Micro-aeration nitrification combined with sludge fermentation coupled with denitrification method to treat domestic sewage with low carbon-nitrogen ratio

A low-carbon-to-nitrogen ratio, domestic sewage technology, applied in biological sludge treatment, aerobic and anaerobic process treatment, etc. problems, to achieve the effect of promoting digestion efficiency and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

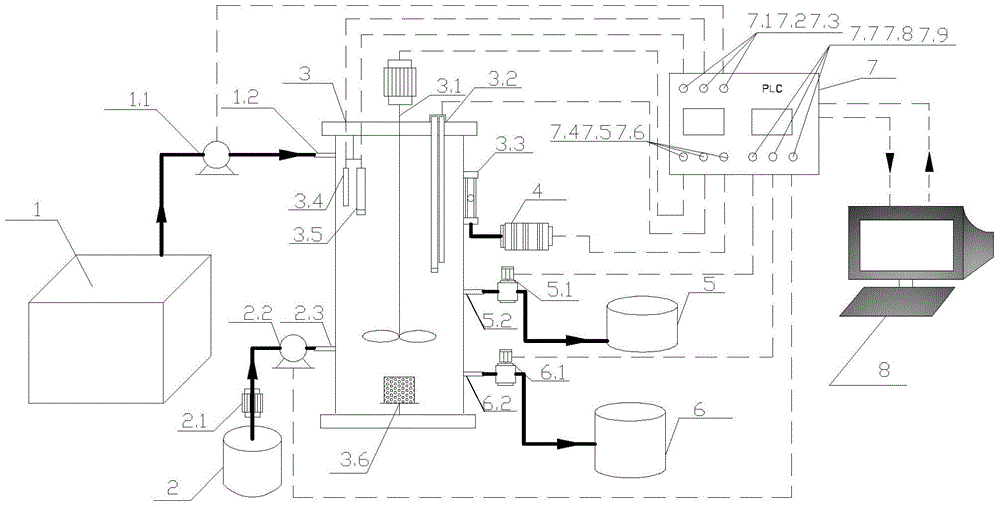

[0040] combined with figure 1 The present invention will be further described with implementation examples.

[0041]A method for micro-aeration nitrification combined with sludge fermentation coupled with denitrification to treat domestic sewage with a low carbon-to-nitrogen ratio. The device includes: a raw water tank 1, a mud storage tank 2, a main reactor 3, an air compressor 4, a drainage tank 5, Sludge discharge tank 6, programmable process controller 7 and computer 8. Micro-aeration combined with sludge fermentation coupled denitrification main reactor 3 adopts a cylindrical structure, with No. 1 agitator 3.1, temperature sensor 3.2, pH sensor 3.4, DO sensor 3.5 on the top, and gas flow meter 3.3 on the side. A water inlet pipe 1.2, a mud inlet pipe 2.3, a water outlet pipe 5.2, and a mud discharge pipe 6.2 are arranged on the sides, and an aeration device 3.6 is arranged at the bottom.

[0042] The raw water tank 1 is connected to the main reactor 3 through the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com