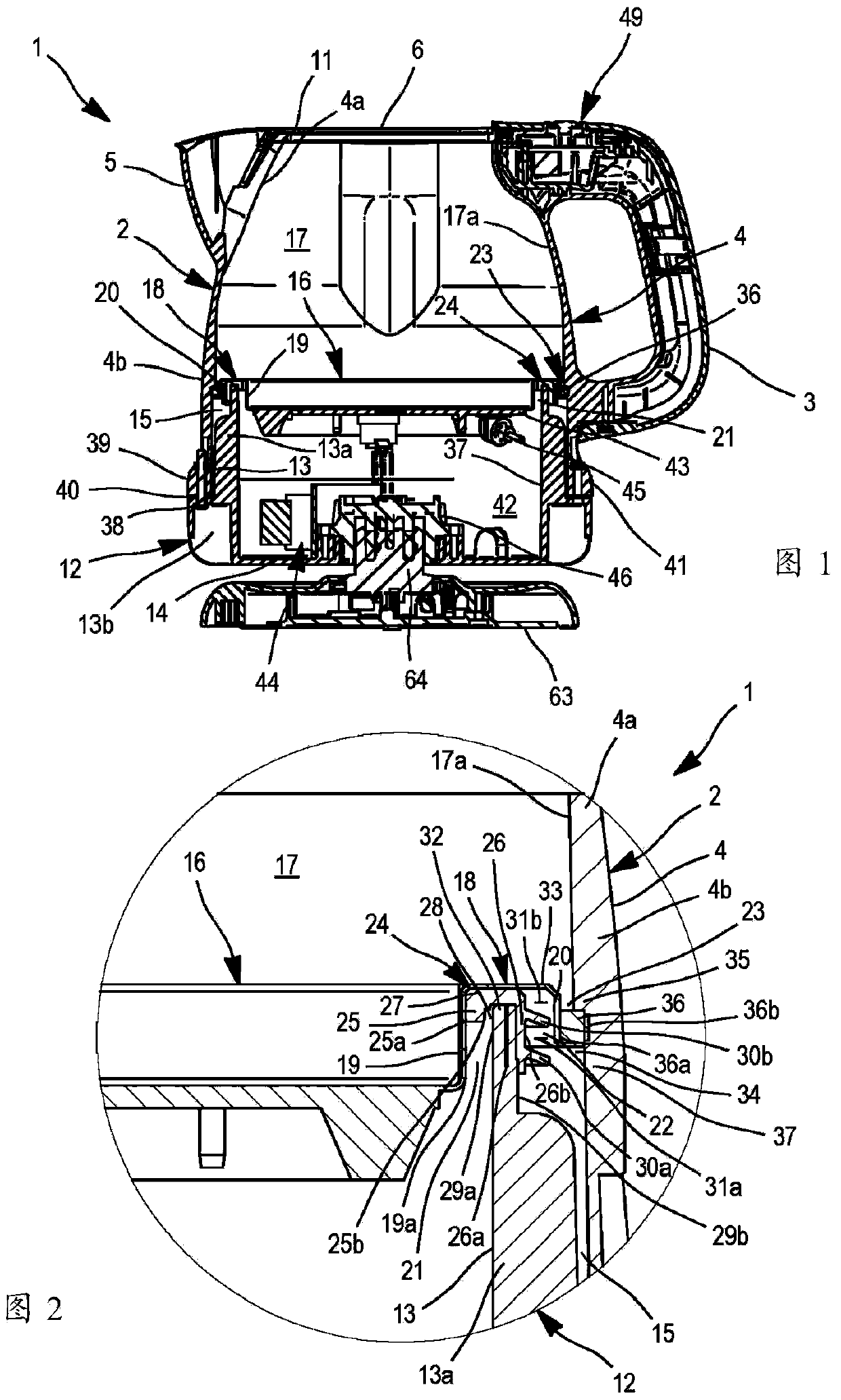

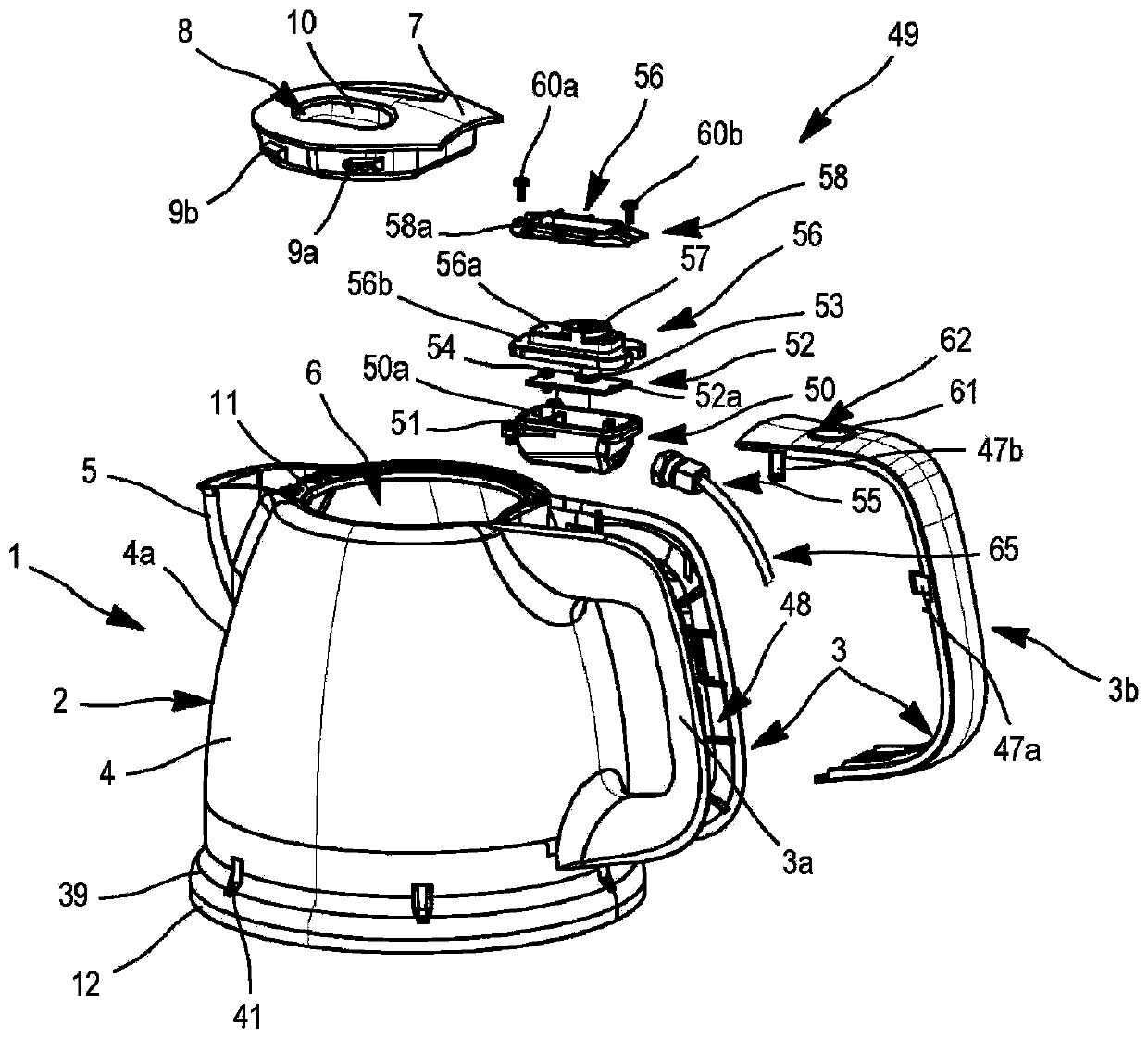

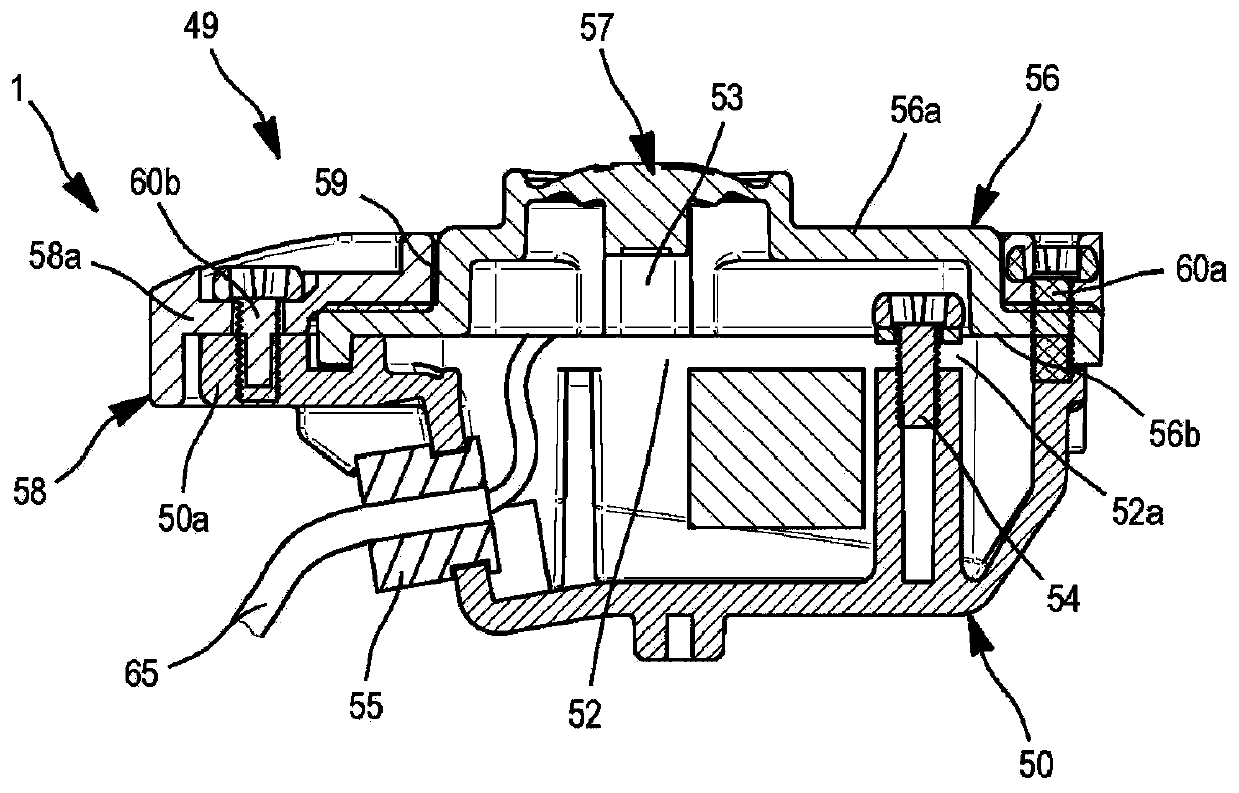

[0035] Such as Figures 1 to 3 As shown, the kettle 1 comprises a body 2 made of plastic material ensuring very low thermal conductivity in order to avoid scalding the user when operating the kettle with boiling water. In order to allow the operation of the kettle 1 , the kettle comprises a handle 3 fixed to the body 2 . Preferably, the body 2 and the handle 3 are made in a single piece by moulding. The body 2 comprises a peripheral outer wall 4 of preferably circular shape, which extends downwards. The upper part 4a of the outer wall 4 comprises a pouring spout 5 which allows boiling water to be poured out when the main body 2 is tilted. This upper part 4 a comprises an opening 6 for receiving a closing cover 7 . This cover 7 comprises an opening / closing system 8 which allows the cover to be snapped onto the upper part 4 a of the body when it is placed at the opening 6 . The opening / closing system 8 comprises pins 9 a , 9 b retractable when the activation button 10 is act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com