A fully automatic online product refueling mechanism

A refueling mechanism and fully automatic technology, which is applied in the direction of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of insufficient control of refueling volume, inaccurate refueling position, low safety factor, etc., and achieve accurate and controllable movement positions , Reduce labor intensity, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

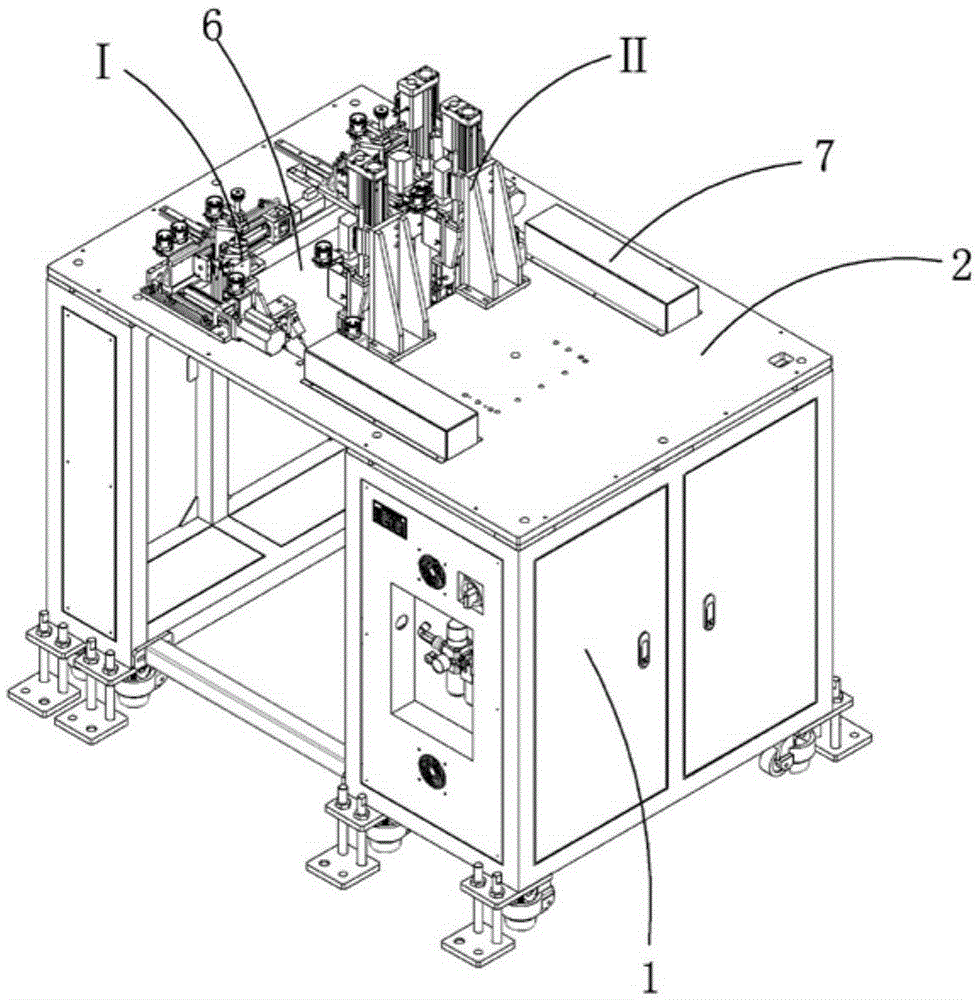

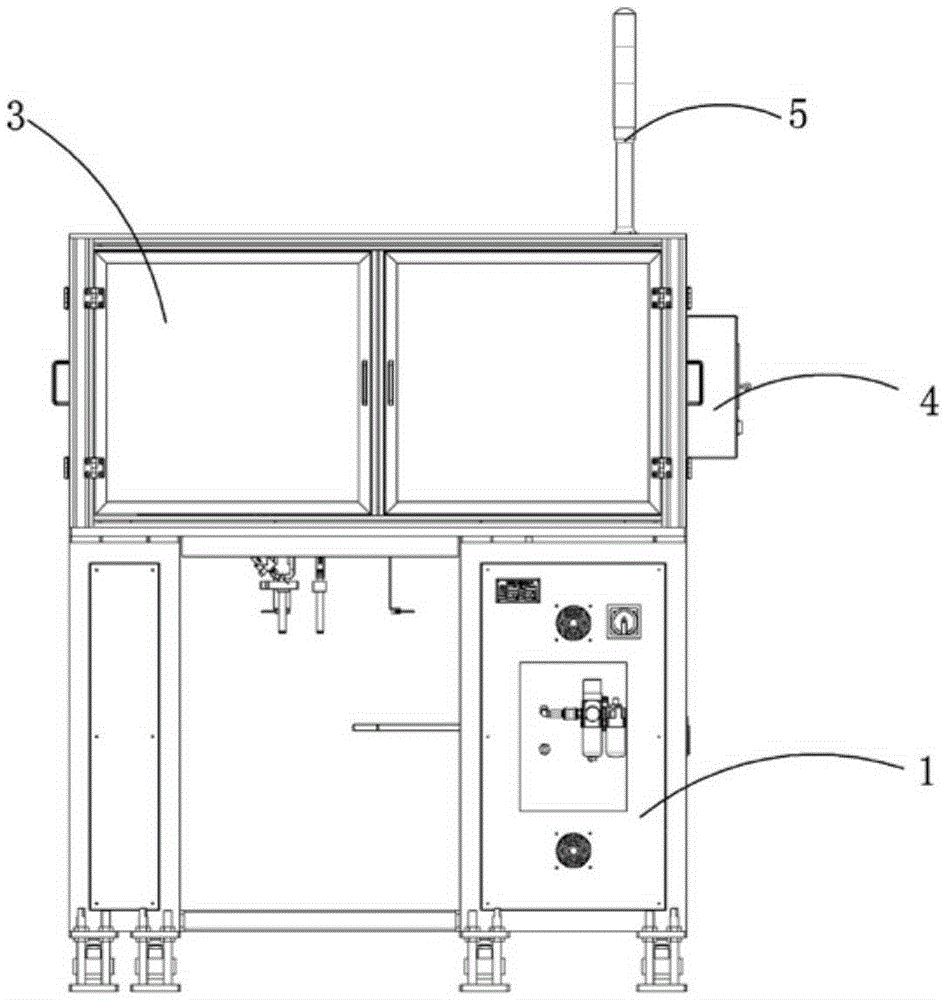

[0027] Examples, see attached Figure 1~4 , a fully automatic online product refueling mechanism, which includes a frame 1, universal wheels and a frame support base are installed on the bottom of the frame, which is convenient for fixing and moving the equipment, a base 2 is installed on the frame, and a base is installed on the base There is a machine cover 3 on which a control panel 4 and a sensor 5 are installed. The control panel has a built-in program to control the position of refueling is different, and the sensor can timely feedback the working status of the equipment; There are two groups of grasping mechanisms I and two groups of fueling mechanisms II installed on the edge of the hole, each group of grasping mechanisms corresponds to a group of fueling mechanisms, and two sets of wiring grooves 7 are installed on the base to facilitate the arrangement of wires and cables.

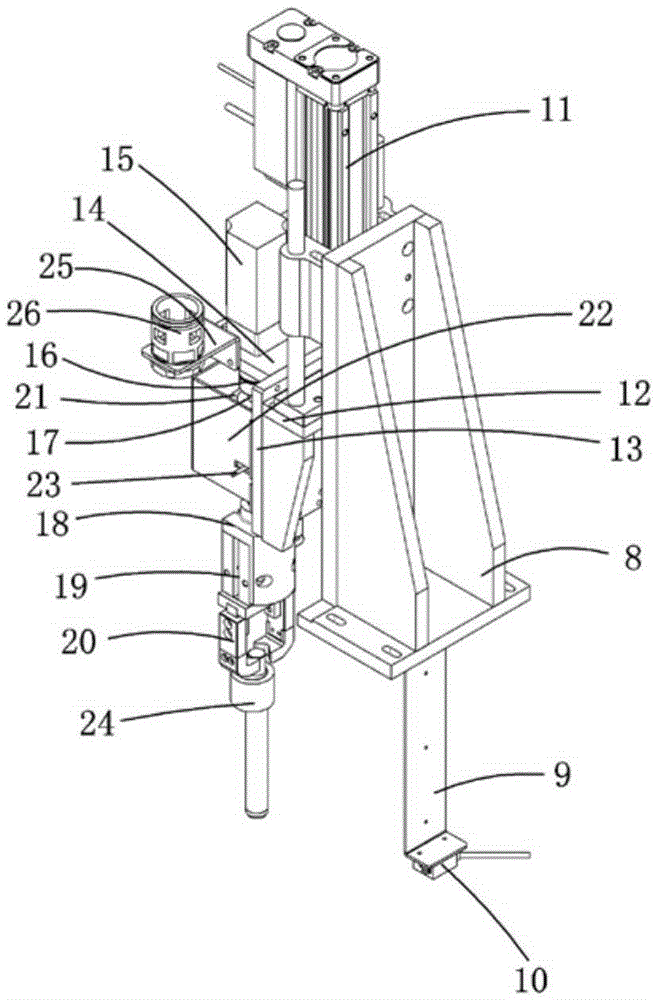

[0028] Described grasping mechanism comprises supporting base 8, and supporting base is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com