A built-in tire burst emergency device with multiple oil cylinders

An emergency device and oil cylinder technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as power supply for difficult vehicles, and achieve the effect of smooth and comfortable driving of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

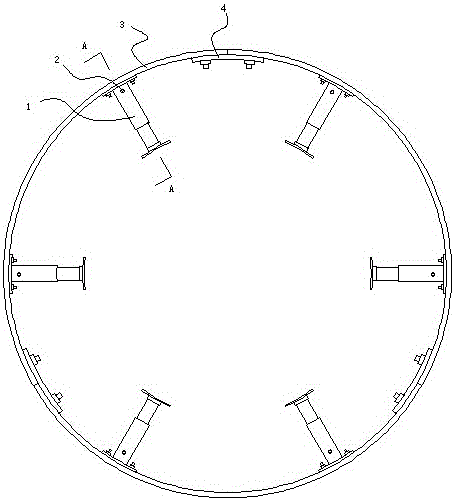

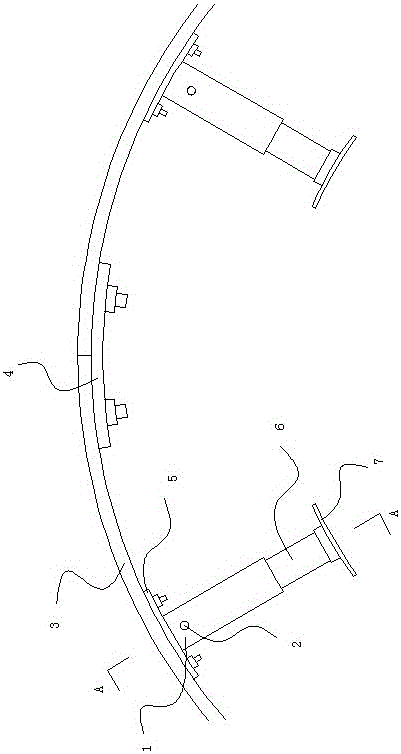

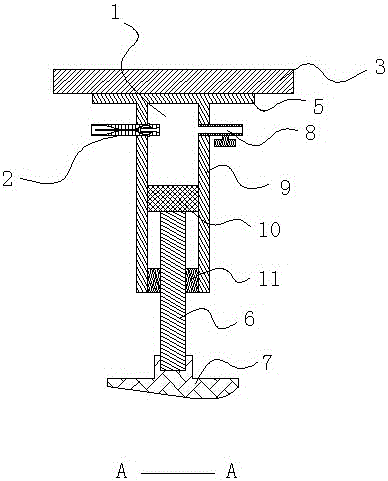

[0023] Such as figure 1 , figure 2 , image 3 As shown, this embodiment includes a cylinder formed by connecting three main body arcs 3 , and the adjacent main body arcs 3 are detachably fixedly connected by connecting structures. Both ends of the main body arc 3 are provided with connecting screws (not marked), the connecting screw (not marked) is located on the side of the main body arc 3 facing the center of the circle, and the connecting screw (not marked) is integrally cast with the main body arc 3; the connection The structure includes a connecting screw (not marked), a connecting arc 4, and a connecting nut (not marked). The connecting arc 4 is provided with a through hole (not shown) for the connecting screw (not marked) to pass through; the adjacent main body circle Arc 3 is fixedly connected by connecting screw rod (not marked), connecting arc 4 and connecting nut (not marked).

[0024] Two oil cylinders 1 are arranged on each main body arc 3, and oil cylinder 1 ...

Embodiment 2

[0027] Such as Figure 4 , Figure 5 , Figure 6 As shown, this embodiment includes a cylinder formed by connecting three main body arcs 3 , and the adjacent main body arcs 3 are detachably fixedly connected by connecting structures. The main body arc 3 includes a support section 3-1 in the middle and connecting sections 3-2 at both ends; the radial thickness of the main body arc 3 is at the junction of the connecting section 3-2 and the supporting section 3-1. Step, the radial thickness of the connecting section 3-2 is thinner than the radial thickness of the supporting section 3-1; the connecting section 3-2 is provided with a connecting screw (not marked) on the side facing the center of the circle, and the connecting screw (not marked) is connected with the connecting Section 3-2 is integrally cast. The connection structure includes a connecting screw (not marked), a connecting arc 4, and a connecting nut (not marked), and the connecting arc 4 is provided with a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com