Repeatedly opened and closed anti-leakage valve with cylindrical panel valve sealing structure

A valve sealing and panel technology, which is applied in the field of safety isolation devices, can solve problems affecting the opening of plate valves, and achieve long-term safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical means and functions adopted by the present invention to achieve the predetermined technical purpose, the structure and working process of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0045] The anti-leakage valve described in the present invention needs to be opened with a special switch tool. The switch tool can be a switch tool in the prior art, such as the switch tool described in the Chinese utility model patent (CN201507274U). The invention also provides a A switch tool with more reliable performance, the detailed structure is described in the second part below.

[0046] 1. Anti-leakage valve

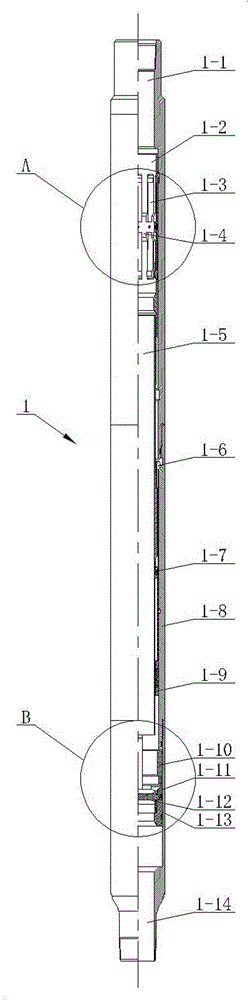

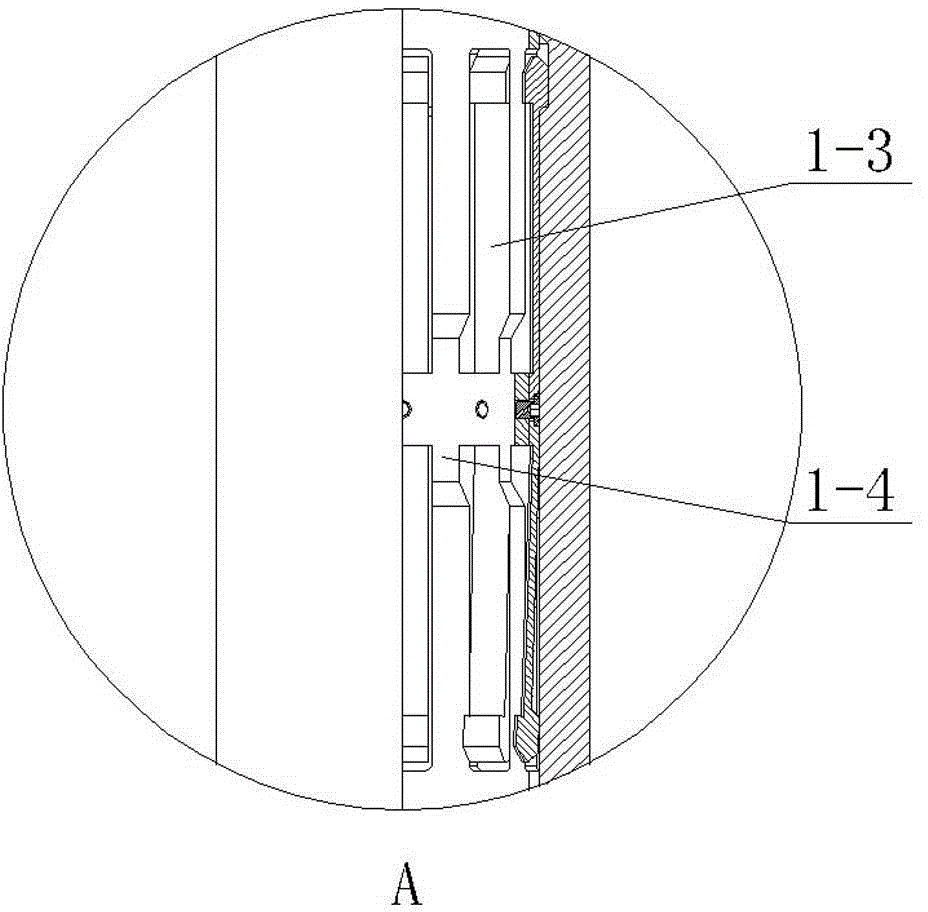

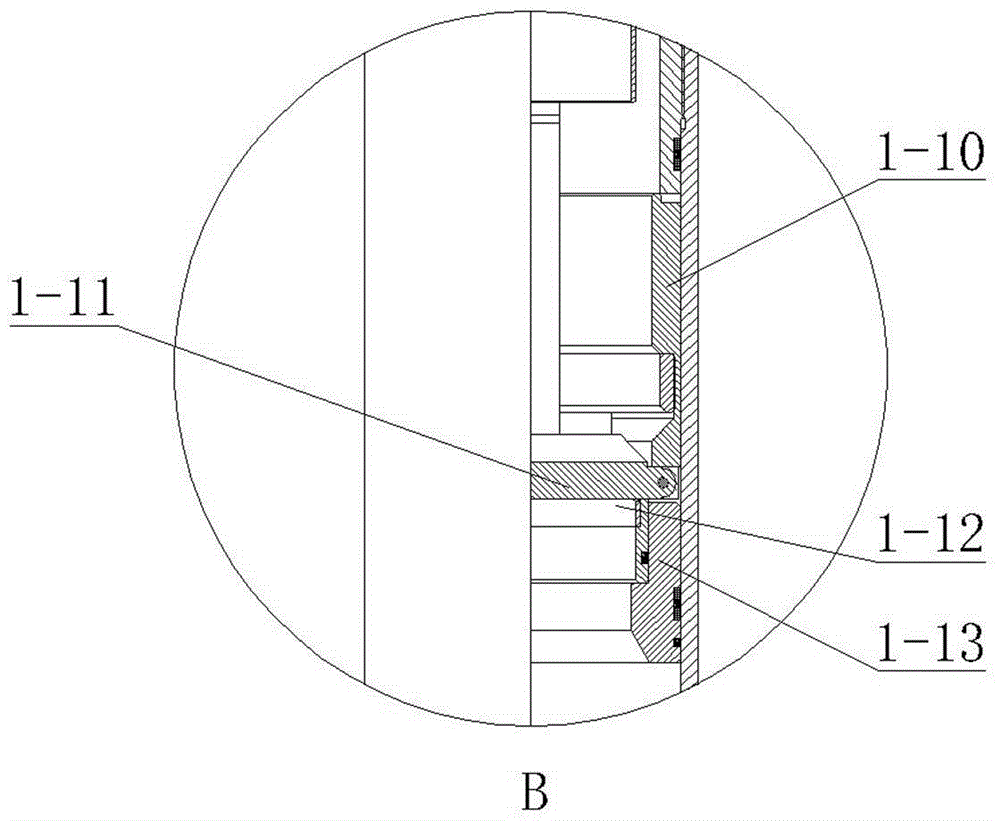

[0047] Such as figure 1 , Figure 4 , Figure 9 Shown is a schematic diagram of the anti-leakage valve 1 used in the present invention. The anti-leakage valve 1 includes a valve body, and the valve body is composed of a positioning joint 1-1, a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com